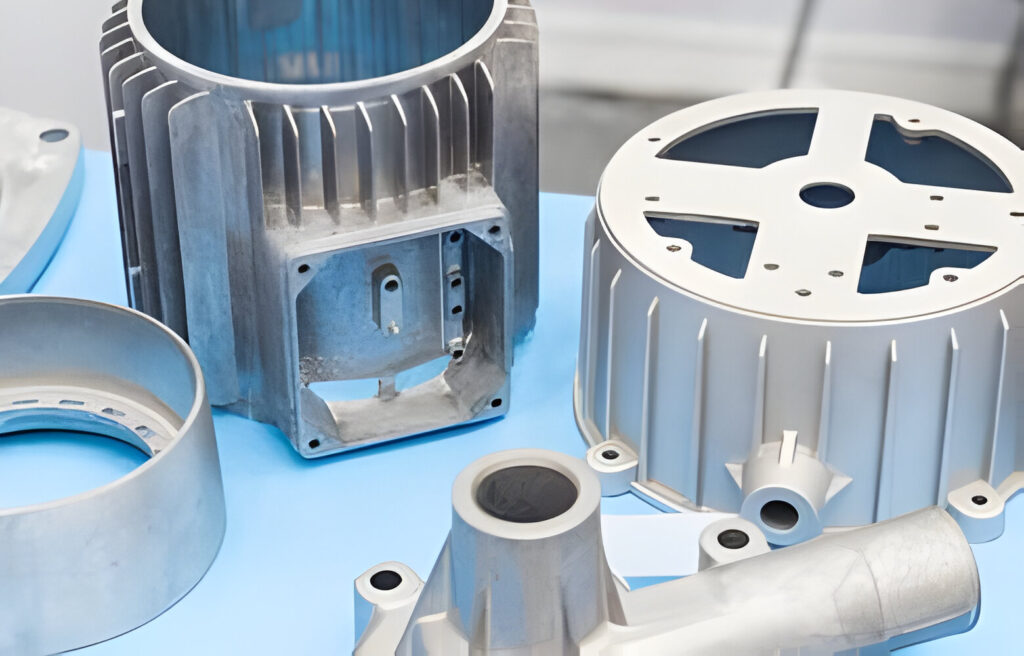

At KT-FOUNDRY, we specialize in custom die casting solutions. We make high-quality, precision-engineered custom die cast parts for many industries. These include automotive, aerospace, electronics, and consumer products.

Our advanced facilities and deep materials knowledge let us create complex, durable metal parts. We meet your exact needs. From the start to the end, we're your go-to for custom die casting excellence.

Key Takeaways

- KT-FOUNDRY provides custom die casting solutions for precision parts

- We specialize in manufacturing high-quality, customized die cast components

- Our expertise covers a wide range of industries, including automotive, aerospace, and electronics

- Our state-of-the-art facilities and materials knowledge enable us to deliver complex, durable parts

- We are your trusted partner for custom die casting excellence, from design to delivery

Introduction to Custom Die Casting

The art of die casting has a long history, starting in the mid-1800s. The first patent for a die-casting machine was filed in the United States back then. Over the years, the process has changed a lot. The 1940s and 1950s saw the introduction of hydraulic and electric machines. These advancements made the process faster and more accurate.

What is Die Casting?

Die casting is a way to make metal parts by forcing molten metal into a mold. This method is mainly used for non-ferrous metals like zinc, aluminum, magnesium, and copper alloys. It's great for making complex and precise parts, which is why it's so popular in many industries.

Benefits of Die Casting

- High dimensional accuracy and repeatability

- Ability to produce complex shapes and intricate designs

- Rapid fabrication of parts with reduced lead times

- Lower production costs compared to other manufacturing methods

- Excellent surface finish and minimal post-processing requirements

The die casting process has many benefits. It's perfect for making complex parts quickly and at a lower cost. This makes it a key part of modern manufacturing.

"Die casting is a versatile and efficient metal casting process that has transformed the way we produce complex and precise metal parts. Its benefits, from high dimensional accuracy to rapid fabrication, make it an invaluable asset in modern manufacturing."

KT-FOUNDRY: Your Die Casting Partner

At KT-FOUNDRY, we lead as a die casting company with custom solutions. Our facilities boast advanced die casting machines. This lets us meet a wide range of metal casting needs. We work with aluminum and zinc and many metal alloys, helping you find the perfect material.

Our Die Casting Capabilities

We're your go-to die casting manufacturer with vast die casting capabilities. Our team uses the latest tech to make parts that meet your high standards. We handle small parts and big, complex ones, making your ideas real.

Materials Expertise

Our knowledge in materials sets us apart at KT-FOUNDRY. We work with aluminum, zinc, magnesium, and some copper alloys. This knowledge helps us find the best material for your project, ensuring it works well, lasts long, and is cost-effective.

"As your die casting partner, we are committed to delivering high-quality, precision-engineered parts that exceed your expectations."

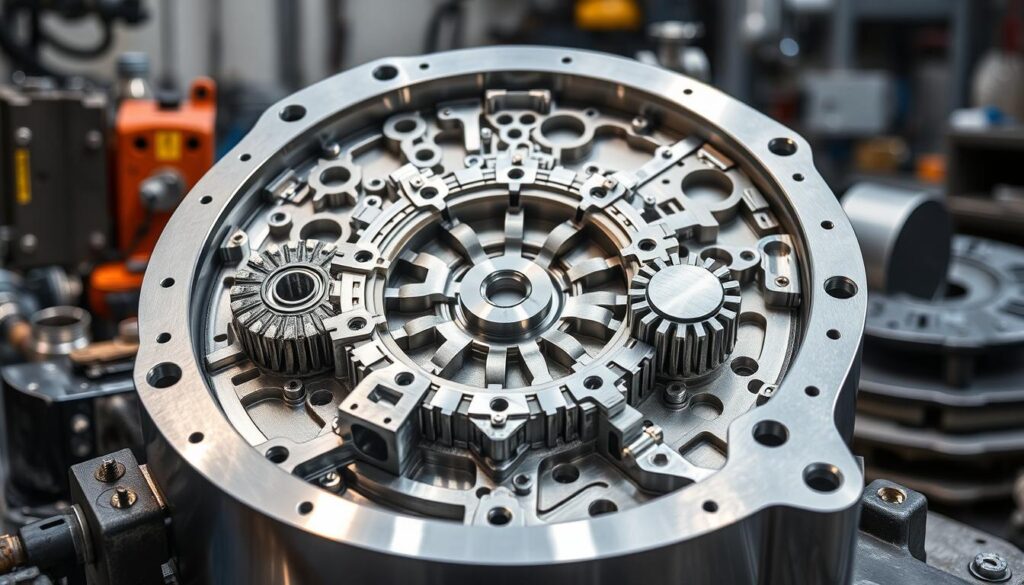

Custom Die Casting Process

At KT-FOUNDRY, we start with detailed die design and engineering. Our team works with you to make part designs better. This means less defects and easier making. We use hot and cold chamber die casting machines for different metals.

The process fills the mold with molten metal under pressure. This makes complex, precise parts possible.

Die Design and Engineering

Our die design and engineering are key to your project's success. We ensure your part design is perfect for making. Our experts in die design and die engineering make sure your parts are top-notch.

Die Casting Machines: Hot and Cold Chamber

KT-FOUNDRY uses hot chamber die casting and cold chamber die casting machines. Our hot chamber machines can handle up to 300 tonnes. Cold chamber machines go up to 900 tonnes.

This lets us make a wide range of parts. From small details to big, complex pieces.

| Die Casting Machine Capabilities | Specifications |

|---|---|

| Hot Chamber Die Casting | Up to 300 Tonne capacity |

| Cold Chamber Die Casting | Up to 900 Tonne capacity |

| Dimensional Tolerances | +/- 0.003" – 0.005" per inch, and even as tight as +/- 0.001" depending on customer specifications |

| Filling Speed | 10-50 meters per second, reaching up to 80 meters per second in some instances |

| Production Time | Typically about 0.01-0.2 seconds for filling the cavity |

Our advanced die casting machines and die fabrication skills mean we can meet your needs. We offer high-quality, custom casting process solutions.

Advantages of Custom Die Casting

Custom die casting brings many benefits to modern manufacturing. It can make parts with complex shapes and thin walls. These parts are very strong and stable, often better than those made by plastic injection molding.

The process ensures parts fit perfectly, thanks to its high precision. Tolerances are as tight as +/-0.003" to 0.005" per inch. This precision is key for parts to work well together.

Die casting also lets you add various finishes. You can choose from smooth or textured surfaces, paints, and plating. These finishes not only look good but also protect against corrosion, making parts last longer.

Lastly, die casting is cost-effective, especially for making lots of parts. It combines precise shapes, strong materials, and customizable finishes. This makes it a top choice for making durable, attractive, and affordable components.

| Advantages of Custom Die Casting | Key Benefits |

|---|---|

| Complex Geometry | Ability to produce parts with challenging features and thin walls |

| Part Strength | Metal die castings are typically stronger than plastic injection molded parts |

| Dimensional Accuracy | Tight tolerances ranging from +/-0.003" to 0.005" per inch |

| Custom Finishes | Wide range of options, including smooth or textured surfaces, paints, and plating |

| Cost-effective Manufacturing | Highly efficient for high-volume production |

In conclusion, custom die casting is a great choice for modern manufacturing. It offers precision, strength, and customization, all at a cost-effective price. This makes it a winning solution for many industries.

Precision and Quality Assurance

At KT-FOUNDRY, we focus on top-notch precision and quality in our custom die casting. We use advanced methods for checking and improving our work. This ensures every product is accurate and consistent.

Rigorous Process Control

We take a detailed approach to controlling our process. We use the latest technology to make our die casting better. Our facilities meet ISO:9001 standards, showing our commitment to quality.

We work with various materials like aluminum and zinc, picked for each project's needs. Our machines are made for different materials, allowing us to make many parts with exact details.

Design for Die Casting (DFD)

We work closely with our clients during the Design for Die Casting (DFD) phase. This helps us make parts efficiently and avoid defects. Our team uses advanced tools to ensure your parts meet high standards.

| Key Quality Assurance Practices | Benefits |

|---|---|

| Dimensional Accuracy | Die castings can have thinner walls compared to other casting methods, and they are generally stronger than plastic injection moldings of the same dimensions. |

| Internal Defect Detection | Technologies like X-ray and ultrasonic inspection are used to detect internal flaws in custom die casting parts. |

| Material Testing | Thorough material testing, including mechanical property analysis and chemical composition verification, is conducted for custom die casting parts. |

| Process Optimization | Simulation tools are utilized to analyze the die casting process and optimize mold designs for enhanced part quality. |

We follow these best practices to ensure your custom die cast parts are top-notch. They meet and exceed industry standards for process control, quality assurance, dimensional accuracy, and quality consistency.

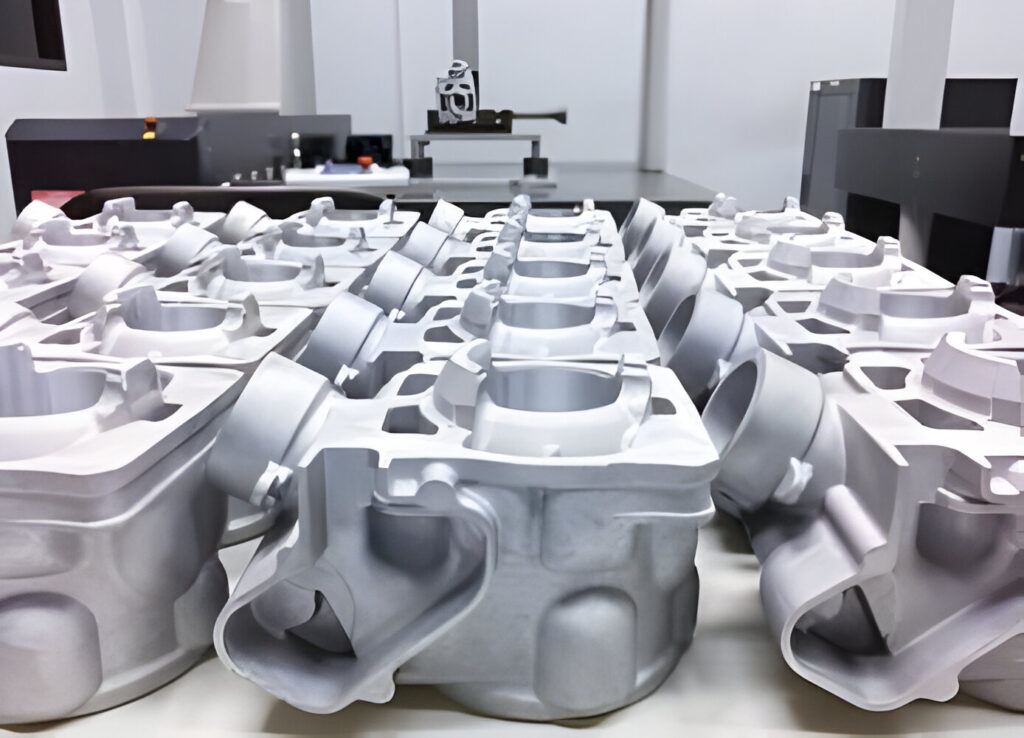

Custom Die Casting Applications

At KT-FOUNDRY, we offer custom die casting solutions for many industries. We focus on automotive, transportation, aerospace, and defense. Our goal is to make complex, high-performance metal parts. These parts need to be strong, reliable, and precise.

Automotive and Transportation

In the automotive and transportation fields, our parts are key. They help powertrains and suspension systems work smoothly. We use automotive die casting and transportation die casting to make parts that are both light and efficient. This helps vehicles run better and use less fuel.

Aerospace and Defense

Aerospace and defense need parts that are precise and reliable. KT-FOUNDRY's custom die casting is perfect for these areas. We make aerospace die casting and defense die casting parts that are strong and light. These parts are crucial in aerospace and defense, ensuring they work well under high pressure.

In all these areas, KT-FOUNDRY's expertise is key. We create complex metal parts and high-performance components that drive innovation. Our focus on quality and customer satisfaction makes us a reliable partner for top manufacturers.

Secondary Operations and Finishing

At KT-FOUNDRY, we know that custom die casting is just the start. We offer a wide range of secondary operations and finishing services. Our team can machine and deburr parts to improve their surface and function. We also plate and paint to make them look better and last longer.

Machining and Deburring

Die casting makes parts very precise, but sometimes more work is needed. Our skilled machinists use advanced CNC machines for this. They make sure the parts are processed perfectly.

We also deburr parts to get rid of extra material or sharp edges. This leaves them smooth and ready for use.

Plating and Painting

We enhance the parts' durability and look with plating and painting. Our plating services include zinc, nickel, and chrome. These improve the parts' resistance to corrosion and their appearance.

Our painting services, like powder coating and wet painting, let you customize the parts further. This makes them look and feel exactly as you want.

KT-FOUNDRY makes sure your die cast parts are ready for use. Our wide range of services means we can meet all your needs. We aim to exceed your expectations with our turnkey solutions.

Custom Die Casting Materials

At [https://kt-foundry.com/innovative-aluminium-die-casting-solutions-for-led-housings-and-motor-enclosures/], we specialize in making precise die cast parts from many non-ferrous metals. We help you pick the best material for your project, considering strength, weight, and more. This ensures your parts work well and last long.

Need custom aluminum die cast parts, zinc die castings, or copper alloy pieces? Our team can make high-quality, custom parts for you. We work with a variety of non-ferrous metals, like:

- Aluminum alloys

- Zinc alloys

- Magnesium

- Select copper alloys

We use advanced die casting machines to make detailed metal parts. Our machines range from 250 to 800 tons. We follow top standards to make sure every part is perfect.

| Material | Minimum Part Weight | Maximum Part Weight | Minimum Part Size | Maximum Part Size | Minimum Wall Thickness | Maximum Wall Thickness |

|---|---|---|---|---|---|---|

| Aluminum Alloy | 0.017 kg | 12 kg | ∅17 mm × 4 mm | 300 mm × 650 mm | 0.8 mm | 12.7 mm |

| Zinc Alloy | 0.017 kg | 12 kg | ∅17 mm × 4 mm | 300 mm × 650 mm | 0.8 mm | 12.7 mm |

| Magnesium Alloy | 0.017 kg | 12 kg | ∅17 mm × 4 mm | 300 mm × 650 mm | 0.8 mm | 12.7 mm |

| Copper Alloy | 0.017 kg | 12 kg | ∅17 mm × 4 mm | 300 mm × 650 mm | 0.8 mm | 12.7 mm |

We're committed to quality, shown by our ISO 9001:2015 certification. You can count on [https://kt-foundry.com/innovative-aluminium-die-casting-solutions-for-led-housings-and-motor-enclosures/]KT-FOUNDRY for top-notch die casting solutions, no matter your industry.

FAQ

What is die casting and how does it work?

Die casting is a manufacturing process that involves forcing molten metal into a mold cavity. The process is highly efficient and is primarily used for producing parts with complex shapes and fine details. In die casting, a die casting machine is used, which can be classified into two main types: hot chamber die casting and cold chamber die casting. The chosen method depends on the type of metal being cast, with aluminum and zinc being popular choices. The die casting process results in high precision and smooth surface finishes, making it ideal for various applications.

What are the advantages of using custom die casting services?

Using custom die casting services offers several advantages, including enhanced design flexibility, improved production efficiency, and superior quality control. With custom die cast parts, manufacturers can create highly intricate designs that meet specific requirements. Additionally, die casting allows for the production of large volumes of parts with consistent quality, which is crucial for mass production. The die casting manufacturing process also minimizes waste, making it a cost-effective solution for producing metal parts.

What types of die casting materials are commonly used?

Common die casting materials include aluminum, zinc, and magnesium. Among these, aluminum alloys are particularly popular due to their excellent mechanical properties and resistance to corrosion. Zinc alloy is also favored for its low melting point and ease of casting, making it suitable for producing small, intricate parts. The choice of die casting materials depends on the application's requirements, such as strength, weight, and thermal conductivity.

How do I choose the right die casting company for my project?

When selecting a die casting company, consider factors such as experience, technical capabilities, and quality certifications. A reputable <

Conclusion

At KT-FOUNDRY, we're all about giving our clients top-notch custom die casting solutions. Our facilities are cutting-edge, and our team is skilled in advanced manufacturing. We make parts that fit your exact needs.

We work hand in hand with you, from the start to the finish. This way, we make sure your parts are just what you want. We're your go-to partner for all things custom die casting.

We use materials like aluminum, magnesium, and zinc to make parts that are smooth and precise. Our parts meet your exact weight and tolerance needs. This means you get parts that are perfect for cars or complex industrial designs, saving you time and money.

Ready to see how we can help? Contact us today. Let KT-FOUNDRY be your partner in precision engineering and quality parts. We'll help take your products to the next level.