Gate valves are key in many industries for controlling liquid or gas flow. Knowing the parts of a gate valve is crucial for upkeep and performance. Gate valve castings are made by pouring molten metal into a mold to shape the valve parts.

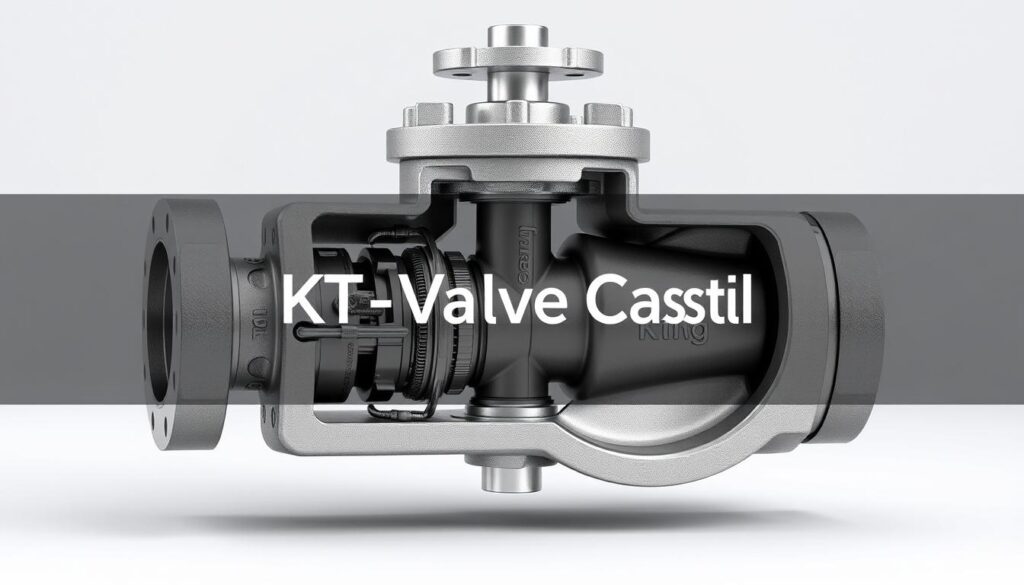

Valve castings are vital for managing fluid, gas, or steam flow. KT-FOUNDRY excels in creating top-notch gate valve castings. They use advanced methods to cater to different industry needs.

Key Takeaways

- Gate valves are essential for controlling fluid flow in pipelines across various industries, including energy, water treatment, manufacturing, HVAC, and marine sectors.

- Casting is a cost-effective method for manufacturing gate valves, offering high strength, durability, and customization capabilities.

- Cast gate valves are known for their excellent corrosion and wear resistance, making them suitable for harsh operating environments.

- Stringent testing procedures, such as hydrostatic, visual, dimensional, and material testing, ensure the quality and adherence to industry standards.

- KT-FOUNDRY is a prominent supplier of high-quality cast gate valves made from durable materials like stainless steel.

Understanding Gate Valves and Their Functionality

Gate valves are key in many industrial places. They control the flow of fluids, liquids, or gases in pipelines. These valves work by using a flat piece that moves in and out of the flow's path. This lets them stop or start the flow easily.

The Gatekeeper of Fluid Flow Control

A gate valve's design is simple yet effective. It has a moving barrier inside the valve body. This design helps gate valves handle high pressures well. They are often used in oil and gas, water treatment, and power generation.

Gate Valve Design Essentials

- The materials used, like cast iron, brass, bronze, or stainless steel, depend on the system's needs. This includes pressure, temperature, and how well it resists corrosion.

- Every part of a gate valve, including the body, bonnet, stem, seat, and seals, is important. They all help the valve work well and last long.

- Gate valves can have different features. For example, they might have rising or non-rising stems. They can also have various actuators, like manual hand-wheels or powered systems. This makes them fit different needs.

Knowing how gate valves work and what they need helps industries pick the right ones. This ensures they can control fluid flow well and work efficiently.

The Versatile Applications of Gate Valve Castings

Gate valve castings are used in many industries. They are key in controlling fluid flow. This is important in places like water treatment and energy production.

Water Treatment Facilities

In water treatment, gate valves control water flow. They help manage water during treatment. This ensures clean, safe water for everyone.

Energy and Power Generation

Gate valves are vital in energy and power. They manage oil, gas, and other resources in pipelines. They can handle high pressure and corrosive materials.

They are also used in food, beverage, pharmaceutical, and automotive industries. These valves control liquids and gases. They help keep production safe and efficient.

In HVAC systems, they manage heating and cooling fluids. This keeps environments comfortable.

The marine industry uses gate valves for seawater management and fire protection. Agriculture uses them in irrigation. This helps water reach crops efficiently.

In summary, gate valve castings are used in many fields. They are essential for fluid flow control. This ensures safety, efficiency, and sustainability in various industries.

Selecting the Right Materials for Gate Valve Casting

Choosing the right materials for gate valve castings is key to their performance and life span. The pressure rating, temperature range, and the type of media being handled are important. At [https://kt-foundry.com/valve-body-casting/], we offer a variety of gate valve casting options. Each is made from materials chosen for their unique needs in different industries.

Materials like cast iron, stainless steel, brass, bronze, carbon steel, alloy steel, nickel-chromium alloy, chromium-molybdenum steel, cast copper, and titanium alloy are used. Each has its own strengths in corrosion resistance, temperature and pressure, and chemical environments.

Cast iron is a cost-effective choice for low to medium pressure. Stainless steel, alloy steel, and nickel-chromium alloy are better for high-pressure and high-temperature. Brass and bronze are good for water systems because of their corrosion resistance. Titanium alloy is best for very corrosive media and seawater.

| Material | Pressure Rating | Temperature Range | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Cast Iron | Low to Medium | -20°C to 450°C | Moderate | Water, Steam, Gas |

| Stainless Steel | High | -40°C to 650°C | Excellent | Corrosive Chemicals, High-Pressure Fluids |

| Brass | Low | -20°C to 150°C | Good | Water, Potable Fluids |

| Bronze | Medium | -20°C to 300°C | Excellent | Seawater, Marine Applications |

By picking the right material, we make sure our gate valve castings are reliable, long-lasting, and fit the needs of our clients. This is true for many industries, from water treatment to energy and power generation.

"Choosing the right materials is key to making high-performance gate valves. Our team's knowledge in material science and casting technology helps our clients get the best solution for their needs."

Forging vs gate valve casting

Choosing between forging and casting for gate valves has its pros and cons. Forging is great for strong and durable valves, perfect for high-pressure and heat. Casting, however, is better for big production runs and offers design flexibility.

Comparing Manufacturing Processes

Sand casting is common for steel valves, especially big ones. Investment casting is better for small, precise parts and is cheaper than sand casting. It can make parts up to 100 kg and 1.6m long.

Forged valves are stronger than cast ones. Forging also gets rid of air pockets, making them last longer. But, forging is pricier and only works for small batches.

Advantages of Gate Valve Casting

Cast valves fit many sizes and shapes, offering design freedom. They're also cheaper to make, with lower labor costs and big batch sizes. Plus, they're quicker to produce.

Cast valves can have a smooth finish, just like forged ones. This makes them a good, affordable choice for many uses.

Deciding between forged and cast valves depends on what you need. It's about balancing cost, performance, and design.

The Investment Casting Process for Gate Valves

At KT-FOUNDRY, we use investment casting to make high-quality gate valves. This method is great for valves because it offers many benefits. It lets us create detailed and complex designs accurately.

The investment casting method, also known as lost-wax, has been around for over 5,500 years. It's good for making small to medium batches of parts. The mold is made of ceramic and is used 6-8 times to create a strong shell. Then, the wax is removed under high pressure and steam to leave an empty mold.

Design Flexibility and Surface Finish Quality

This process gives us a smooth finish, which means less work after casting. It also helps ensure a tight seal. Plus, it works with many materials, like stainless steel and alloys, so we can pick the best one for each job.

The steps include making a pattern, preparing the mold, injecting wax, building a shell, removing wax, pouring metal, cooling, and finishing. This way, we make strong and reliable gate valves. It's a flexible method that gives us great results.

| Investment Casting Advantages | Metrics |

|---|---|

| Design Flexibility | Ability to create intricate and complex valve designs |

| Surface Finish Quality | Smooth surface finish, reducing post-processing requirements |

| Material Selection | Wide range of materials, including stainless steel, carbon steel, alloys, and exotic metals |

| Cost-Effectiveness | Suitable for small to medium production runs, minimizing material waste and machining |

"Investment casting can reproduce millions of wax parts over a mold's lifetime, making it a cost-effective solution for small to medium production runs."

Industries Relying on Gate Valve Castings

Gate valve castings are key components in many industries. They help control flow and manage operations in various sectors. These castings are vital in the oil and gas, chemical, power generation, water treatment, manufacturing, HVAC, marine, fire protection, and agricultural fields.

In the oil and gas industry, these castings control the flow and pressure of crude oil, natural gas, and refined products. They work under extreme conditions. In the chemical industry, they manage the flow of reactive and corrosive chemicals. This ensures safe and efficient production by controlling pressure and temperature.

Power generation, both thermal and hydropower, relies on gate valve castings. They regulate the flow of steam and water. This is crucial for maintaining the right pressure and temperature for energy generation. Water treatment plants also use them to start or stop water flow during treatment. This ensures efficient management of water resources.

In manufacturing, industries like food, beverage, pharmaceuticals, and automotive use gate valve castings. They control the flow of liquids and gases, ensuring quality and safety. HVAC systems, the marine industry, fire protection systems, and agricultural irrigation also depend on these castings. They manage fluid flow requirements in these sectors.

| Industry | Application | Criticality of Gate Valve Castings |

|---|---|---|

| Oil and Gas | Upstream, Midstream, Downstream | Controlling flow and pressure of crude oil, natural gas, and refined products |

| Chemical | Chemical processing | Managing flow of reactive and corrosive chemicals |

| Power Generation | Thermal, Hydropower | Regulating steam and water flow for energy generation |

| Water Treatment | Treatment processes | Controlling water flow during treatment |

| Manufacturing | Food, Beverage, Pharmaceuticals, Automotive | Maintaining quality and safety during production |

| HVAC, Marine, Fire Protection, Agriculture | Fluid flow management | Reliable performance for critical applications |

Gate valve castings are crucial in many industries. They ensure efficient and safe control of fluid flow. This is vital for smooth operations in various critical applications.

Conclusion

Gate valve castings are key in controlling fluids, gases, and steam in many industries. KT-FOUNDRY excels in making top-notch gate valve castings through investment casting. This ensures these parts work well for a long time.

Knowing how design, material selection, and manufacturing processes work helps industries choose the right parts. This is crucial for their flow control needs.

Gate valve castings from KT-FOUNDRY are durable, versatile, and precise. They are perfect for water treatment, energy, chemical processing, and more. KT-FOUNDRY keeps improving, offering new gate valve casting solutions for the market.

Using KT-FOUNDRY's gate valve casting technology, industries can improve their systems. This leads to better efficiency and safety in many sectors.