In the realm of fluid management, the reliability and longevity of equipment are paramount. Whether for agricultural, industrial, or domestic use, the efficiency of pumps directly impacts productivity and convenience. Among the plethora of materials available for pump construction, cast iron stands out for its exceptional durability and resilience. Within this domain, cast iron pump parts play a pivotal role in ensuring the smooth operation and longevity of various pumping systems.

The Legacy of Cast Iron Pump Parts

From antique hand water pump parts to modern submersible pump casting parts, cast iron has been a staple material in pump manufacturing for centuries. Its remarkable properties make it an ideal choice for constructing pump components that withstand harsh environments and heavy usage.

Versatility and Strength

Cast iron pump parts exhibit remarkable versatility and strength, making them suitable for diverse applications. Whether it's a deep well hand pump, a pitcher pump, or a submersible pump, cast iron components offer the robustness required to handle the rigors of pumping operations. These parts are resistant to corrosion, abrasion, and chemical damage, ensuring prolonged service life even in demanding conditions.

Precision Engineering for Optimal Performance

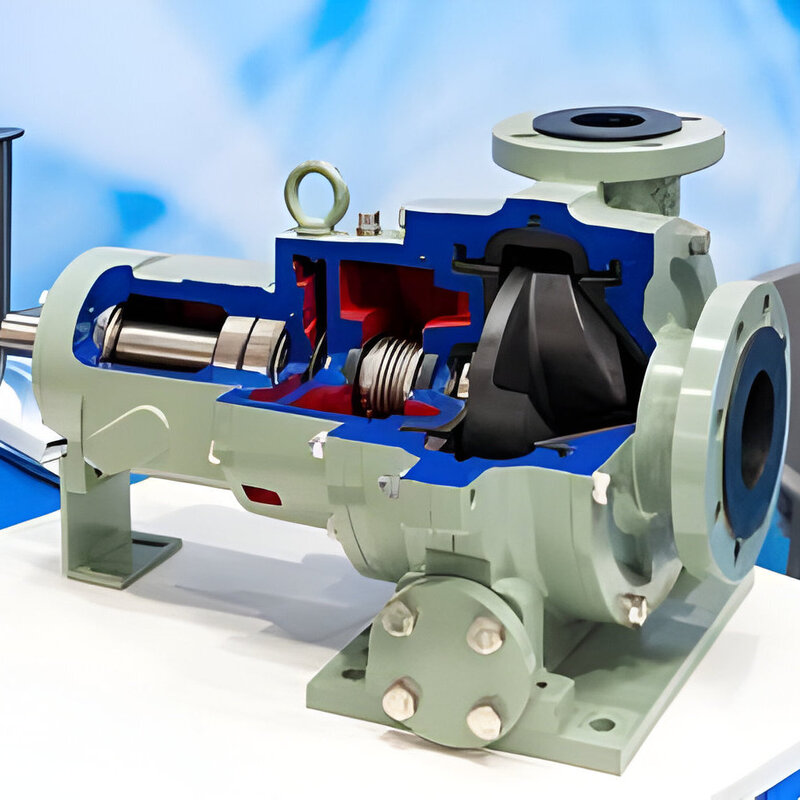

Manufacturers of cast iron pump parts employ advanced casting techniques to ensure precision engineering and consistent quality. From casting slurry pump parts to intricate submersible pump components, every piece undergoes meticulous craftsmanship to meet stringent standards. This attention to detail translates into enhanced performance, minimal downtime, and reduced maintenance costs for end-users.

Exploring the Range of Cast Iron Pump Parts

The repertoire of cast iron pump parts is extensive, catering to various types of pumping systems and applications. Among these, antique hand water pump parts evoke nostalgia while showcasing the enduring reliability of cast iron. Similarly, cast iron hand pump parts retain their charm and functionality, serving as testament to the timeless appeal of this material in fluid management.

Pitcher pumps, characterized by their simplicity and effectiveness, rely on cast iron pump parts for their base, housing, and internal components. A pitcher pump rebuild kit, comprising carefully crafted cast iron parts, rejuvenates aging pumps, restoring them to optimal performance.

Meeting Industry Standards with Pump Castings

In industrial settings, where efficiency and durability are paramount, pump castings play a crucial role in maintaining operations. Whether it's for slurry pumps used in mining or dredge pumps deployed in marine applications, cast iron pump castings offer unparalleled strength and resilience. Manufacturers leverage advanced casting technologies to produce intricate parts with complex geometries, ensuring compatibility with various pump designs and specifications.

Partnering with Pump Casting Manufacturers

For businesses seeking reliable pump components, forging partnerships with reputable pump casting manufacturers is imperative. These manufacturers not only offer a wide range of cast iron pump parts but also provide customization options to meet specific requirements. Whether it's adapting parts for unique pump designs or optimizing materials for enhanced performance, collaborating with experts in pump casting ensures seamless integration and long-term reliability.

Conclusion

Cast iron pump parts epitomize durability, reliability, and versatility in fluid management applications. From antique hand water pump parts to modern submersible pump casting components, the legacy of cast iron in pumping technology endures. By investing in quality cast iron pump parts and partnering with trusted manufacturers, businesses can optimize efficiency, minimize downtime, and maximize productivity in their pumping operations.