A mini welding table is key for welding fans or pros. It gives a solid place for welding. Made from heavy steel, these tables can handle welding's tough demands.

They're perfect for small spaces like home workshops or garages. You can pick from different legs and setups to match your needs. This makes it a great pick for welding tables.

We aim to cover the mini welding table's main points. We think it's a must-have for welding lovers or pros. It's built to last with heavy steel and offers many options. We'll dive into these details in the next parts.

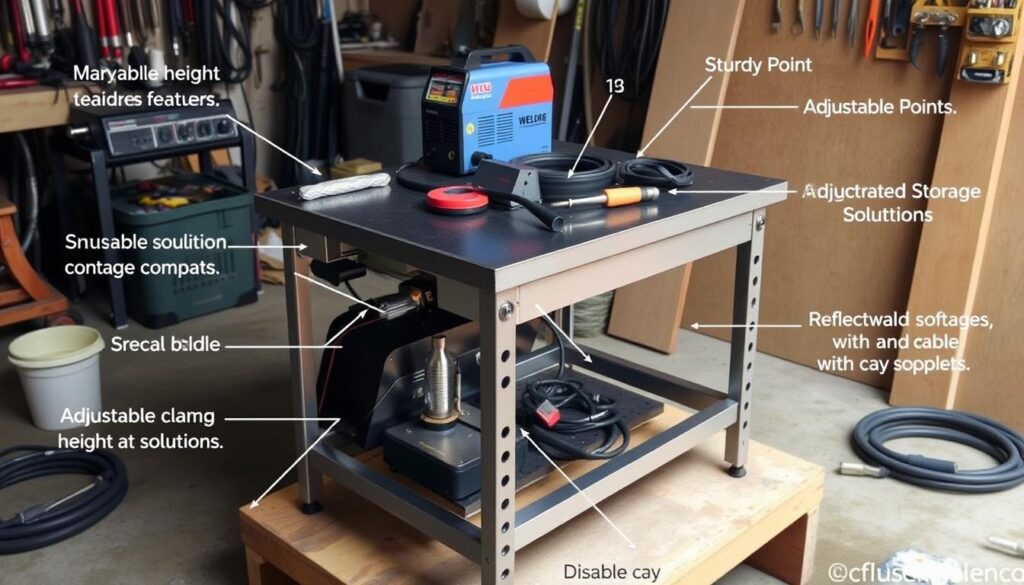

Understanding the Mini Welding Table's Core Features

We aim to give you a detailed look at the mini welding table's main features. We focus on its heavy-duty steel build and how durable it is. The table's construction is key because it must handle the heat and physical stress of welding.

A heavy-duty steel build means the table is tough and lasts a long time. This makes it a smart choice for any workshop.

The size and weight capacity of the mini welding table are also important. These factors decide what projects the table can do. It's crucial to pick a table that fits your needs.

The table's surface has features like slots, studs, and flat areas. These help with fixturing and clamping. This versatility lets you do many different welding tasks.

Key Features of the Mini Welding Table

- Heavy-duty steel construction for enhanced durability

- Size specifications and weight capacity to handle various projects

- Surface features for fixturing and clamping

- Fixturing options for secure and convenient setup

The fixturing options on the mini welding table make setting up projects easy and secure. This boosts your productivity and precision. With its strong steel build, size, and surface features, the mini welding table is perfect for any workshop.

Specifications and Options

| Feature | Specification | Options |

|---|---|---|

| Construction | Heavy-duty steel | Durable, long-lasting |

| Size | Compact, versatile | Various sizes available |

| Weight Capacity | High weight capacity | Handles heavy projects |

Setting Up Your Mini Welding Table

Setting up your mini welding table is key for a safe and efficient welding experience. Many mini welding tables have a modular design for easy assembly and configuration. It's important to follow the manufacturer's instructions to ensure the table is secure and ready for use.

The adjustable height and sturdy base offer stability. Adding casters makes the table easy to move around the workshop. To set up smoothly, consider these steps:

- Unpack and organize all the components and tools provided with your mini welding table

- Assemble the table according to the manufacturer's instructions, ensuring all parts are securely fastened

- Configure the table to your desired setup, taking into account the adjustable height and base requirements

- Test the table to ensure it is level and stable, making any necessary adjustments to the casters or base

By following these steps and considering your welding needs, you can set up your mini welding table safely and efficiently. Always follow the manufacturer's instructions and take safety precautions when using welding equipment.

Versatile Applications and Workspace Solutions

We know how important versatility is in metal fabrication projects. Our mini welding table is made to fit many uses and workspace needs. It's great for cutting, welding, and putting metal parts together, making it a key tool for many tasks.

Our goal is to show how a mini welding table helps in metal fabrication. It's easy to move and fits well into current workflows. Some main benefits include:

- Portability, perfect for welding jobs that need to be done in different places

- Easy to add to your current workflow, becoming a main spot for welding tasks

- Helps save space and makes work flow better in your workshop

For setting up your workshop, place the mini welding table near other important tools. This makes your space more efficient and work flow better. By doing this, you can make your metal fabrication and welding projects run smoother.

The mini welding table is a big help for metal fabrication projects. It gives a stable place for cutting, welding, and putting metal parts together. Its small size and portability are great for many welding jobs, from building to fixing things. Adding the mini welding table to your workshop helps you work smarter and more efficiently on your projects.

| Application | Benefits |

|---|---|

| Metal Fabrication Projects | Provides a solid foundation for cutting, welding, and assembling metal parts |

| Portable Welding Operations | Ideal for welding operations that require moving from one site to another |

| Workshop Integration | Maximizes space efficiency and workflow productivity in the workshop |

Conclusion: Why a Mini Welding Table Is Your Smart Workshop Investment

Investing in a mini welding table is a smart choice for any workshop or garage. These tables are durable and functional, improving the quality and speed of welding projects. Customers often praise their performance, making them a great addition to any workspace.

When looking at this investment, think about the warranties and refund policies. These can give you the confidence to choose the right table. Adding a mini welding table to your workshop opens up new ways to work more efficiently and better serve your customers.

The mini welding table is a great pick for both hobbyists and professionals. It combines convenience, reliability, and top-notch quality. Upgrade your workshop and see how this investment can change the game.