Steel casting has been around since the early 1900s. It's still key for modern makers in many fields. Choosing the right supplier is vital for top-notch products and timely delivery.

At KT-FOUNDRY, we create custom stainless steel castings with fine details and exact sizes. Our deep experience helps guide clients from design to delivery.

When picking a steel casting supplier, look at mold making, machining, and testing. These aspects greatly affect quality and cost. Our foundry excels in making complex shapes and controlling shrinkage, serving many industries.

It's also important to find a supplier with industry-specific knowledge. For fields like arms or aviation, strict standards and special skills are needed. Working with a foundry that gets your industry's needs ensures your project is done right and fast.

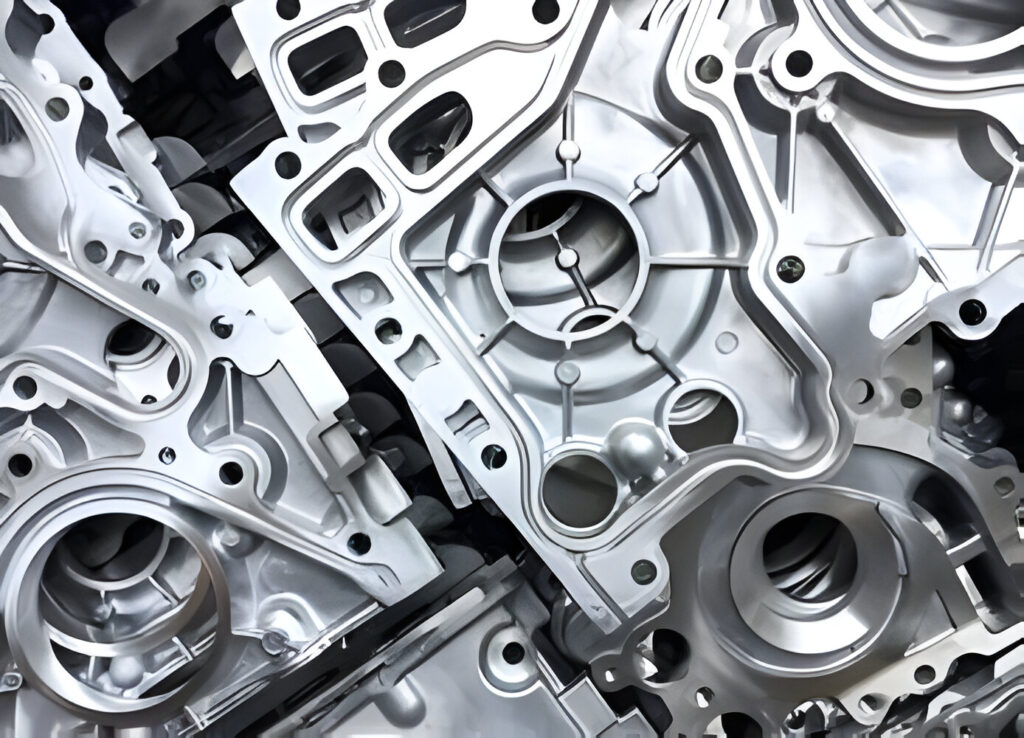

Understanding Steel Casting Processes and Applications

Steel castings are cost-effective and recyclable. They are also of high quality and faster to make than other materials. These materials are used in many industries, from making medical prototypes to parts for cars and planes.

Different Types of Steel Casting Methods

The steel casting industry uses many techniques to make parts. Some common methods are:

- Investment casting, good for small, light parts up to 150 lbs.

- Sand casting, can make parts of any size.

- Permanent mold casting, makes parts with precise metal and shape.

- Centrifugal casting, creates strong, seamless parts like tubes and rings.

Each method has its own benefits, fitting different needs and industries.

Common Applications Across Industries

Steel castings are used in many fields, like electronics, food processing, construction, and aerospace. They are strong, tough, and wear-resistant. This makes them great for parts that need to last under stress and wear.

Material Options and Specifications

Steel castings come in many grades and types, such as carbon steels, alloy steels, stainless steels, duplex stainless, and nickel-based steels. The right material depends on the industry and the casting method used.

"Sujan Industries, a leading stainless steel casting manufacturer in India, is known for its cost-effective, reliable, and efficient casting processes, delivering high-quality products to the market."

Key Factors in Selecting Steel Casting Suppliers

When looking for the best steel casting suppliers, consider several key factors. A good supplier can make your production process smoother. They can also help you save time and money while ensuring high-quality results.

First, find suppliers with strong in-house capabilities. They should handle everything from mold making to machining and testing. Their quality control process should give you confidence in your castings. Also, look for suppliers with industry-specific knowledge to help with design and cost savings.

It's also important to find suppliers who can combine multiple parts into one. This can save you time and money. Make sure they offer the right surface treatments to meet your needs.

| Key Factors | Importance |

|---|---|

| In-house Capabilities | Streamlined production, reduced lead time |

| Industry Experience | Valuable insights for design and cost optimization |

| Cost-effectiveness | Competitive pricing and value-added services |

| Quality Control | Rigorous testing and inspection processes |

| Single Unit Assembly | Reduced assembly time and production costs |

By looking at these factors, you can find a supplier that meets your needs. They should offer great value and make your manufacturing process smooth and efficient.

"Selecting the right steel casting supplier can make all the difference in the success of your custom projects."

Essential Certifications and Quality Standards

Choosing the right steel casting supplier is key for your custom projects. They must meet industry-recognized certifications and quality standards. These show their commitment to excellence and ensure the materials and processes meet your needs.

Industry-Specific Certifications

- ISO 9001 certification for steel industry standard recognized internationally, management system applying to manufacture of steel and alloy-steel castings

- Compliance with Pressure Equipment Directive in casting and welding processes for EU standards

- PED welding accreditation for ASTM A216 WCB/SA-216 WCB and ASTM CF8M/SA-351 CF8M alloys

- ASME compliance for codes administered by American Society of Mechanical Engineers

- AIS compliance for domestic water projects subject to EPA regulations

Testing and Inspection Protocols

Good steel casting suppliers have strong testing and inspection protocols. These ensure the quality and integrity of their products. They include:

- Visual and dimensional inspections

- Microstructure analysis

- Chemical composition analysis

- Non-destructive testing methods such as ultrasonic, radiographic, liquid penetrant, and magnetic particle testing

Material Quality Standards

The materials used should follow industry-recognized standards, like those from ASTM and NACE. This ensures the products are consistent, strong, and resistant to corrosion. It makes sure they fit your specific needs.

Working with a supplier that has these certifications and standards means you can trust your custom components. They will perform well, no matter the industry or use.

Evaluating Custom Manufacturing Capabilities

When looking for the best steel casting suppliers, it's key to check their manufacturing skills. You should look at things like production size, tooling needs, and how complex the designs are. Precision machining and surface finish are also important.

Choose suppliers who are good at making castings with complex shapes, tight tolerances, and superior surface finish. Make sure they offer machining, heat treatment, and sub-assembly services too.

It's important to see if they know how to work with different alloys. They should also meet industry standards and compliance requirements. This ensures your project is done with the highest quality and precision.

| Capability | Importance |

|---|---|

| Production run size | Determines economies of scale and cost-effectiveness |

| Tooling requirements | Impacts lead times and overall project costs |

| Design complexity | Highlights the supplier's ability to handle custom requirements and casting design |

| Precision machining | Ensures tight tolerances and surface finish specifications |

By carefully checking a supplier's custom manufacturing skills, you can find the perfect partner. They will help make your complex shapes and precision requirements a reality. This ensures your custom casting project is a success and done efficiently.

Conclusion

Finding the right reliable steel casting suppliers is key for any custom project. KT-FOUNDRY provides top-notch solutions from start to finish. They ensure high-quality components with precision engineering and competitive pricing.

When choosing a supplier, look at their manufacturing skills, certifications, and experience. This helps find a dependable partner for steel casting needs. Working with KT-FOUNDRY can lead to cost-effective, high-quality results for many industries.

The steel casting field is always changing, with new challenges and chances. Keeping up with modern methods and tech is important. This way, companies can stay competitive and meet the demand for high-quality steel casting components.

Investing in reliable steel casting suppliers like KT-FOUNDRY helps achieve custom project goals. They offer expertise and leading capabilities. This makes them a trusted partner for precision engineering and competitive pricing.

As the industry grows, KT-FOUNDRY stands out as a trusted partner. They focus on high-quality components that meet specific needs. By using the latest advancements and focusing on quality, KT-FOUNDRY is ready to support the evolving needs of steel casting industries.