Carbon steel casting

What is carbon steel casting?

Carbon steel is one of the primary materials used in the steel casting industry. It can be classified into three main types based on its carbon content:

Low-Carbon Steels (< 0.20% C):

- These steels offer a range of tensile properties through heat treatment.

- They can be hardened to achieve high surface hardness with excellent abrasion resistance and good core ductility.

Medium-Carbon Steels (0.20 to 0.50% C):

- This composition provides increased durability, pliability, and strength.

- A variety of tensile strengths can be achieved, coupled with good ductility and impact resistance.

- These steels are easily machined in a softened condition.

High-Carbon Steels (> 0.50% C):

- Known for their high strength and good shape memory, making them ideal for spring manufacturing.

- These steels are subject to wear and abrasion, making them suitable for high-strength and heavy-duty applications.

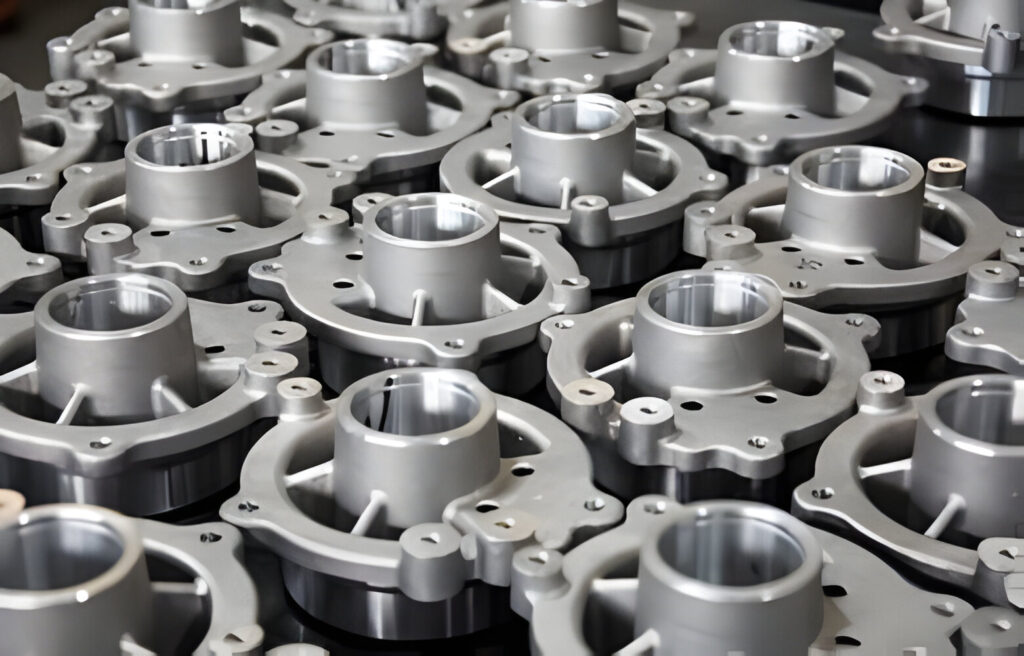

Our list of carbon steel castings

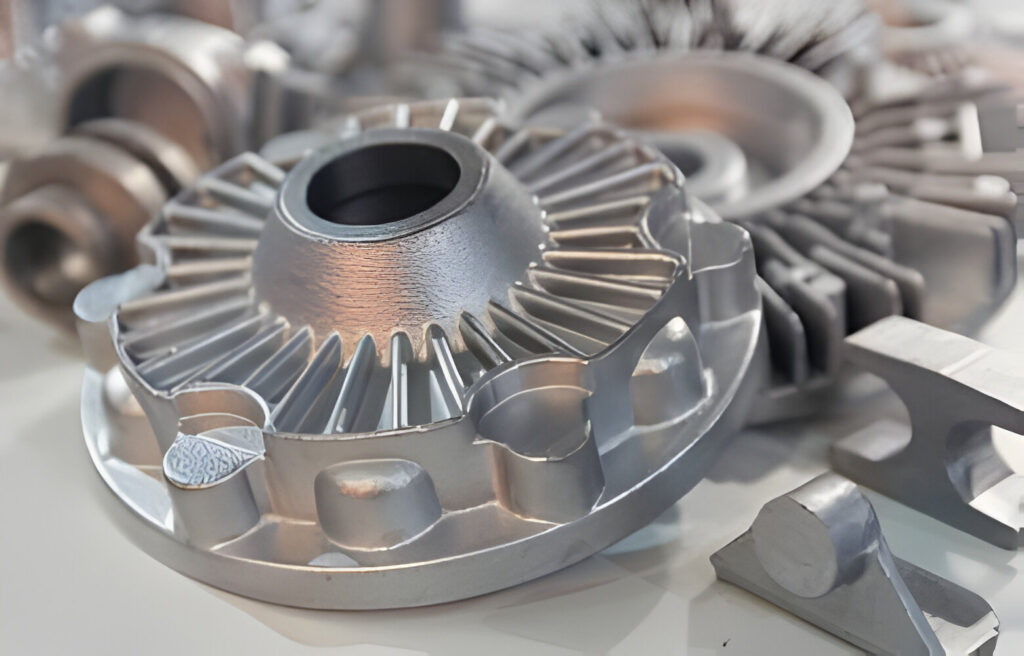

Carbon Steel Casting Process

The carbon steel casting process involves several techniques to create precise and durable parts. Three primary methods used in the industry are:

Water Glass Investment Casting:

- Uses water glass (sodium silicate) as the binder.

- Produces complex shapes with good surface finish and dimensional accuracy.

- Cost-effective for medium to large components.

Silica Sol Investment Casting:

- Uses silica sol as the binder.

- Provides superior surface finish and precision.

- Ideal for intricate and small parts with tight tolerances.

Shell Molding Casting:

- Forms a thin shell of sand and resin around a heated pattern.

- Offers excellent dimensional accuracy and surface finish.

- Suitable for high-volume production of complex shapes.

Benefits of Carbon Steel Castings

Carbon steel castings are highly valued for their strength and durability, making them ideal for heavy-duty applications across various industries, including automotive, construction, machinery, and tools. Their cost-effectiveness is another significant advantage, as carbon steel is relatively inexpensive compared to other metals. The casting process provides the flexibility to create complex shapes and sizes, tailored to meet specific requirements. Additionally, carbon steel castings can be heat treated to enhance their mechanical properties, such as hardness and tensile strength. Their excellent machinability allows for further processing and finishing, ensuring the final product meets precise specifications.

Carbon Steel Casting Manufacturer

At KT-Foundry, we excel in manufacturing high-quality carbon steel castings. Our advanced techniques, including water glass investment casting, silica sol investment casting, and shell molding casting, ensure precision and durability in every component. We cater to diverse industries such as automotive, construction, and machinery, providing cost-effective and reliable solutions. Our state-of-the-art facilities and experienced engineers guarantee superior performance and longevity in all our castings.