DC motors are ubiquitous in various industries, powering everything from industrial machinery to household appliances. Behind their efficient operation lies a complex assembly of components, with the outer casing playing a crucial role in protecting and enhancing the performance of the motor. Let’s explore the significance of the outer casing in DC motors, delving into its functions, components, and applications.

Understanding the Outer Casing of DC Motors:

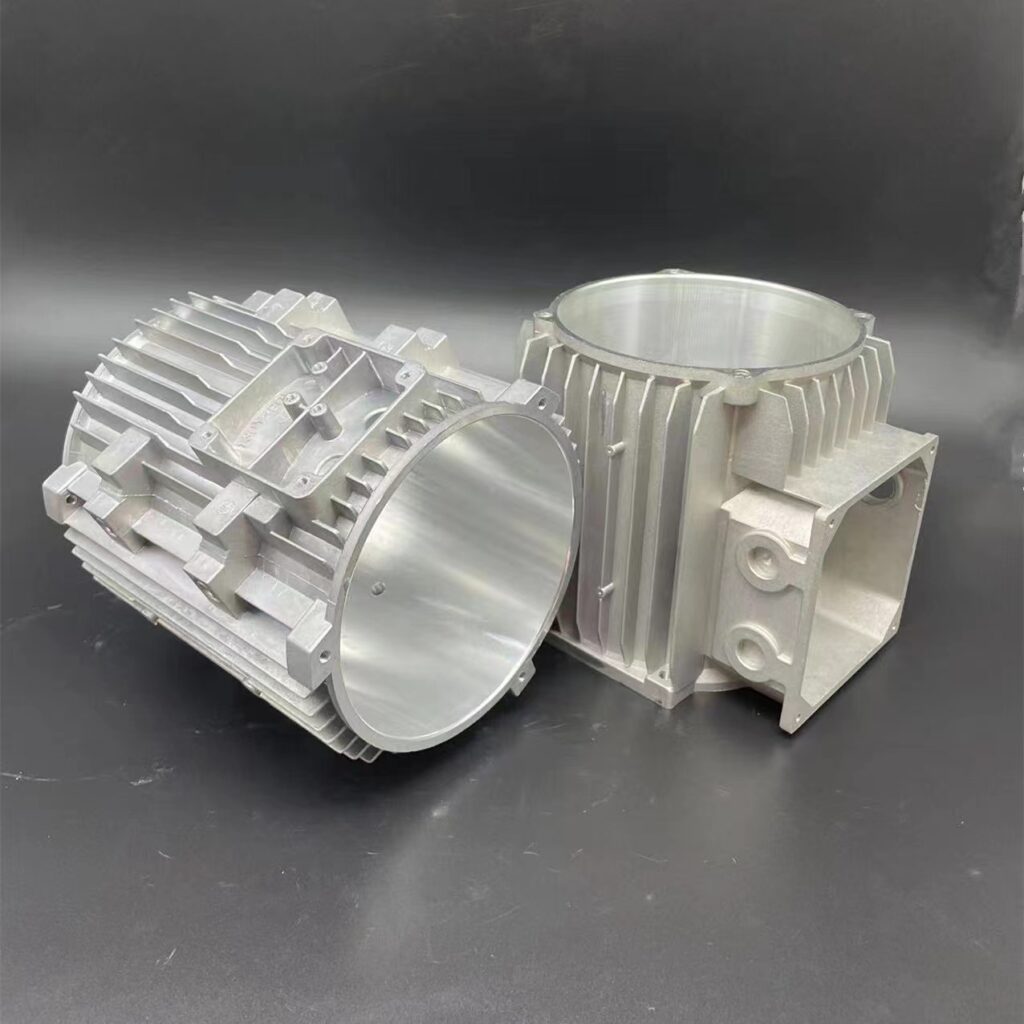

The outer casing of a DC motor serves as a protective enclosure for the internal components, including the armature, commutator, and brushes. This casing not only shields the motor from external elements but also contributes to heat dissipation, noise reduction, and overall structural integrity.

- Motor Housing: The outer casing of a DC motor is often referred to as the motor housing or motor casing. It provides a robust structure that houses the internal components and supports the motor's operation under various environmental conditions.

- Motor Housing Cover: A motor housing cover is typically included to seal the motor housing, preventing dust, moisture, and other contaminants from entering the motor assembly. This cover also facilitates easy access for maintenance and inspection of the internal components.

- Motor Housing Parts: The outer casing of a DC motor consists of various parts, such as end bells, bearing housings, and mounting flanges, which are essential for assembly and attachment to other mechanical components.

Key Functions and Features:

- Protection: One of the primary functions of the outer casing is to protect the internal components of the DC motor from damage due to external factors such as dust, moisture, and physical impact. This protection is essential for ensuring the longevity and reliability of the motor assembly.

- Heat Dissipation: DC motors generate heat during operation, primarily due to electrical resistance and friction within the moving parts. The outer casing is designed to dissipate this heat efficiently, preventing overheating and thermal damage to the motor components.

- Noise Reduction: Vibrations and mechanical noise are inherent in DC motor operation. The outer casing helps dampen these vibrations and reduce noise transmission, ensuring quieter operation in noise-sensitive environments.

Applications and Industries:

The outer casing of DC motors finds wide-ranging applications across various industries, including:

- Automotive: Powering electric vehicles, window regulators, and windshield wipers.

- Industrial: Driving conveyor belts, pumps, and machine tools.

- Robotics: Providing motion control in robotic arms and actuators.

- Aerospace: Operating actuators, servos, and landing gear systems.

From automotive to aerospace applications, DC motors equipped with robust outer casings play a vital role in powering essential systems and equipment.

Conclusion:

In conclusion, the outer casing of DC motors is a critical component that ensures the protection, heat dissipation, and noise reduction of the motor assembly. With its robust construction and functional design, the outer casing enhances the performance and reliability of DC motors across diverse industrial sectors.

For premium-quality outer casings and other motor components, visit our website (kt-foundry) to explore our extensive product range and engineering expertise.