In the realm of industrial machinery, particularly in sectors like mining, construction, and wastewater treatment, the efficiency and reliability of equipment are paramount. One crucial component within these systems is the slurry pump, tasked with transporting abrasive fluids with high solid content. To ensure optimal performance and longevity, utilizing OEM slurry pump casting parts becomes indispensable.

Cast iron has long been revered for its robustness and durability, making it a prime choice for manufacturing pump components. Within the spectrum of cast iron pump parts, OEM options stand out for their precision engineering and compatibility with specific pump models. These parts, meticulously crafted to OEM specifications, offer a seamless fit and function within existing systems, minimizing downtime and maximizing productivity.

China's prowess in casting technology has made it a hub for manufacturing high-quality pump components. Through advanced casting processes, including investment casting and sand casting, manufacturers can produce intricate parts with exceptional dimensional accuracy. This ensures that each component meets stringent quality standards, crucial for the demanding environments in which slurry pumps operate.

When it comes to slurry pump parts, versatility is key. From antique hand water pump parts to modern submersible pump components, OEM casting covers a vast array of products. Whether it's a deep well hand pump or a pitcher pump rebuild kit, OEM casting ensures that each part maintains the integrity and performance necessary for efficient operation.

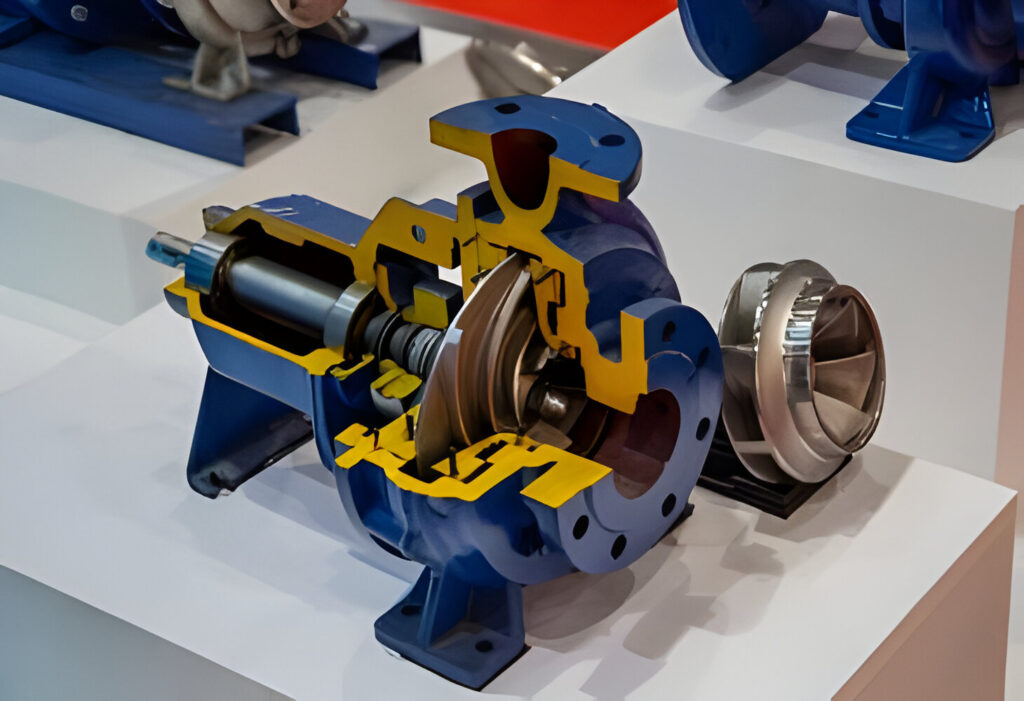

Furthermore, OEM casting extends beyond individual components to encompass entire pump assemblies. Pump casting manufacturers leverage their expertise to produce complete pump units tailored to specific applications. This holistic approach not only simplifies installation but also guarantees optimal compatibility and performance across the entire system.

In industries where downtime can translate to significant losses, spare parts availability is critical. OEM casting addresses this need by offering a comprehensive range of pump spare parts readily accessible to customers. Whether it's a replacement impeller for a slurry pump or a pitcher pump base for a water well system, OEM casting ensures swift turnaround times, keeping operations running smoothly.

Apart from enhancing performance and reliability, OEM slurry pump casting parts also contribute to cost-effectiveness. By leveraging economies of scale and efficient manufacturing processes, OEM options provide competitive pricing without compromising on quality. This makes them an attractive choice for businesses looking to optimize their operational efficiency while staying within budget constraints.

In conclusion, OEM slurry pump casting parts represent the pinnacle of quality, reliability, and performance in industrial pump applications. From cast iron hand water pump parts to cutting-edge submersible pump components, OEM options offer unmatched durability and precision engineering. By investing in OEM casting, businesses can ensure seamless operations, minimize downtime, and maximize profitability.