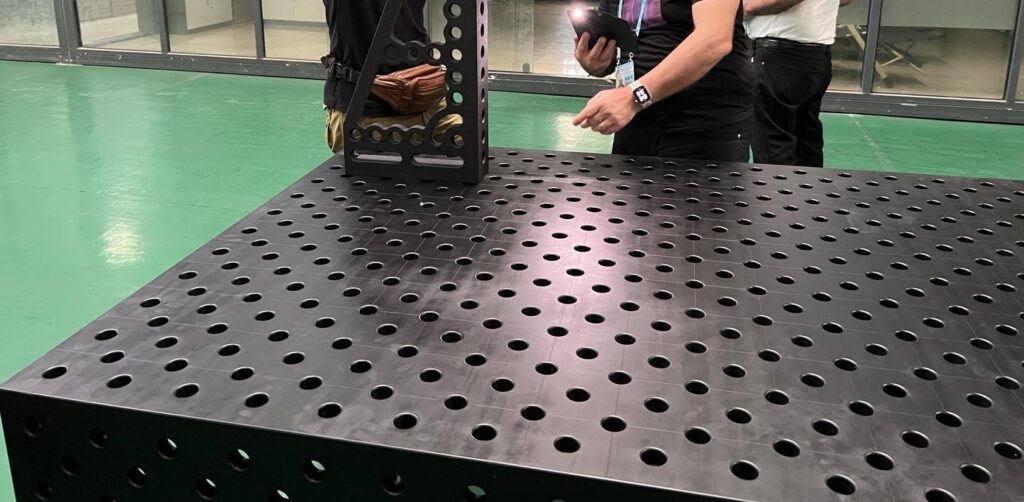

At KT-Welding Table, we aim to give you the best welding tables. A welding table is key for any welding job. It offers a flat, stable area for welding, cutting, and assembling metal.

A sturdy welding table, like those made from cast iron, is crucial. It must have a steel gauge of 11 or more. This prevents warping and ensures durability, making it perfect for fixtures and accessories.

We want to help you pick the right welding table. Whether you're a pro or a hobbyist, our guide is here to assist. We cover features, benefits, and types of welding tables. Plus, we talk about maintenance and customization to help you get the most from your projects.

Understanding Industrial Welding Tables: Core Features and Benefits

Choosing the right welding table is key. It needs to be flat and stable to avoid accidents and ensure quality welds. Steel is a top choice for welding tables because it's durable and high-quality.

The fabrication of these tables must be precise. This ensures they are robust and stable.

Setting up a welding table requires finding the right spot. It should have enough room for all your equipment. The tabletop must be strong to handle high temperatures and heavy use.

A precision welder needs a stable surface for top-notch welds. Plasma cutting also requires a flat area for accurate cuts.

Welding tables boost productivity and accuracy. They also make welding safer by lowering accident risks. When picking a welding table, look at the material and how it's built. A heavy duty table with a robust design offers a solid surface for welding and cutting.

How to Select the Perfect Industrial Welding Table for Your Needs

Choosing the right industrial welding table involves several key factors. The table top's thickness, usually around 16mm, and how it's made are important. A sturdy table with 16mm thickness can handle heavy welding tasks well.

A modular design is popular in the manufacturing world. It offers flexibility and customization. CNC machinery is often used to make welding tables, ensuring precise cuts and designs. For example, a 72 x 48 inch table is great for big projects, while a 20 x 40 inch table is better for smaller items.

When picking a welding table, consider the material. High-quality steel is best because it's strong and resistant to corrosion. The table's surface should be flat to avoid uneven welds. The legs are also important, with options like fixed legs or wheels for easy moving.

Finding the perfect welding table depends on your specific needs. Look at size, material, and fixturing systems. A good welding table, whether for stainless steel or other materials, makes your work easier and improves your welds.

Critical Specifications and Technical Requirements

Choosing the right welding table is key to your success. A flat surface is essential for keeping your work stable and durable. A table that can handle different welding tasks is also important.

The weight your table can hold and its size matter a lot. If you work with heavy pieces, you need a table that can handle it. A horizontal surface makes it easier to move around and work on your projects. The precision of your welds depends on the table's surface and grid patterns.

- Table surface material and durability

- Weight capacity and dimensional considerations

- Grid patterns and surface tolerance

- Fixturing systems and compatibility

By looking at these technical details, you can find a welding table that fits your needs. This will improve your welding work.

| Table Type | Weight Capacity | Dimensional Considerations |

|---|---|---|

| Standard Leg | 6,600 lbs | 21.6" / 550mm height |

| Height Adjustable Leg | 4,400 lbs | 17.7"-27.5" / 450-700mm height range |

Modular Design and Customization Options

We know how important flexibility is in welding tables and accessories. Our goal is to offer the most versatile and customizable welding tables. This way, customers can work efficiently anywhere on the table. Our modular design lets users add or remove fixturing systems and accessories easily.

Our tables come with adjustable and interchangeable components, like fixturing kits. They support up to 1000 lb, perfect for heavy-duty welding. Plus, they have a surface flatness tolerance of ±0.0075”, ensuring a stable work surface.

Our modular design brings many benefits. It increases flexibility, improves productivity, and reduces costs. By customizing their welding setup, users can work more efficiently and effectively. Our tables are durable and long-lasting, with a gross weight of 145 lb and a static load capacity of 1000 lb.

We offer customization options, including different thicknesses from 1/8" inch to 1/4" inch. This lets users choose the perfect table for their needs. With our modular design and customization options, users can create a welding setup tailored to their unique requirements.

By allowing customers to customize their welding tables and accessories, we help them achieve their goals. Whether working with heavy materials or needing precision, our modular design and customization options make it easier. Users can work more efficiently and effectively, anywhere on the table, with our adjustable and fixturing kits.

AT-welding table

Bring Your Designs to Reality– Experience Custom Perfection with On-Demand CNC Machining!

Maintenance and Longevity of Your Welding Table

To keep your welding table from weldtables.com in top shape, regular care is key. This means cleaning the surface and avoiding weld spatter damage. By following these steps, your table will last longer and work better.

Using WD-40 regularly can stop rust by protecting against moisture. Before welding, apply anti-spatter spray to prevent spatter from sticking. Clean with soft tools like nylon or brass brushes to avoid damaging the surface.

For tables with a grid pattern, check for damage like dents or rust often. Using a rust inhibitor can help your table last longer, especially in damp places. weldtables.com has many table accessories to aid in upkeep.

By sticking to these maintenance tips, your welding table will stay in great condition. It will remain a durable and high-quality tool for your projects. Whether you're working with certiflat's or other materials, proper care is crucial for top results.

To make high-quality products, a well-maintained welding table is essential. Investing in a durable and high-quality table from weldtables.com and following maintenance tips will make your table a valuable asset for years.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Apply WD-40 | Weekly | High |

| Inspect for damage | Monthly | Medium |

| Clean with non-abrasive tools | Bi-weekly | High |

Accessories and Enhancement Options

We lead in making welding tables and know how crucial accessories and enhancements are. Our tables have features like threaded holes and vertical frames for better work. We also have clamping systems and fixturing kits to enhance your welding experience.

Our welding tables can be customized to fit your needs. You can add a weld spatter protection system to keep your table safe. They're also great for vertical work, making big projects easier.

Some of our top accessories include:

- BuildPro Rhino Scissor Lift Mobile Working Station

- BuildPro Magnetic Top V-Pad

- BuildPro T-Post Clamp - Pivoting Straight Handle

These accessories boost your welding experience, giving you more control and flexibility. Choosing the right ones can make your work more efficient and your results better.

Conclusion: Making Your Final Decision

Choosing the right industrial welding table is key to better manufacturing. It affects your efficiency and productivity. Look at quality, responsiveness, and durability to find the perfect table for you.

Whether you choose a top-notch, patent-protected table or something more optional, focus on quality and customization. A good welding table has strong braces, reliable grounding, and precise bending. This can greatly improve your workflow and efficiency.

By choosing wisely, you'll make your manufacturing better and deliver great results. A reliable, responsive welding table is essential for success in industrial welding.