In the maritime world, bollard ships are key to safe mooring. Bollards are vital on ships, docks, and ports. They provide secure spots for mooring lines to keep vessels steady. Knowing about bollard ships is important for those in maritime logistics and operations.

Key Takeaways

- Bollards are essential for secure mooring of ships in ports and harbors.

- Bollard ships are designed with specific features to handle mooring lines efficiently.

- The size, material, and construction of bollards are tailored to the vessel's requirements.

- Proper placement and orientation of bollards are crucial for effective line management.

- Factors like vessel size and environmental conditions influence the selection of the right bollard system.

Understanding the Importance of Bollard Ships

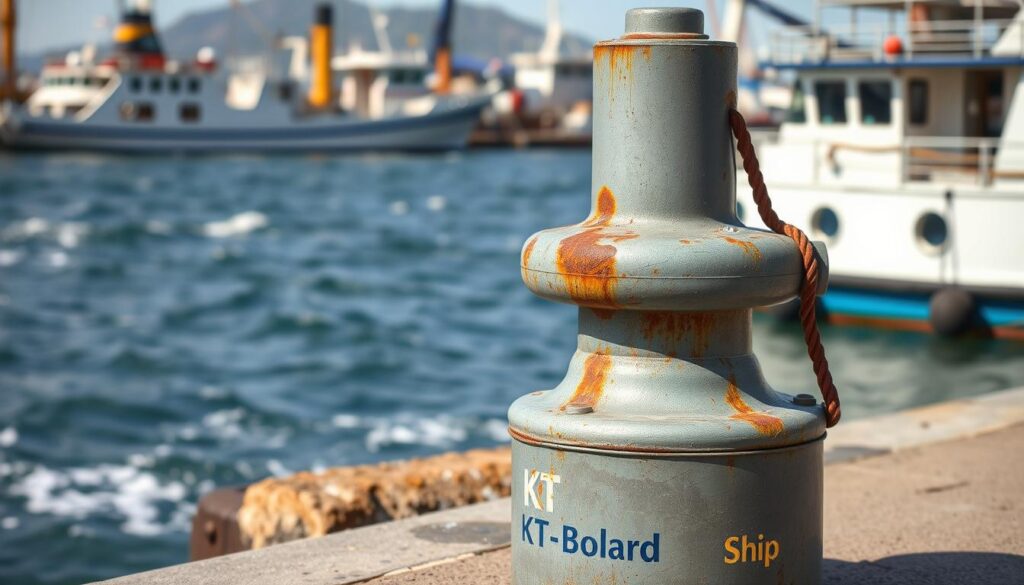

Bollard ships are key in maritime operations. They act as anchors for mooring lines, keeping vessels steady. Made from cast iron or steel, they handle the forces from mooring lines well. This ensures safe and efficient mooring operations.

They are placed on ships, docks, and ports. This makes them a reliable and strong solution for securing vessels during mooring system applications.

These essential parts help keep ships stable and in control during mooring operations. They are used by all kinds of vessels, big and small. This lets them moor safely and efficiently in many places.

Pivotal Role in Maritime Operations

Bollard ships are crucial in the maritime world. They are the base for safe vessel mooring. Designed by KT-Foundry, they ensure ships operate safely and efficiently in ports and harbors.

Safe and Efficient Mooring

The bollards are typically set at key points for mooring lines. This makes it easy for crews to attach lines, even at high angles. The right placement of cleat bollards and other different mooring solutions keeps ships stable. This prevents accidents and ensures smooth operations.

Types of Marine Bollards and Their Applications

In the maritime world, choosing the right marine bollards is key. They help secure vessels, from small boats to big ships. Each type is made for different sea environments.

Cast iron and steel bollards are very common. They are strong and last a long time. They work well in areas with big tides, keeping boats safe and steady.

- Cast iron and steel bollards are reliable and last long in many sea settings.

- They are perfect for big boats that need strong mooring to handle their size and weight.

There are also special bollard designs like T-head and cleat bollards. They are made for easy use and meet specific needs of different boats. This makes mooring easier and more efficient.

"The unique demands of each maritime environment require a diverse range of bollard types to ensure the safe and reliable mooring of vessels."

No matter the type, bollards are vital for keeping vessels stable, especially in tough tidal areas or for big ships. Choosing the right bollard ensures safe and efficient mooring for maritime operators.

Commonly Used Bollard Designs: T-Head, T-Horn, Kidney, Cleat, Double Bitt, Single Bitt, and Pillar

T-Head Bollard: This design offers excellent stability and strength, making it ideal for heavy-duty applications. Its flat top allows for easy securing of lines.n

T-Horn Bollard: Similar to the T-Head but features extended arms, providing additional tie-off points. This versatility is beneficial for vessels with multiple mooring lines.n

Kidney Bollard: With its curved shape, the Kidney bollard is designed to minimize wear on mooring lines. It’s effective for moderate loads and allows for smooth line handling.n

Cleat Bollard: Known for its ease of use, the Cleat bollard provides multiple securing points for lines. It is particularly useful in recreational boating.n

Double Bitt Bollard: This design features two vertical posts, offering enhanced stability and the ability to handle heavy loads. It’s commonly used in commercial shipping and docking.n

Single Bitt Bollard: A simpler design with one vertical post, it is lightweight and easy to handle, making it suitable for smaller vessels and less demanding applications.n

Pillar Bollard: With a robust and tall structure, the Pillar bollard is designed for high-load applications. It provides excellent visibility and accessibility for securing lines.

Each of these designs offers unique benefits suited to various mooring needs, ensuring safety and reliability in marine operations.Design Tailored to Specific Vessel Size

Materials and Construction

Bollards are made from strong materials like cast iron or steel. They are built to last in the sea's harsh conditions. Advanced metal techniques are used to make them strong against mooring forces.

By placing bollards on decks or quays, vessels are safely moored. This makes loading and unloading easier. As a top marine equipment maker, we focus on safety and durability in our bollard ships.

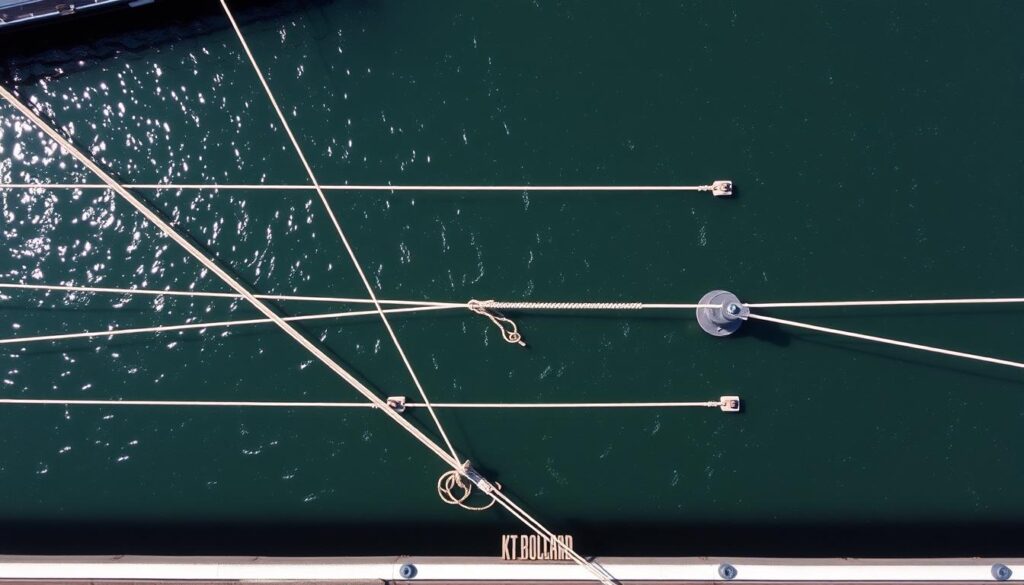

Mooring Line Angles and Bollard Placement

The way we place bollards is key to good mooring. Bollards handle different mooring line angles for various vessels. This makes sure mooring lines run smoothly without too much stress.

Choosing where to put bollards depends on the types of vessels, the mooring area, and how easy it is for operators. By placing bollards wisely, we make mooring safer and more efficient. This makes it easier to moor boats and manage mooring lines.

| Mooring Line Angle | Bollard Positioning | Advantages |

|---|---|---|

| Acute Angle | Closer Spacing | Better line control, reduced strain |

| Obtuse Angle | Wider Spacing | Accommodates larger vessels, increased versatility |

| Perpendicular | Balanced Spacing | Optimal line management, suitable for most vessels |

By thinking about mooring line angles and placing bollards smartly, we make a mooring system that works well for many vessel types and sizes. This focus on detail makes maritime operations safer and easier.

"The optimal positioning of bollards is essential for effective line management, ensuring that mooring lines are able to run freely and without excessive strain or wear."

Factors Influencing Bollard Selection

Choosing the right bollard is key in maritime operations. It affects both safety and efficiency when mooring boats. Several important factors guide the selection of the right bollard for each job.

Vessel Size and Environmental Conditions

The size and weight of vessels are major factors. Larger vessels need bollards with higher capacities for secure mooring. Smaller boats can be secured with more compact bollards.

The environment where boats are moored also matters. Things like tidal range, wind, and waves are important. These conditions affect the choice of bollard.

When picking a bollard, consider the choice of bollard and the types of marine bollards out there. Also, think about the capacities to suit each maritime setting. Bollards come in materials like cast iron and steel, ready to handle the marine environment. They are vital for mooring both larger vessels and smaller vessels.

Maritime operators should weigh these factors carefully. This ensures the chosen bollards play a crucial role in the mooring area. They provide the ease of use and reliability needed for operations, no matter the tidal range or other environmental conditions.

"The selection of the right bollard is essential for ensuring the safe and efficient mooring of vessels, regardless of their size or the environmental conditions of the mooring area."

Safety and Durability Considerations

At the heart of a good bollard ship is a strong focus on safety and durability. These structures must be built to withstand the forces applied by mooring lines. This prevents accidents and potential harm to both vessels and people. Bollards are made from ductile materials like cast iron or steel. They use metal casting or welding techniques to last long and stay strong.

The placement and configuration of bollards are key to safe and efficient management of mooring lines. They ensure that vessels are securely anchored. This is especially important for large vessels in ports and harbors, where environmental conditions and available space can be tough.

Preventing Accidents and Potential Harm

We, as a leading manufacturer of marine equipment, know how crucial safety is. Our bollards are made to secure vessels safely and efficiently. They are designed for both smaller boats and large vessels. Our ductile bollards are built to withstand the forces applied and keep your anchor point firmly fixed on the deck.

| Feature | Benefit |

|---|---|

| Durable Construction | Withstand the forces applied by mooring lines |

| Ductile Materials | Prevent accidents and potential harm |

| Optimal Placement | Ensure efficient line management and secure anchoring |

"Our bollards are engineered to keep your vessels securely anchored, no matter the environmental conditions or available space."

Choosing the Right Bollard for Your Maritime Operations

Choosing the right bollard is key for safe and efficient mooring. There are many types of marine bollards, each for different maritime needs.

When picking a bollard, think about the boat's size and weight. Also, consider the mooring area's environment and your maritime operation's needs. It's important for the bollard to handle mooring lines well and support large vessels.

The tidal range and environment are also crucial. Cast iron and steel bollards are top choices for their strength and durability in various maritime settings.

Knowing how bollards work in your operations is vital. It helps make a smart choice that keeps your mooring safe and efficient.

| Bollard Type | Suitable for Vessel Size | Tidal Range Capacity | Ease of Use |

|---|---|---|---|

| Cast Iron Bollard | Larger Vessels | High Tidal Range | Moderate |

| Steel Bollard | Smaller Vessels | Low to Moderate Tidal Range | High |

"Selecting the right bollard is essential for ensuring the safety and efficiency of our maritime operations."

The Role of Bollard Ships in Ports and Harbors

Bollard ships are key in ports and harbors, acting as anchors for vessels. They are made from strong materials like cast iron or steel. These structures handle the forces from big ships and the weather.

Their placement is crucial for managing mooring lines. This ensures cargo is loaded and unloaded safely and efficiently.

In ports and harbors, space is tight. Using fewer than 10 bollards can prevent accidents. They keep vessels from moving and keep everyone safe.

Bollard ships are the anchor points for all kinds of ships. They help avoid line failures, keeping vessels moored safely.

Ensuring Safe and Efficient Loading and Unloading

The right placement of bollard ships is vital for managing mooring lines. They allow for secure line attachment. This makes loading and unloading cargo safe and smooth.

By stopping vessels from moving, bollard ships keep maritime operations safe and productive.

Ports and harbors depend on bollard ships for smooth goods flow and safe vessel berthing. These anchor points are designed and placed with care. They make loading and unloading efficient and safe, helping maritime operations succeed.

Conclusion

In the world of maritime operations, bollard ships are key for safe and efficient mooring. They are made of strong materials like cast iron and steel. These structures give ships a secure place to tie up in ports and harbors.

Knowing about bollard ships helps us choose the best ones for our needs. This choice is important for the safety and efficiency of our maritime work.

At KT-FOUNDRY, we specialize in the production of high-quality bollards for ships, designed to ensure safety and reliability in marine environments. Our bollards are manufactured using advanced casting techniques and high-strength materials, providing exceptional durability and resistance to harsh weather conditions and marine corrosion. With a commitment to precision engineering and strict quality control, we deliver bollards that meet industry standards and customer specifications. Additionally, we offer customization options to cater to specific maritime needs, ensuring optimal performance in every application.

To help us understand your requirements better, please fill out the form below, and we will provide a tailored solution just for you.