When it comes to material handling systems, the importance of selecting the right chute liners cannot be overstated. At KT Foundry, we’ve spent years refining our expertise in manufacturing high-performance KT-Chute Liners to meet the diverse needs of industries such as mining, cement, aggregates, and steel. Choosing the right chute liner is not just about improving material flow—it’s about enhancing durability, reducing maintenance costs, and ensuring long-term operational efficiency.

In this guide, we’ll walk you through the key factors to consider when selecting chute liners, share insights from our experience, and provide real-world examples to help you make an informed decision.

1. Understand Your Material Handling Requirementsn

The first step in choosing the right chute liner is to thoroughly understand your material handling requirements. Different materials—whether abrasive, corrosive, or high-temperature—pose unique challenges that demand specific liner properties.

For example, in mining applications, materials like iron ore and copper concentrate are highly abrasive and can quickly wear down standard liners. In contrast, industries like steel manufacturing deal with extreme temperatures and heavy impacts. At KT Foundry, we’ve developed specialized KT-Chute Liners tailored to these conditions.

A recent case study with a mining client highlights this perfectly. By analyzing their material flow and abrasion challenges, we recommended our high-abrasion-resistant liners, which increased the chute lifespan by over 200% and significantly reduced downtime.

2. Evaluate Material Options for Chute Liners

Chute liners are made from a variety of materials, each offering distinct advantages depending on the application. Here are some common options:

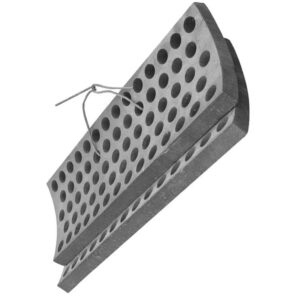

- High-Chromium Iron Liners: Ideal for abrasive materials, these liners offer exceptional wear resistance and durability.

- Ceramic Liners: Perfect for high-impact and high-temperature environments, ceramic liners provide excellent corrosion resistance.

- Rubber Liners: Suitable for applications requiring noise reduction and impact absorption.

At KT Foundry, we specialize in manufacturing high-quality KT-Chute Liners using advanced materials. For instance, our high-chromium iron liners have been successfully deployed in cement plants, where they’ve withstood the abrasive nature of clinker and extended chute life by over 300%.

3. Consider the Design and Installation Processn

The design and installation of chute liners play a crucial role in their performance. A poorly designed liner can lead to material buildup, blockages, and uneven wear, negating its benefits.

Our team at KT Foundry takes a holistic approach to chute liner design. We consider factors such as chute geometry, material flow patterns, and impact zones to create liners that optimize performance. Additionally, our liners are designed for easy installation, minimizing downtime during implementation.

In one case, a steel manufacturing plant faced frequent blockages due to improper chute design. By redesigning the chute and installing our KT-Chute Liners, we eliminated blockages and improved material flow efficiency by 35%.

4. Assess Long-Term Cost and ROI

While the initial cost of chute liners is an important consideration, it’s equally crucial to evaluate their long-term return on investment (ROI). High-quality liners may have a higher upfront cost but can save significant expenses in maintenance, replacements, and downtime over time.

Our KT-Chute Liners are engineered to deliver maximum ROI. For example, in an aggregates processing plant, the installation of our liners reduced maintenance costs by 50% and extended the chute lifespan by over 250%. This not only improved operational efficiency but also provided substantial cost savings.

5. Leverage Expertise and Custom Solutionsn

Every application is unique, and a one-size-fits-all approach rarely works when it comes to chute liners. That’s why partnering with an experienced manufacturer like KT Foundry is essential.

Our team works closely with clients to understand their specific challenges and develop customized solutions. Whether you need liners for extreme temperatures, corrosive materials, or high-impact environments, we have the expertise to deliver.

A recent example involves a cement plant that required liners capable of withstanding temperatures exceeding 800°C. By leveraging our advanced materials and design capabilities, we developed a solution that not only met but exceeded their expectations.

6. Real-World Case Studies: Proven Successn

At KT Foundry, we take pride in our proven track record of delivering high-performance chute liners. Here are two examples of how our KT-Chute Liners have made a difference:

Mining Industry: A copper mining operation was experiencing frequent chute failures due to the abrasive nature of the ore. After installing our high-chromium iron liners, the chute lifespan increased by 200%, and maintenance costs dropped by 40%.

Cement Industry: A cement plant faced constant blockages and wear in their clinker chutes. Our customized ceramic liners eliminated blockages and reduced downtime by 30%, significantly improving productivity.

Conclusionn

Choosing the right chute liners is a critical decision that can have a profound impact on your material handling efficiency, equipment durability, and overall operational costs. At KT Foundry, we’re committed to providing high-quality KT-Chute Liners that deliver optimal performance and long-term value.

By understanding your requirements, evaluating material options, and leveraging our expertise, you can make an informed choice that ensures success. Visit our website to explore our range of chute liners and discover how we can help you achieve your goals.