In the rapidly evolving world of motor technology, the demand for high-quality, durable components is continually increasing. Aluminum die cast crank housings stand at the forefront of this evolution, offering a blend of strength, thermal conductivity, and corrosion resistance that is unparalleled. This article delves into the sophisticated manufacturing processes of aluminum die cast crank housings and explores their critical role in various industrial applications, highlighting the offerings from KT Foundry.

Introduction to Aluminum Die Cast Crank Housings

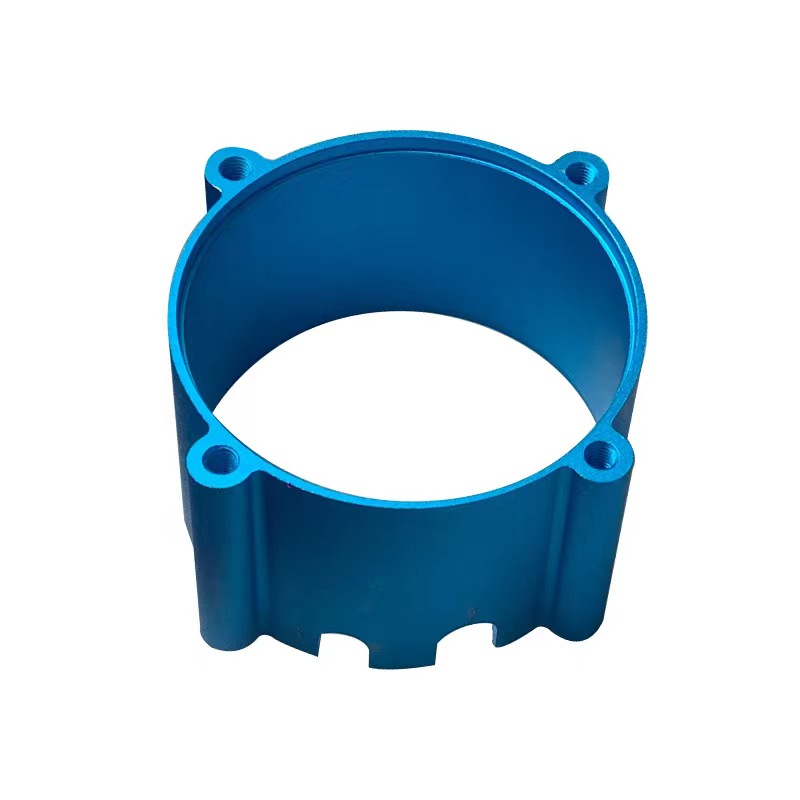

Aluminum die casting is a precision fabrication process used to create complex metal parts by forcing molten aluminum into a mold cavity under high pressure. Among the most significant applications of this technology is the production of crank housings for motors, which are crucial for the proper functioning of various mechanical systems. These housings serve as the skeletal frame of a motor, protecting the internal components while maintaining alignment and reducing vibrations.

Key Attributes and Advantages

The primary advantage of using aluminum for crank housings is its excellent strength-to-weight ratio. Aluminum is lighter than other metals like steel, which is instrumental in reducing the overall weight of the motor and enhancing energy efficiency. Moreover, aluminum’s inherent resistance to corrosion extends the lifespan of the motor housings, especially in harsh environmental conditions.

Another critical attribute is thermal conductivity. Aluminum dissipates heat more effectively than many other metals, which is crucial in preventing overheating and ensuring the longevity of the motor’s components. This makes aluminum die cast crank housings particularly suitable for high-performance applications where thermal management is critical, such as in electric and hybrid vehicles, industrial machinery, and robotics.

Manufacturing Excellence at KT Foundry

At KT Foundry, we specialize in the manufacture of aluminum die cast crank housings, utilizing state-of-the-art technology to ensure precision and quality. Our process begins with the careful design of the mold, which ensures that the final product meets the exact specifications required for each application. We use advanced die casting machines that precisely control the injection of molan aluminum into the mold, achieving superior dimensional accuracy and surface finish.

Practical Applications in Industry

Aluminum die cast crank housings are indispensable in various sectors including automotive, aerospace, and industrial machinery. In the automotive sector, they are used in the construction of lightweight and efficient engines that contribute to fuel efficiency and reduced emissions. In aerospace, these housings are part of the critical components that ensure the reliability and performance of aircraft engines. Similarly, in industrial applications, aluminum crank housings are used in high-speed robotics and assembly lines, contributing to the automation and efficiency of manufacturing processes.

Invitation to Connect

We at KT Foundry are committed to pushing the boundaries of what is possible with aluminum die casting. Whether you are in the automotive, aerospace, or robotics industry, our aluminum die cast crank housings offer the reliability and performance your applications demand. We invite you to visit our website at kt-foundry to explore our full range of products and learn more about how our solutions can benefit your business.

In conclusion, aluminum die cast crank housings are more than just components; they are a testament to the advancements in metallurgical engineering and manufacturing. They play a pivotal role in driving the performance and efficiency of modern mechanical systems, making them indispensable in today’s industrial landscape.