Welding tables are essential tools in any welding workshop, providing a stable and flat surface for various projects. However, rust can quickly become a significant problem, compromising the table's integrity and functionality. This article will explore effective methods to keep your welding table from rusting, incorporating practical knowledge and product details to ensure your table remains in top condition.

Understanding Rust and Its Impact on Welding Tables

Rust is the result of the oxidation of iron when exposed to moisture and oxygen. For welding tables, which are often made from steel, rust can lead to pitting, weakening of the structure, and overall degradation of the work surface. Preventing rust is crucial to maintain the efficiency and longevity of your welding table.

1. Proper Cleaning and Maintenance

Regular cleaning is the first step in rust prevention. After each use, wipe down the table to remove any debris, metal filings, or moisture. Using a wire brush or sandpaper can help remove any initial signs of rust. For deeper cleaning, consider using specialized rust removers available in the market.

Product Tip: Invest in rust remover sprays and anti-rust cleaners. Products like WD-40 or Rust-Oleum can effectively clean and protect your welding table from rust.

2. Applying Protective Coatings

Applying a protective coating to your welding table can significantly reduce the risk of rust. There are several options available, including:

- Paint: A coat of rust-resistant paint can provide a barrier against moisture. Make sure to choose a high-temperature paint to withstand the heat generated during welding.

- Oil: Regularly applying a thin layer of oil can create a protective layer that repels moisture. Machine oils or even linseed oil are good choices.

- Wax: Wax coatings can also be effective in protecting the metal surface from oxidation.

Product Tip: Use Rust-Oleum High Heat Protective Enamel for a durable paint solution. For oiling, consider products like 3-IN-ONE Multi-Purpose Oil.

3. Environmental Control

Controlling the environment around your welding table can help prevent rust. Keep your workshop dry and well-ventilated. Using dehumidifiers can reduce the moisture level in the air, which is a primary cause of rust.

4. Rust-Proofing Your Welding Table

There are various methods to rust-proof your welding table. One effective approach is to use a combination of the aforementioned techniques:

- Surface Preparation: Before applying any coating, ensure the table surface is clean and free of rust. Sandblasting can be an effective method to prepare the surface.

- Coating Application: Apply a primer followed by a rust-resistant paint or oil. Ensure even coverage and allow adequate drying time between coats.

- Regular Maintenance: Periodically check the table for any signs of rust and reapply the protective coatings as necessary.

5. Practical Application Scenarios

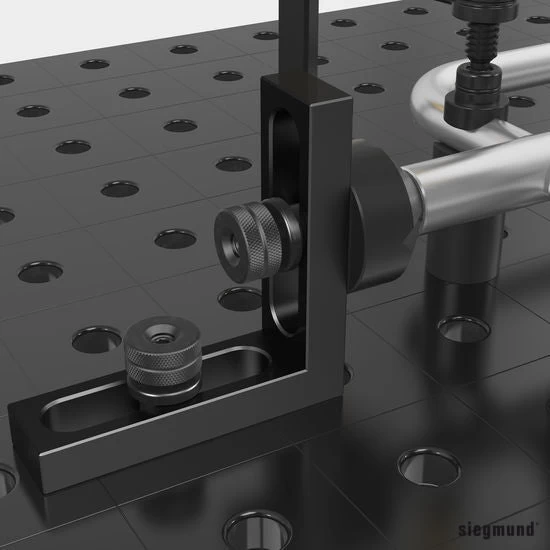

Imagine working on a large steel fabrication project. A rusty table can affect the quality of your welds and slow down your progress. By maintaining a rust-free table, you ensure a smooth surface for accurate and efficient welding. This is particularly important for projects requiring precise measurements and flatness, such as building a flat welding table or creating welding jigs.

Scenario Tip: If you often work with stainless steel pipes welded to your table, keeping the table rust-free ensures the longevity of your equipment and the quality of your welds.

Keeping your welding table from rusting involves a combination of regular cleaning, applying protective coatings, and controlling the environment. By following these practical tips, you can maintain the integrity and functionality of your welding table, ensuring it serves you well for years to come.

For high-quality rust-prevention products and more tips on maintaining your welding equipment, visit our website at kt-foundry. We offer a wide range of solutions tailored to keep your welding projects running smoothly and efficiently.