Forklifts and excavators are indispensable workhorses in various industries, from warehousing and logistics to construction and mining. However, what keeps these heavy machines balanced and stable amidst their dynamic operations? The answer lies in the often overlooked yet critical component known as the counterweight.

Forklift Counterweight: The forklift counterweight is typically positioned at the rear of the vehicle, serving as a counterbalance to the load being lifted by the forks. These counterweights are engineered to offset the weight of the cargo, preventing the forklift from tipping forward during lifting operations. To ensure optimal performance and safety, it's essential to understand what materials are commonly used to craft these counterweights.

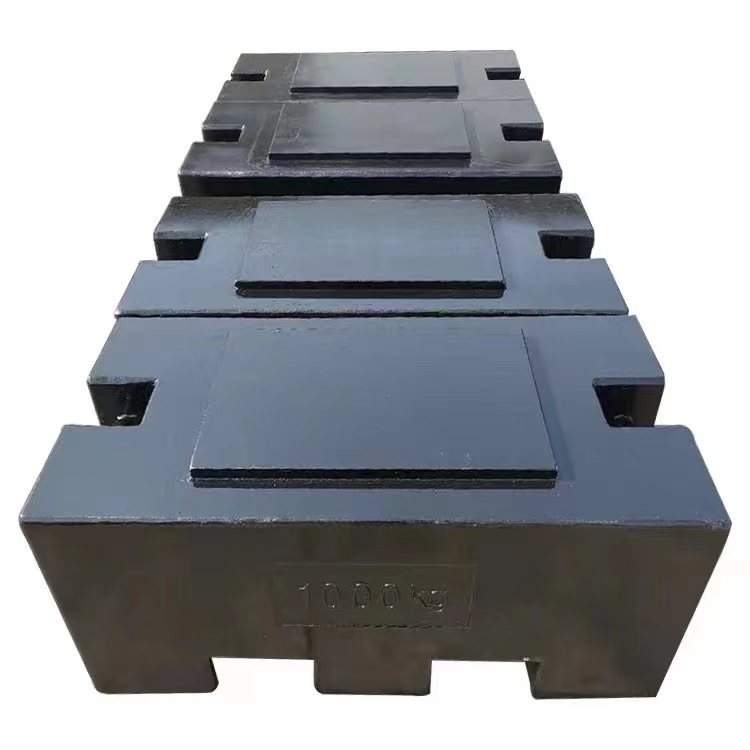

Forklift Counterweight Material: Forklift counterweights are commonly made of dense materials such as cast iron, steel, or concrete. Cast iron counterweights are favored for their high density and durability, providing substantial mass in a relatively compact form. Steel counterweights offer a balance of strength and weight, making them suitable for a wide range of forklift models and applications. Concrete counterweights, although less common, are valued for their cost-effectiveness and ability to be customized to specific weight requirements.

Excavator Counterweight: Similar to forklifts, excavators rely on counterweights to maintain stability and balance during operation. Excavator counterweights are typically located at the rear of the machine and are essential for offsetting the weight of the excavator's arm and bucket. Understanding the materials used to manufacture these counterweights is crucial for ensuring optimal performance and safety on the job site.

Excavator Counterweight Material: Excavator counterweights are often constructed from heavy-duty materials such as cast steel, lead, or concrete. Cast steel counterweights offer exceptional strength and durability, making them ideal for withstanding the rigors of heavy-duty excavation tasks. Lead counterweights, although less common, provide significant weight in a relatively small volume, making them suitable for compact excavator models where space is limited. Concrete counterweights offer a cost-effective solution for larger excavators, providing ample weight while being relatively easy to produce and customize.

Hydraulic Excavator Counterweight: Hydraulic excavators utilize hydraulic systems to power their movements, including lifting and digging. The counterweight on a hydraulic excavator is crucial for maintaining stability and preventing tipping, especially when operating on uneven terrain or lifting heavy loads. Understanding the composition of these counterweights is essential for ensuring safe and efficient operation on the job site.

At KT Foundry, we specialize in manufacturing high-quality counterweights for forklifts and excavators. Our counterweights are meticulously crafted from premium materials such as cast iron, steel, and cast steel to ensure unmatched durability and performance. Whether you're in need of a forklift counterweight, excavator counterweight, or additional weights to enhance stability, we have the expertise and capabilities to meet your needs.

Contact us today through our website (kt-foundry) to learn more about our range of counterweights and how they can benefit your operations. Let us help you elevate the safety and efficiency of your heavy machinery with our premium counterweight solutions.