Pump impellers are the heart of pumping systems, responsible for generating the necessary force to move fluids efficiently. The casting process used to manufacture impellers plays a crucial role in determining their performance, durability, and overall quality. In this article, we'll explore the significance of impeller casting, focusing on techniques like investment casting and the advantages of materials such as stainless steel.

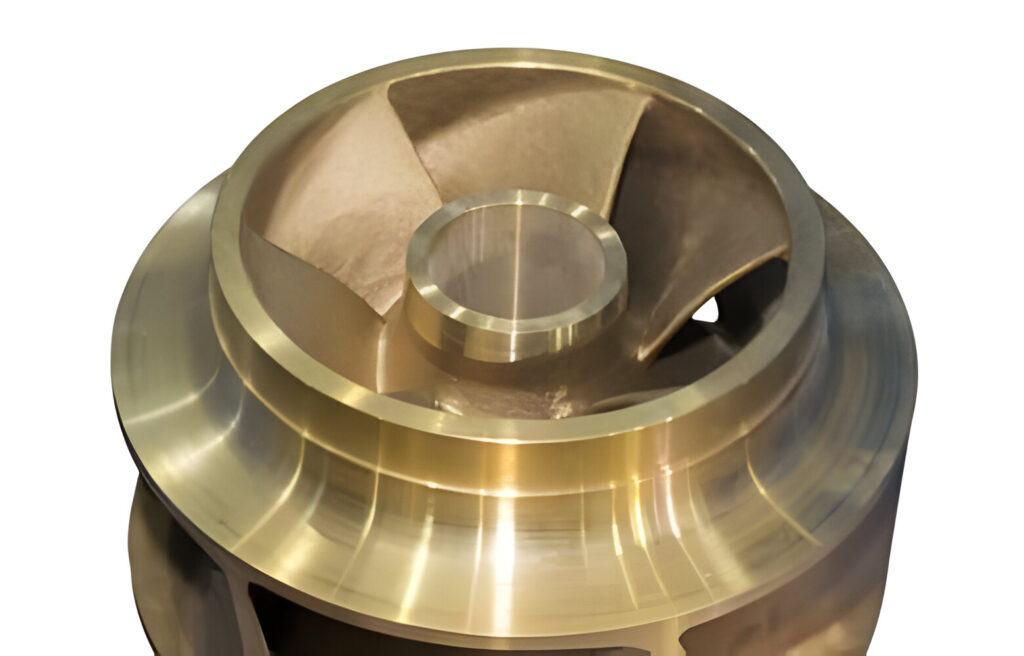

Investment casting is a highly precise method utilized in the manufacturing of pump impellers. This process involves creating a wax pattern of the impeller's design, which is then coated with a refractory material to form a mold. The wax is melted away, leaving behind a cavity that is filled with molten metal, typically stainless steel or other alloys. This intricate process results in impellers with complex geometries, smooth surfaces, and precise dimensions, making them ideal for centrifugal pump impellers and other high-performance applications.

Stainless steel impeller casting offers several advantages over other materials. Stainless steel is known for its excellent corrosion resistance, making it suitable for applications where pumps are exposed to corrosive fluids or environments. Additionally, stainless steel impellers exhibit high strength and durability, ensuring long-term reliability and minimal maintenance requirements. Manufacturers specializing in stainless steel castings can produce impellers tailored to specific requirements, meeting the diverse needs of industries ranging from marine to industrial processing.

Fuel pump impellers are critical components in automotive and aerospace systems, where reliability and efficiency are paramount. Investment casting ensures the production of fuel pump impellers with precise blade profiles and smooth surfaces, minimizing fluid turbulence and maximizing pump efficiency. Stainless steel impeller casting further enhances the durability of fuel pump impellers, ensuring optimal performance under demanding conditions.

Centrifugal pump impellers are widely used in various industries for fluid transportation and processing. Whether for water circulation in pool pumps or OEM well-casted impellers for industrial applications, the casting process directly impacts the performance and longevity of centrifugal pump systems. Stainless steel impeller casting is particularly beneficial in corrosive environments, offering resistance to rust and erosion, thus extending the service life of the pump.

In marine applications, such as boat water pump impellers, the choice between stainless steel and other materials like bronze or cast iron depends on factors such as saltwater exposure, durability, and cost-effectiveness. Stainless steel impellers excel in marine environments due to their corrosion resistance and longevity, ensuring reliable performance even in harsh conditions.

In conclusion, precision impeller casting techniques, particularly investment casting with stainless steel, are instrumental in enhancing pump efficiency, reliability, and durability. Manufacturers specializing in impeller casting can provide tailored solutions to meet the specific needs of diverse industries, from automotive to marine. For premium-quality impellers that optimize pump performance, contact us at KT-Foundry and explore our range of precision casting services.