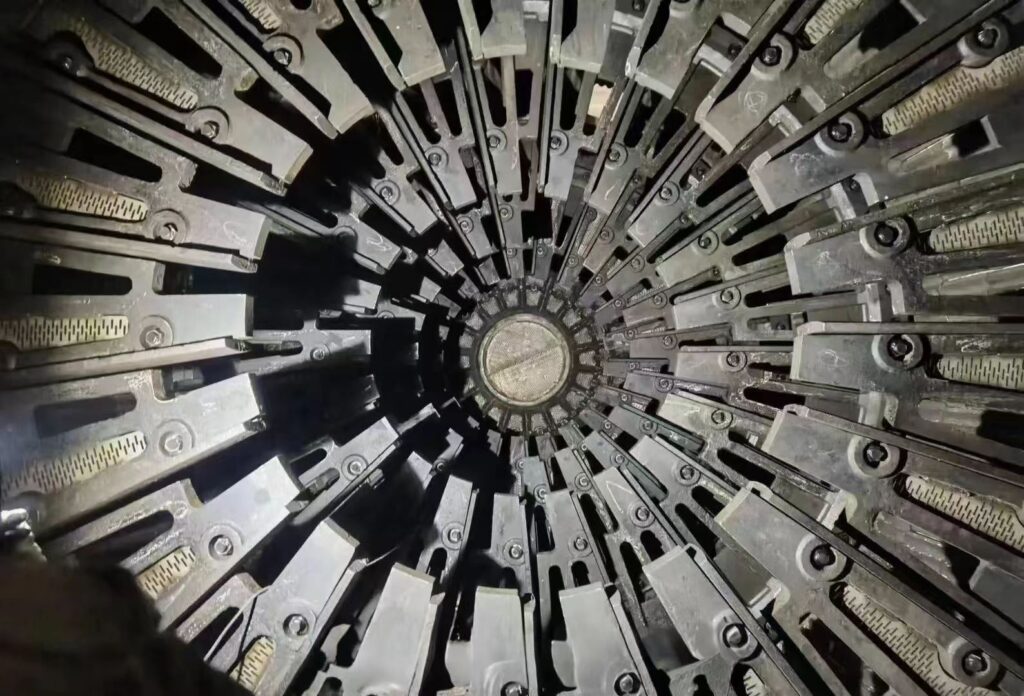

At KT Foundry, we've always believed that innovation is the key to staying ahead in the competitive world of mining and cement production. One area where innovation has made a significant impact is in the materials used for ball mill liners. Over the years, we've developed and refined our KT-ball mill liners using advanced materials that deliver superior performance, durability, and cost-effectiveness. In this article, we’ll explore how innovative materials are transforming ball mill liners and share real-world examples of how our solutions have helped clients achieve remarkable results.

1. The Evolution of Ball Mill Liner Materialsn

Traditionally, ball mill liners were made from materials like manganese steel, which offered decent wear resistance but had limitations in highly abrasive environments. As mining and cement operations became more demanding, the need for more advanced materials became evident.

At KT Foundry, we’ve embraced this challenge by incorporating innovative materials into our KT-ball mill liners. These materials are designed to withstand extreme conditions, reduce wear, and extend the lifespan of your equipment.

2. High-Chrome Alloy: The Gold Standard for Abrasive Environmentsn

High-chrome alloy has emerged as one of the most effective materials for ball mill liners, especially in highly abrasive environments. This material offers exceptional hardness and wear resistance, making it ideal for grinding hard ores like iron, gold, and copper.

We recently worked with a gold mining company in Africa that was experiencing rapid liner wear due to the abrasive nature of their ore. By switching to our KT-ball mill liners made from high-chrome alloy, they achieved a 40% reduction in wear rates. This not only improved their grinding efficiency but also significantly reduced their maintenance costs.

To learn more about our high-chrome alloy liners, visit our Liner Plate page.

3. Rubber Liners: Quiet, Corrosion-Resistant, and Durablen

Rubber liners are another innovative solution that has gained popularity in recent years. These liners are particularly well-suited for applications where noise reduction and corrosion resistance are priorities.

A cement plant in Southeast Asia was facing challenges with noise levels and corrosion due to the acidic nature of their slurry. We recommended our rubber KT-ball mill liners, which not only reduced noise but also improved corrosion resistance. The result was a 20% increase in liner lifespan and a more comfortable working environment for their staff.

4. Composite Liners: Combining the Best of Both Worldsn

Composite liners, which combine metal and rubber, offer a unique blend of durability and impact resistance. These liners are particularly effective in large mills processing hard materials.

We collaborated with a copper mining company in South America that was using traditional steel liners in their large ball mills. After analyzing their process, we recommended our composite KT-ball mill liners. The result was a 15% improvement in grinding efficiency and a significant reduction in energy consumption.

For more details on our composite liners, visit our Liner Plate page.

5. Ceramic Liners: The Future of Ball Mill Liners?n

Ceramic liners are an emerging innovation that offers unparalleled hardness and wear resistance. While still in the experimental phase for some applications, ceramic liners have shown great promise in reducing wear and extending liner lifespan.

At KT Foundry, we’re actively researching and testing ceramic materials to bring this cutting-edge technology to our clients. Early trials have shown a 50% reduction in wear rates compared to traditional materials, making ceramic liners a potential game-changer for the industry.

Why Choose KT Foundry?n

With decades of experience in the industry, KT Foundry has established itself as a leader in ball mill liner manufacturing. Our commitment to innovation, quality, and customer satisfaction sets us apart.

Our KT-ball mill liners are used by some of the largest mining and cement companies worldwide, and our track record speaks for itself. From high-chrome alloy to rubber and composite liners, we offer a wide range of solutions tailored to your specific needs.

Real-World Success Storiesn

Here are a few examples of how our innovative KT-ball mill liners have made a difference:

- Gold Mining in Africa: A gold mining company reduced wear rates by 40% after switching to our high-chrome alloy liners.

- Cement Plant in Southeast Asia: A cement plant achieved a 20% increase in liner lifespan by using our rubber liners.

- Copper Mining in South America: A copper mining company improved grinding efficiency by 15% with our composite liners.

These success stories highlight the tangible benefits of choosing innovative materials for your ball mill liners.

Conclusionn

The materials used in ball mill liners have come a long way, and innovation continues to drive improvements in performance and durability. At KT Foundry, we’re proud to be at the forefront of this evolution, offering KT-ball mill liners that deliver unmatched results.

Whether you’re processing highly abrasive ores or looking to reduce noise and corrosion, we have the right solution for you. To learn more about our products and services, visit our website: https://kt-foundry.com. Let us help you boost your operational efficiency with liners you can trust.

By choosing KT-ball mill liners, you’re not just investing in a product—you’re partnering with a team dedicated to your success. Contact us today to learn more about how we can support your operations.