In the world of precision automotive and industrial manufacturing, the role of robust and efficient component housing cannot be overstated. Companies specializing in aluminum die cast clutch housing and motor enclosures are at the forefront of innovations that significantly enhance the performance and longevity of various mechanical and electrical systems. This article explores the critical aspects of aluminum die casting for clutch housings and motor enclosures, spotlighting the technology, applications, and unique benefits of these essential components.

Manufacturing Excellence in Aluminum Die Casting

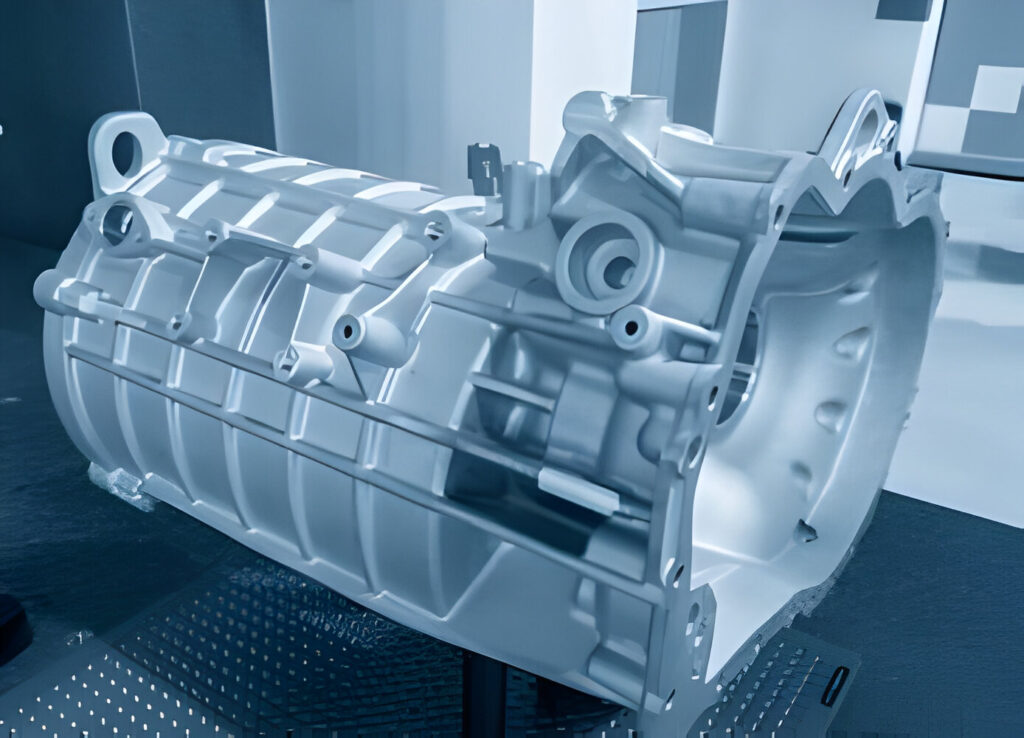

Aluminum die casting is a favored manufacturing process for creating high-strength, lightweight components that are essential in automotive, robotics, and industrial machinery. Clutch housings and motor enclosures, often made from aluminum, benefit from this process due to the metal's excellent thermal conductivity and corrosion resistance. Companies like KT Foundry excel in producing top-tier aluminum die cast houses by leveraging advanced metallurgical technologies and precision machining. These housings are meticulously crafted to meet exact specifications, ensuring optimal performance in demanding environments.

Applications Across Industries

The versatility of aluminum die cast housings extends across various sectors. In the automotive industry, aluminum die cast clutch housings are crucial for protecting the clutch assembly from dust, moisture, and mechanical wear. Similarly, aluminum motor housings are integral in electric vehicles and high-performance engines, providing necessary cooling and structural integrity. Beyond automotive applications, these housings are pivotal in robotics, where they safeguard servo motors and other critical components, enhancing durability and efficiency in automated systems.

Scenarios: Enhancing Durability and Efficiency

One of the standout scenarios for the application of die cast aluminum housings is in high-temperature environments. For instance, electric motor casings designed for industrial motors must withstand extreme conditions while maintaining performance. Aluminum's thermal properties allow for effective heat dissipation, crucial for maintaining motor efficiency and lifespan. Furthermore, the lightweight nature of aluminum contributes to the overall reduction in machinery weight, leading to improved energy efficiency and operational cost savings.

FAQs: Aluminum Die Cast Housings

Q: What are the advantages of using aluminum for clutch housings and motor enclosures? A: Aluminum offers excellent thermal management, corrosion resistance, and strength-to-weight ratio, making it ideal for both automotive and industrial applications.

Q: How does die casting ensure the quality of motor housings? A: Die casting allows for high precision and consistency in manufacturing, producing parts with tight tolerances and excellent surface finishes, which are crucial for assembly and long-term performance.

Q: Can aluminum housings be customized for specific applications? A: Yes, companies like KT Foundry provide bespoke solutions, tailoring the properties and dimensions of the housings to meet specific needs and applications.

For those interested in exploring the wide range of aluminum die cast housings for clutch systems and motors, KT Foundry offers a wealth of options tailored to meet diverse industrial requirements. Our experts are ready to assist with comprehensive solutions that enhance product performance and durability. Visit our website at [kt-foundry] to learn more about our products and how they can benefit your applications. Engage with us today to see how our innovative solutions can propel your projects to new heights.