Choosing the right material for manufacturing is crucial for achieving both performance and cost efficiency. Cast iron and steel are two of the most widely used materials in industrial applications, each offering distinct advantages depending on the project. At KT-FOUNDRY, we specialize in both cast iron and steel solutions, helping our clients make informed material choices based on their unique project needs.

Understanding the strengths of each material can make a substantial difference in your project outcomes. In this guide, we’ll break down when to choose cast iron over cast steel and vice versa, discuss common scenarios, and provide tips for ensuring you make the best procurement decision.

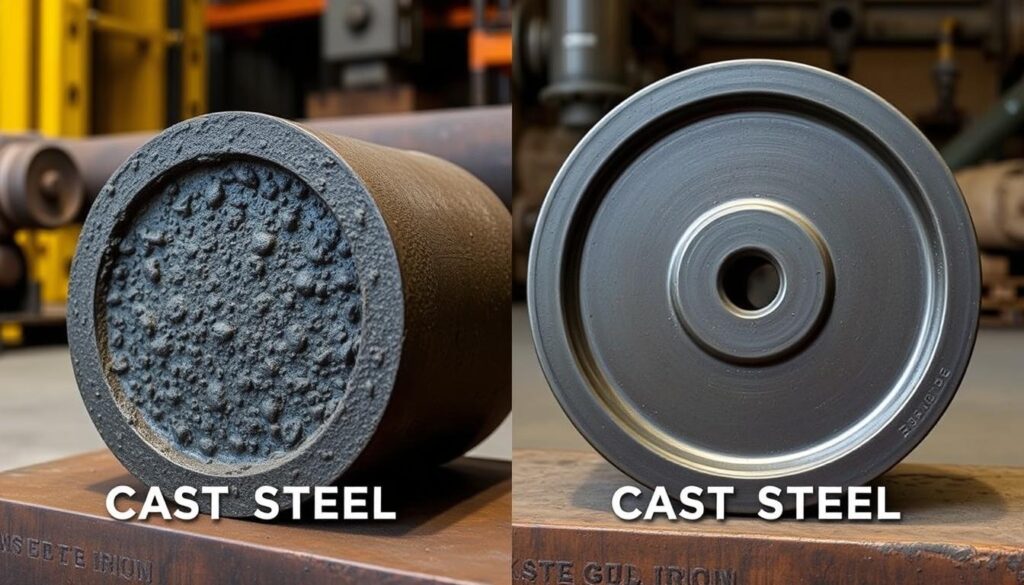

When choosing between cast iron and steel, consider strength, melting points, and how they resist corrosion. Each material has its own strengths and weaknesses. We can guide you to choose the right one for your needs and budget.

Introduction

Cast iron and steel are key materials in the manufacturing world. Each has its own strengths and benefits. Knowing the differences is key to picking the right one for your project. We'll look at what makes cast iron and steel special and why choosing wisely matters.

Cast Iron and Steel: An Overview

Cast iron is famous for its strength and ability to hold heat well. It's used in many fields, like heavy machinery and cars. On the other hand, steel is known for its strength and flexibility. It's great for projects needing durability and resilience.

Choosing between cast iron and steel can greatly affect your project's success. Things like cost, performance, and how long it lasts depend on the material. So, it's important to think carefully before deciding.

"Proper material selection is a critical step in optimizing product quality and efficiency across various industries."

Choosing cast iron over cast steel is usually based on several key considerations:

When picking the right material for a project, cast iron often wins over cast steel. This is because cast iron has special properties that make it great for many uses.

1.cost-effectiveness

The production cost of cast iron is usually lower than that of cast steel because of its simpler casting process and low raw material costs. For projects with limited budgets or applications that do not require high performance, cast iron is more economical.(Cast iron costs at least 30 percent less than cast steel)

2.Compressive strength

Cast iron is excellent at resisting pressure and is ideal for applications that withstand high pressures, such as foundation components, machine bases and pipes. Cast iron is the ideal choice if the project needs to carry heavy loads or resist static pressure.

3.Shock absorption and wear resistance

Cast iron has excellent shock absorption properties, which makes it very suitable for machine tool beds, bases and equipment with frequent vibration. In addition, cast iron has strong wear resistance, making it suitable for applications that require wear resistance, such as grinding disks, pump housings and valves.

4.Heat resistance

Cast iron materials can maintain stability at high temperatures and are often used in stoves, boilers and other applications requiring high temperature work. If the project requires high temperature materials without high toughness, cast iron is more suitable.

5.Molding complexity

Cast iron has good fluidity and can be easily cast into complex shapes. Therefore, if the design is complex and the shape is irregular, the cast iron is easier to achieve and the processing needs are reduced.

6.Long-term durability and low maintenance

Cast iron is generally very strong and durable, with a long service life and low maintenance requirements. For scenarios that require high durability and want to reduce maintenance costs, the high hardness and durability of cast iron can be well met.

7.Application matching

Cast iron has a wide record of use and excellent performance in specific applications. For example, the use of cast iron in sewage treatment, plumbing, and construction works has been proven, so the use of cast iron in these areas is more reliable and less risky.

"Cast iron's unique properties, combined with its cost-effectiveness, make it a compelling choice for a wide range of projects where durability and efficiency are paramount."

While cast steel has its own benefits, like being stronger and more resistant to impacts, cast iron's advantages often win out. This is especially true in many industrial and manufacturing fields.

Choosing cast steel over cast iron is usually based on several key considerations:

When picking a material for your project, cast steel often beats cast iron. It has higher tensile strength and ductility. Steel melts at a higher temperature (2500-2800°F) than cast iron. This gives it better impact resistance and makes it easier to weld.

1.Strength and toughness

Cast steel has high toughness and tensile strength, and can better resist impact and deformation. For applications that require high impact loads or dynamic loads (such as lifting equipment, building supports, etc.), cast steel performs better.

2.Corrosion resistance

Cast steel can be alloyed and heat treated to improve its corrosion resistance, suitable for wet, acidic or alkaline environments. Cast iron is relatively prone to rust, especially when exposed to water or chemicals for long periods of time. For more corrosive working environments, cast steel is a safer choice.

3.Weldability and machinability

The weldability and workability of cast steel are better and suitable for occasions requiring subsequent welding or fine machining. This feature has obvious advantages in situations where flexible manufacturing, adjustment or repair is required.

4.Complex shapes and precise tolerances

The high processing accuracy of cast steel is suitable for the production of parts requiring high dimensional accuracy or complex structures. For example, precision machinery, machined parts and aviation parts, cast steel is more able to meet the demand in these areas.

5.High temperature strength

Cast steel can maintain good mechanical properties at high temperatures, while cast iron is easy to become brittle at high temperatures. Therefore, in high temperature applications such as boiler pressure vessels, heat treatment equipment, etc., the performance of cast steel materials is better.

6.Fatigue strength

Cast steel has high fatigue strength under cyclic load and is suitable for occasions under repeated stress (such as bridge structures, building supports, mechanical arms, etc.). If the product will withstand long-term repeated load in the work, the service life of cast steel is longer.

7.Reliability and safety

Cast steel has good structural uniformity and low fracture risk, which is suitable for applications with high safety requirements (such as building structures, mining equipment, etc.). The performance of cast steel material is more reliable and can effectively reduce safety risks.

8.Environmental protection and durability

Although cast steel may cost more than cast iron, its durability and low maintenance requirements can lead to cost savings over the long term. In addition, the high recycling rate of cast steel makes it suitable for buyers pursuing environmental sustainability.

Even though cast iron is cheaper, cast steel is often a better choice. It's stronger, more durable, and more resilient. Knowing the differences between these materials helps you choose the right one for your project.

"Cast steel offers superior mechanical properties, making it the ideal choice for applications that demand high stress tolerance and corrosion resistance."

Project-Specific Scenarios and Best Recommendations

Choosing between cast iron and cast steel depends on your project's needs. Both materials have unique benefits. Knowing their characteristics helps pick the best one for your project.

Heavy Machinery and Equipment

Cast iron is great for heavy machinery and equipment. It's rigid and cost-effective, perfect for engine blocks, gearboxes, and supports. Its high carbon content also means less maintenance.

Construction and Infrastructure

Steel is better for construction and infrastructure. It's strong and flexible, ideal for beams, columns, and foundations. Steel also comes in many grades for different needs.

Automotive and Transportation Parts

In cars and transport, both cast iron and steel are used. Cast iron is good for engine parts because of its durability and heat handling. Steel is better for frames and parts needing strength and to last long.

Piping and Plumbing

Cast iron is great for pipes and plumbing because it resists corrosion. It's a good choice for harsh environments or corrosive fluids. But, steel is better for high-pressure systems.

The choice between cast iron and steel depends on your project's needs. Knowing each material's strengths helps make the right choice for your project's success.

| Material | Ideal Applications | Key Characteristics |

|---|---|---|

| Cast Iron |

|

|

| Cast Steel |

|

|

Understanding cast iron and cast steel's strengths and limits helps choose the right material for your project. This ensures your project's success and longevity.

Expert Tips for Procuring the Right Material

Choosing the right materials for your project is key. You need to think about more than just strength and hardness. The choice between cast iron and stainless steel affects how well your product works, how easy it is to maintain, and its overall cost.

Checklist for Evaluating Material Needs

- Know what your project needs, like higher carbon content or the ability to handle high temperatures.

- Think about the environment your material will face, including corrosion and wear.

- Consider the manufacturing process. Will the material need extra fabrication steps, like molding or finishing?

- Decide if you need the material to keep certain properties, like thermal conductivity or magnetism, over time.

Case Study: Enhancing Project Efficiency with Expert Guidance

At KT-FOUNDRY, we recently worked with a client in the automotive industry who needed guidance on selecting the right material for engine mounts. They were initially inclined to use cast iron, but after analyzing their project’s requirements, we recommended cast steel for its superior fatigue resistance and strength under repeated stress. This decision helped the client reduce long-term maintenance costs and improve the durability of their components.

The client appreciated our proactive approach and expertise in matching material properties with application needs. This case illustrates the value of consulting with a knowledgeable supplier to make informed, strategic decisions.

Encouragement to Reach Out for Customized Guidance

KT-FOUNDRY is here to provide tailored support for your material selection process. With extensive expertise in cast iron and steel, we can help you identify the best solution for your project. Our team will guide you from material selection through to delivery, ensuring optimal alignment with your project’s requirements.

Whether you need assistance in determining the best material or are looking to customize your order, we’re here to help. Send us an inquiry to discuss how our solutions can support your project goals.