When it comes to precision and efficiency in welding projects, the choice of the right welding table is crucial. Among the various options available, the slotted welding table top stands out for its versatility and functionality. This article explores the features, benefits, and practical applications of slotted welding tables and other related products, helping you make an informed decision for your welding needs.

The Unique Advantages of Slotted Welding Table Tops

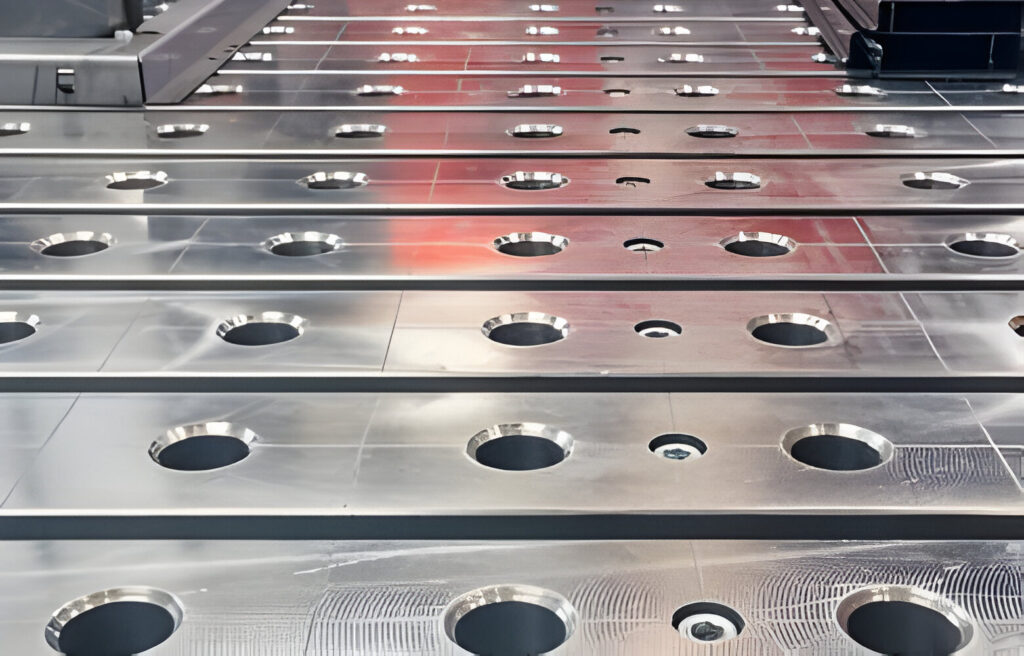

A slotted welding table top is designed with a series of slots that allow for easy clamping and positioning of workpieces. These slots provide multiple points of adjustment, making it easier to secure and manipulate materials during welding. This feature is particularly beneficial for complex projects requiring precision and stability.

Product Highlights

- Slot and Tab Welding Table: Combining the advantages of slotted designs with the stability of tab and slot constructions, these tables are perfect for heavy-duty welding tasks. The tabs ensure a robust assembly, while the slots offer flexibility in clamping.

- C Channel Welding Table: Featuring a C-channel design, these tables provide additional strength and support. The channels can be used to mount various fixtures and accessories, enhancing the table’s functionality.

- T Slot Welding Table: Similar to slotted tables, T slot welding tables offer a grid of T-slots that allow for the secure attachment of clamps and tools. This design is ideal for repetitive tasks where consistent positioning is required.

- Welding Table Tab and Slot: This design incorporates tabs and slots for quick assembly and disassembly, making it easy to transport and store. It's perfect for mobile welding units or small workshops with limited space.

- Sink Welded into Table Top: For specialized applications, some welding tables feature a sink welded directly into the table top. This is useful for projects that generate significant debris or require cooling of parts during the welding process.

Practical Applications

Slotted welding tables are indispensable in various industries, including automotive, aerospace, and metal fabrication. Their ability to hold irregularly shaped workpieces securely makes them ideal for custom fabrication tasks. The adjustable clamping points also facilitate complex welds and assemblies, reducing the need for additional jigs and fixtures.

For instance, in automotive manufacturing, a slotted welding table can hold car frames and body parts in place, ensuring precision and reducing the time required for alignment. In aerospace, the flexibility of slot and tab welding tables allows for the precise welding of components that demand high accuracy.

Why Choose a Slotted Welding Table Top?

The adaptability of a slotted welding table top makes it a valuable investment for any workshop. The slots provide unparalleled flexibility in clamping and positioning, which is essential for achieving high-quality welds. Moreover, the durability and robustness of these tables ensure they can withstand the rigors of daily use in demanding environments.

Whether you are a professional welder or a hobbyist, a slotted welding table top can significantly enhance your productivity and accuracy. By choosing the right table, you can ensure that your welding projects are completed efficiently and to the highest standards.

Contact Us

At KT-Foundry, we offer a wide range of welding tables, including slotted welding table tops, C channel welding tables, and more. Our products are designed to meet the needs of various welding applications, ensuring you have the right tools for the job. Visit our website (kt-foundry) to explore our product offerings and contact us for more information or to place an order.