Are you in the market for a welding fixture table that meets your fabrication needs? Whether you're a seasoned welder or just starting out, finding the right welding table can significantly enhance your productivity and precision. In this guide, we delve into the essentials of welding fixture tables and highlight some top picks that cater to different preferences and budgets.

Understanding Welding Fixture Tables

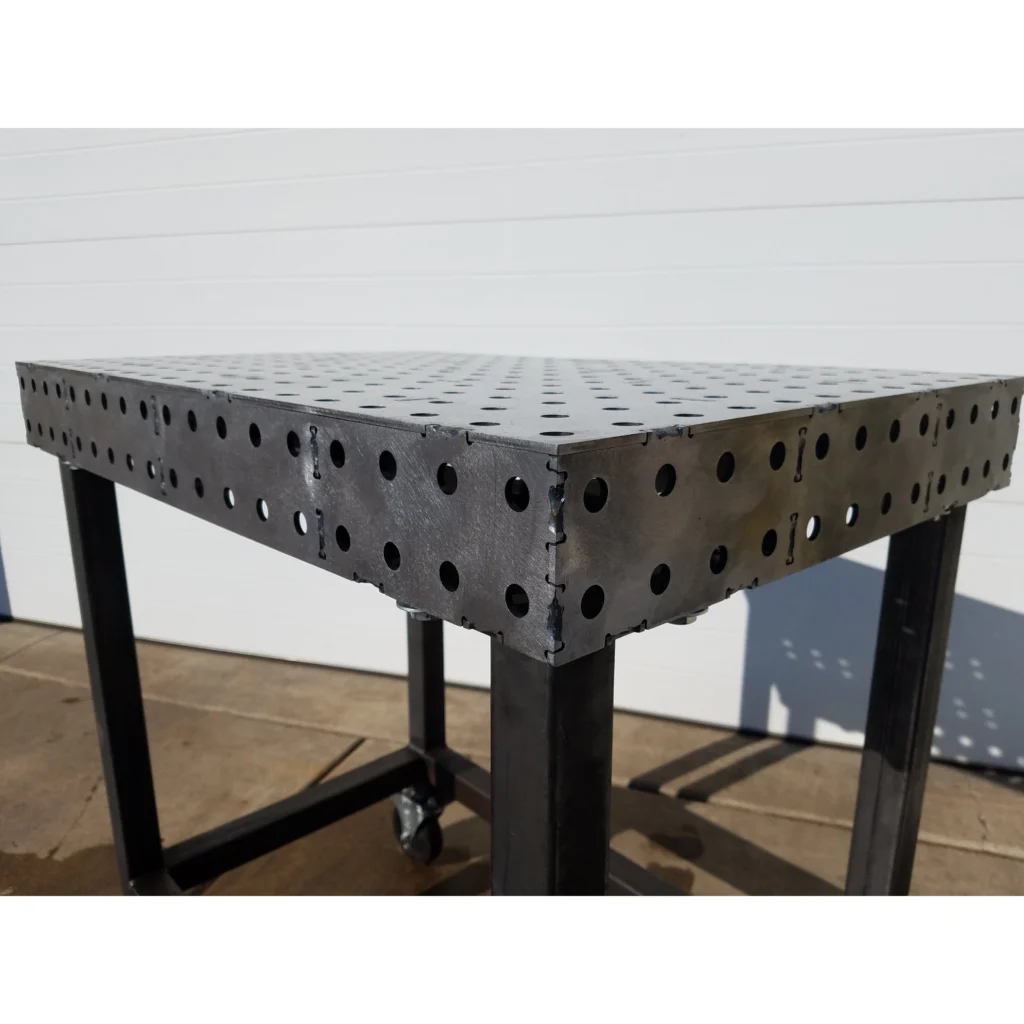

Welding fixture tables are essential tools in metalworking and fabrication. They provide a stable platform for welding, assembly, and other machining tasks. These tables come in various materials such as steel, cast iron, and aluminum, each offering unique benefits in terms of durability, heat resistance, and weight.

Key Features to Consider

When choosing a welding fixture table, several features should influence your decision:

- Material: Steel welding tables are known for their strength and durability, making them ideal for heavy-duty applications. Cast iron tables offer excellent heat resistance and stability, while aluminum tables are lightweight and corrosion-resistant.

- Tabletop Design: Look for tables with a grid of holes for versatile clamping options. Some tables come with 3D welding clamps or integrated fixtures that enhance flexibility and efficiency in positioning workpieces.

- Size and Portability: Consider the dimensions of the table to ensure it fits your workspace. Portable options with wheels or foldable legs are beneficial for workshops with limited space or those requiring mobility.

Top Picks for Welding Tables

1. Steel Welding Tables

Steel welding tables are popular for their robustness and suitability for heavy welding tasks. They often feature precision-machined tops with a grid of holes compatible with various clamping systems. The Steel Welding Table XYZ (link) is a standout choice, offering durability and flexibility at a competitive price point.

2. Cast Iron Welding Tables

For applications requiring high heat resistance and minimal vibration, cast iron welding tables excel. The Cast Iron Welding Table ABC (link) combines stability with a machined surface that ensures flatness and accuracy, making it ideal for precision welding projects.

3. Aluminum Welding Tables

Lightweight and corrosion-resistant, aluminum welding tables are favored for their portability and versatility. The Aluminum Welding Table UVW (link) features a modular design with adjustable legs and a grid pattern for easy setup and customization.

FAQs about Welding Fixture Tables

Q: Should I build or buy a welding table? A: While DIY welding tables offer customization, buying a professionally manufactured table ensures reliability and precision machining that may be challenging to replicate.

Q: What size welding table should I buy? A: Consider your typical workpiece size and available workshop space. Opt for a table that accommodates your largest projects without overcrowding your workspace.

Q: Where can I buy welding table accessories like clamps and fixtures? A: Many suppliers offer accessories tailored to specific welding tables. Ensure compatibility with your table's hole pattern for seamless integration.

Choosing the right welding fixture table involves assessing your specific needs in terms of material, size, and functionality. Whether you opt for a steel, cast iron, or aluminum table, prioritize durability, stability, and compatibility with your workflow. Explore our range of welding fixture tables at KT-Foundry (link), where quality meets craftsmanship. Enhance your welding efficiency today with a table designed to withstand the rigors of your workshop.