Ball Valves Casting

Ball Valves Casting

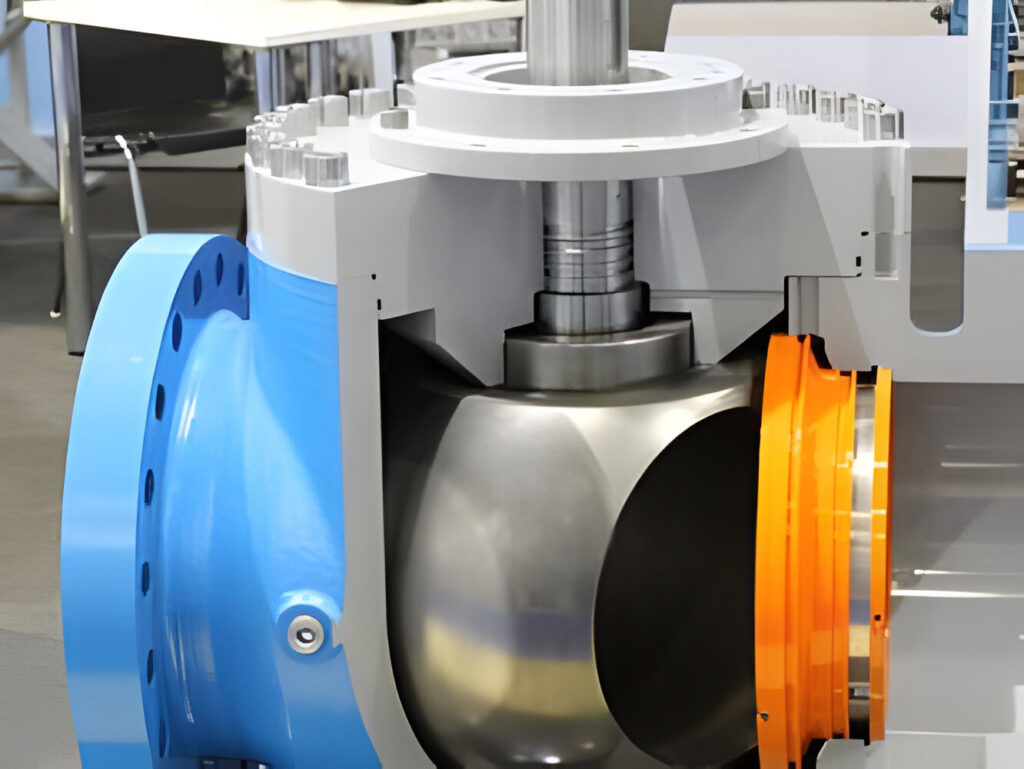

Ball valve casting refers to the process of manufacturing ball valves through casting, which involves pouring molten metal into a mold to create the valve's components. Ball valves are quarter-turn valves that use a hollow, perforated, and pivoting ball to control flow through it.

In the casting process, a mold is created in the shape of the valve components, such as the ball and the valve body. Molten metal, often stainless steel, brass, or bronze, is then poured into the mold and allowed to solidify. Once solidified, the mold is removed, leaving behind the casted ball valve components.

Casting is a common method used in the manufacturing of ball valves due to its ability to produce complex shapes with high precision. The resulting valves are durable, reliable, and suitable for a wide range of applications, including oil and gas, water treatment, and industrial processes.

ball valve casting at KT-Foundry

At KT-Foundry, we specialize in ball valve casting, delivering components of exceptional quality and precision. Our commitment to using premium materials and continuous innovation ensures that our ball valves meet the highest standards of performance and durability. Trust KT-Foundry for reliable and long-lasting valve solutions.