In the realm of fluid dynamics and machinery, impellers play a pivotal role in various applications, from fuel pumps to centrifugal pumps, and beyond. For industries requiring precision, durability, and efficiency, the choice of impeller casting is crucial. This article delves into the realm of impeller casting manufacturers, exploring their processes, products, and the significance they hold in diverse sectors.

Impeller Casting: Precision Engineering at Its Finest

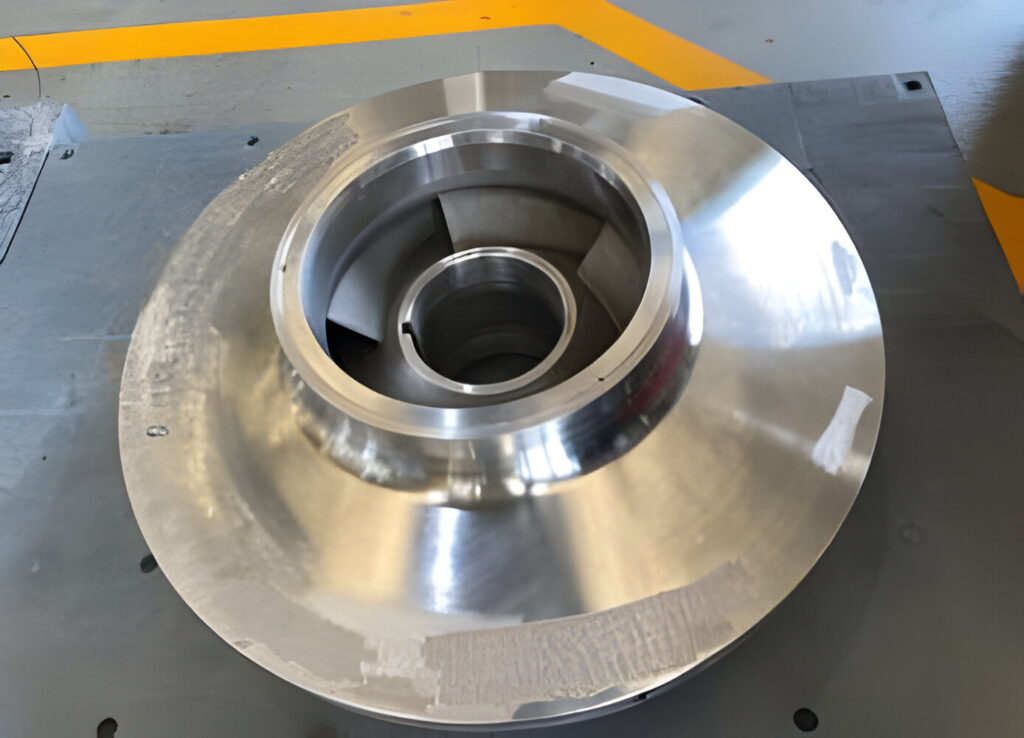

Impeller casting is a specialized process that involves creating intricate, precisely shaped impellers for pumps and other machinery. Among the different techniques utilized, investment casting stands out for its ability to produce complex shapes with high accuracy. This method is particularly favored for crafting impellers used in critical applications such as aerospace, automotive, and marine industries.

Fuel Pump Impellers: Powering Performance

In the automotive sector, fuel pump impellers are indispensable components responsible for delivering fuel to the engine efficiently. Manufacturers specializing in stainless steel casting processes excel in producing fuel pump impellers that meet stringent quality standards. These impellers ensure optimal fuel flow, contributing to the overall performance and fuel efficiency of vehicles.

Centrifugal Pump Impellers: Driving Fluid Dynamics

Centrifugal pumps rely on precisely engineered impellers to convert mechanical energy into fluid flow. Stainless steel impeller casting manufacturers play a crucial role in supplying these components to industries ranging from agriculture to wastewater treatment. The superior corrosion resistance and durability of stainless steel impellers make them ideal for harsh operating environments, ensuring reliable pump performance over extended periods.

Boat Water Pump Impeller: Navigating the Seas Safely

For marine applications, boat water pump impellers are essential for cooling engines and maintaining optimal operating temperatures. OEM well-casted impellers, crafted with precision through investment casting processes, offer marine enthusiasts peace of mind during their voyages. These impellers, often made from bronze or stainless steel, withstand the corrosive effects of saltwater, ensuring longevity and reliability even in challenging maritime conditions.

Pool Pump Impeller: Keeping Recreation Crystal Clear

In the realm of recreational facilities, pool pump impellers play a vital role in circulating water and maintaining water quality. Manufacturers specializing in sand casting processes produce pool pump impellers that combine efficiency with cost-effectiveness. These impellers, typically made from cast iron or stainless steel, ensure smooth operation and optimal filtration, contributing to a clean and safe swimming environment.

Impeller Casting Manufacturers: Meeting Diverse Needs

Impeller casting manufacturers cater to a wide range of industries and applications, offering a plethora of impeller types tailored to specific requirements. Whether it's a cast iron pump impeller for industrial processes or a stainless steel impeller for sanitary applications, manufacturers leverage advanced casting techniques to deliver precision-engineered solutions.

At KT Foundry, we specialize in stainless steel casting processes, producing high-quality impellers for various applications. Our commitment to precision, quality, and customer satisfaction sets us apart in the realm of impeller casting manufacturers. Contact us today to explore our range of products and discover how we can meet your impeller casting needs.