Aluminium casting

Aluminium casting

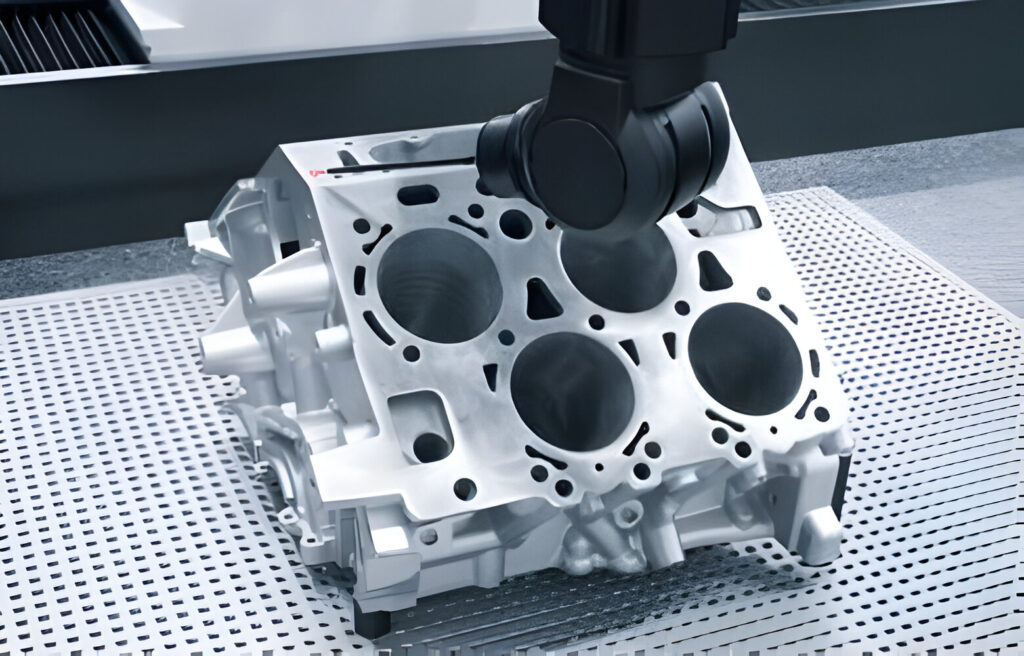

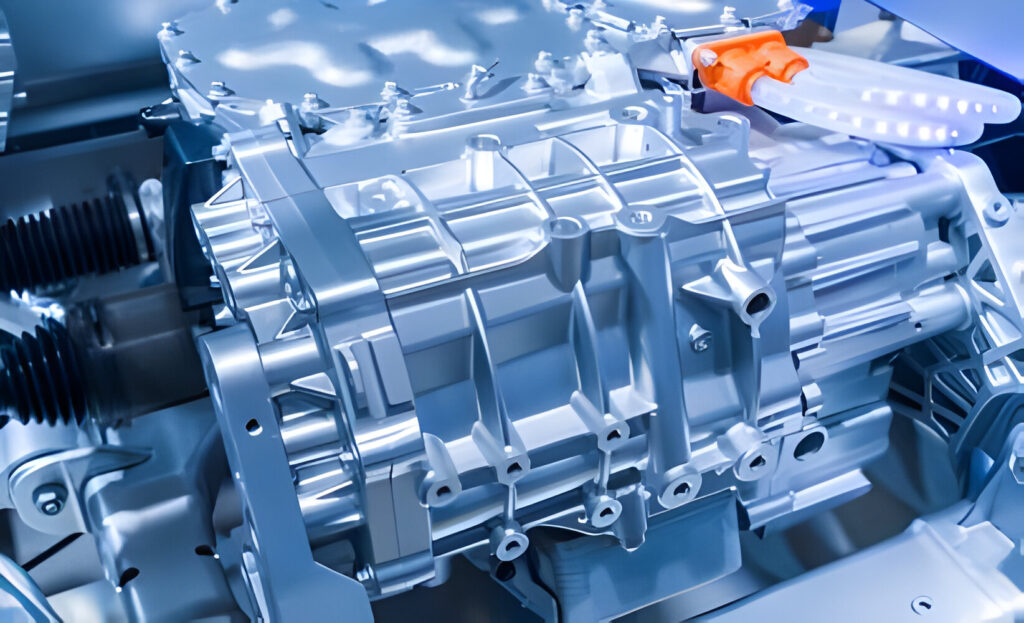

Aluminum casting is a manufacturing process in which liquid aluminum is poured into a mold to create a desired shape once it cools and solidifies. This technique is widely used in producing automotive parts, aerospace components, industrial machinery, and consumer electronics.

What are the advantages of aluminum casting?

- Lightweight: Aluminum has high strength and low density, making cast parts both strong and lightweight, suitable for applications requiring weight reduction.

- Corrosion Resistance: The natural oxide layer on aluminum provides excellent corrosion resistance, making it ideal for outdoor and harsh environment applications.

- Good Thermal and Electrical Conductivity: Aluminum offers excellent thermal and electrical conductivity, making it useful in applications requiring high heat dissipation and conductivity.

- High Malleability: Aluminum's malleability allows it to be cast into complex shapes, meeting various design requirements.

- Recyclability: Aluminum is a recyclable material, and scrap aluminum can be reused, promoting environmental sustainability and resource conservation.

Different Aluminum Casting Processes

Die Casting

Aluminum die casting is a high-efficiency metal forming process where molten aluminum is injected into a precision steel mold under high pressure, and then cooled and solidified to create the desired parts. This process is widely used in industries such as automotive, aerospace, electronics, and consumer goods. Key characteristics of aluminum die casting include:

- High Precision: Die-cast parts have high dimensional accuracy and surface quality, often eliminating the need for additional machining steps.

- Complex Shapes: Die casting can produce parts with complex shapes and intricate features, suitable for applications with strict design requirements.

- High Production Efficiency: The die casting process enables rapid mass production of parts, making it ideal for large-scale manufacturing.

- High Material Utilization: The process results in minimal material waste, ensuring high utilization of raw materials.

- Strength and Durability: Die-cast parts typically possess high mechanical strength and durability, capable of withstanding high stress and harsh environments.

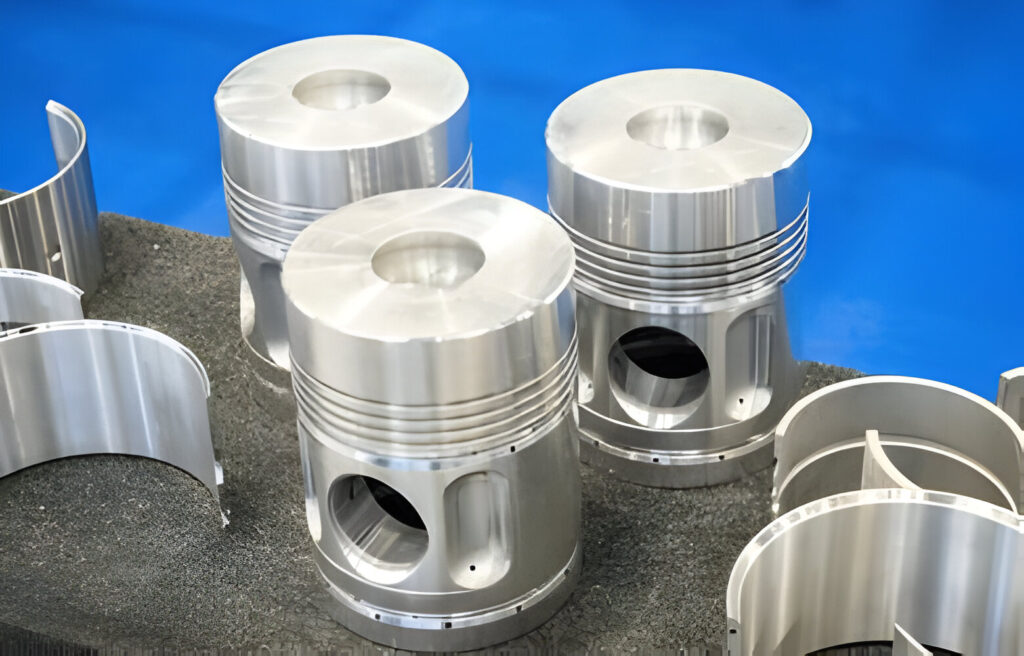

Permanent Mold Casting

Permanent mold casting, also known as gravity die casting, is a manufacturing process where molten metal is poured into a reusable mold, usually made of steel or cast iron, and allowed to solidify under the force of gravity. This method is widely used for producing high-quality metal components in industries such as automotive, aerospace, and manufacturing. Key characteristics of permanent mold casting include:

- Reusability: The molds used in this process are durable and can be reused multiple times, making it cost-effective for medium to high-volume production runs.

- High Quality: Parts produced through permanent mold casting have good dimensional accuracy, excellent surface finish, and superior mechanical properties.

- Complex Shapes: The process allows for the production of parts with intricate shapes and fine details, which may not be achievable with other casting methods.

- Consistency: Permanent mold casting provides consistent part quality from batch to batch, ensuring uniformity in large-scale production.

- Reduced Porosity: The slow cooling rate in permanent mold casting often results in parts with fewer gas pockets and reduced porosity, enhancing their strength and reliability.

Our aluminum casting products

Office Chair Metal Base

Aluminium casting

Aluminium piston

Leading Aluminium casting Manufacturers and Companies

KT-Foundry is a leading manufacturer in the aluminum casting industry, renowned for our precision, quality, and innovation. Our state-of-the-art facilities and advanced manufacturing techniques enable us to produce high-quality aluminum castings that meet the stringent requirements of various industries, including automotive, aerospace, and electronics. At KT-Foundry, we pride ourselves on delivering exceptional products with superior dimensional accuracy, excellent surface finishes, and outstanding mechanical properties. Our commitment to sustainability and efficiency ensures that we maximize material utilization and minimize waste. Partner with KT-Foundry to experience the benefits of our expertise and dedication to excellence in aluminum casting.

Please fill out the form below to get started with your project.