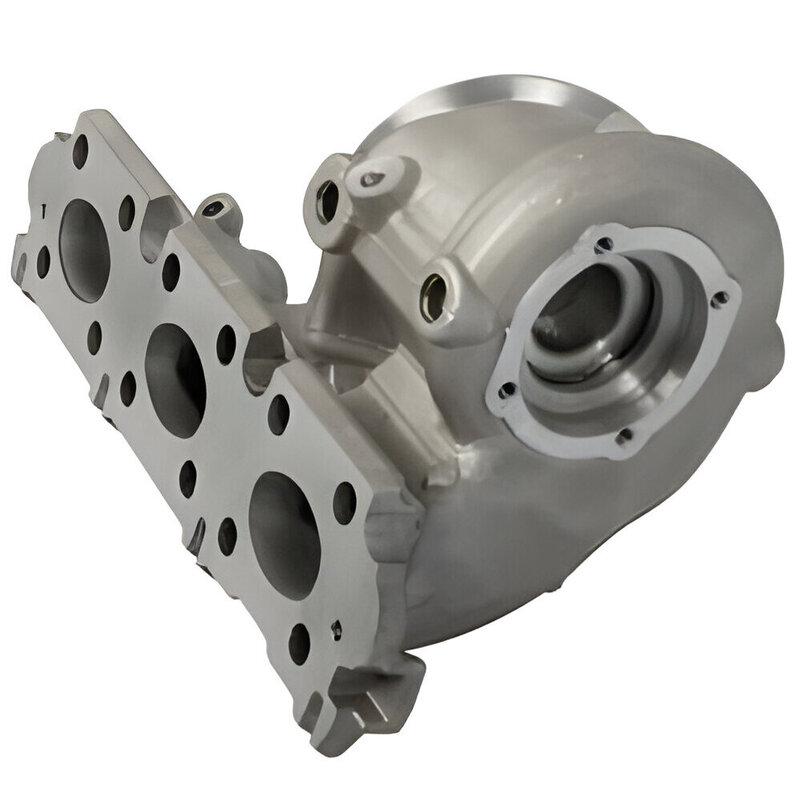

When it comes to manufacturing high-performance air exhaust manifolds, aluminum alloy casting stands out as a premier choice due to its remarkable properties and versatility. This article delves into the benefits, applications, and manufacturing processes of aluminum alloy casting air exhaust manifolds, with a focus on how they compare to stainless steel options. We will also highlight why you should consider our products for your next project.

Advantages of Aluminum Alloy Casting Air Exhaust Manifolds

Aluminum alloy castings are known for their lightweight nature and excellent thermal conductivity, making them ideal for exhaust systems. These properties ensure that the exhaust manifold can effectively manage the heat generated by the engine, thus enhancing performance and longevity. Additionally, aluminum alloys are resistant to corrosion, which significantly extends the life of the manifold in harsh environments.

Manufacturing Process

The manufacturing of aluminum alloy casting air exhaust manifolds involves several key steps to ensure the highest quality and performance:

- Mold Design and Preparation: The process begins with designing a precise mold, which is crucial for achieving the desired shape and specifications. Advanced software and simulations are often used to refine the design before moving to production.

- Casting: In this stage, molten aluminum alloy is poured into the prepared mold. This step must be meticulously controlled to avoid any impurities and ensure a uniform material structure. Sand casting exhaust manifolds are a popular method used due to their ability to produce complex shapes with fine details.

- Cooling and Solidification: Once the alloy is cast, it is allowed to cool and solidify. The cooling rate can affect the final properties of the manifold, so it is carefully monitored and controlled.

- Finishing: After the casting is complete, the manifold undergoes finishing processes such as machining, heat treatment, and surface coating to enhance its performance and durability.

Applications and Scenarios

Aluminum alloy casting air exhaust manifolds are widely used in various automotive and industrial applications due to their superior performance characteristics. They are particularly favored in high-performance vehicles where weight reduction and efficient heat management are critical. Additionally, these manifolds are used in marine engines, aerospace applications, and heavy machinery, where their corrosion resistance and durability are highly valued.

Comparatively, stainless steel exhaust manifolds and stainless steel turbo manifolds are also popular choices, especially in high-stress environments where strength and heat resistance are paramount. While aluminum excels in weight and thermal conductivity, stainless steel offers exceptional durability and resistance to high-temperature oxidation.

Why Choose Us?

At KT Foundry, we specialize in producing high-quality aluminum alloy casting air exhaust manifolds tailored to meet your specific needs. Our products are manufactured using state-of-the-art technology and rigorous quality control measures to ensure optimal performance and reliability. We work closely with stainless steel exhaust manifold manufacturers to offer a comprehensive range of solutions, including exhaust manifold stainless steel options for customers who require them.

By choosing our aluminum alloy casting air exhaust manifolds, you benefit from:

- Customizable Designs: We can tailor the design and specifications to suit your application, ensuring a perfect fit and optimal performance.

- High-Quality Materials: Our use of premium aluminum alloys guarantees long-lasting durability and excellent thermal management.

- Competitive Pricing: We offer competitive pricing without compromising on quality, providing you with the best value for your investment.

For more information or to place an order, visit our website at kt-foundry. Our team of experts is ready to assist you with any inquiries and help you find the perfect solution for your exhaust system needs.