Investment Casting

What is an Investment Casting?

Investment casting, also known as lost-wax casting, is a manufacturing process that involves creating intricate and precise metal parts by using a wax pattern coated with a refractory ceramic material to form a mold. This method is highly regarded for its ability to produce components with complex geometries, tight tolerances, and smooth surfaces.

Here's how the investment casting process typically works:

Pattern Creation: A wax pattern is created, which is an exact replica of the desired metal part. This wax pattern can be made using injection molding techniques.

Assembly: Multiple wax patterns are often attached to a central wax sprue to form a tree-like assembly, allowing multiple parts to be cast simultaneously.

Shell Building: The wax assembly is dipped into a ceramic slurry, then coated with fine sand. This process is repeated several times to build a thick, sturdy ceramic shell around the wax pattern.

Wax Removal: The ceramic-coated assembly is heated in a kiln to melt and drain away the wax, leaving a hollow ceramic mold.

Metal Pouring: Molten metal is poured into the ceramic mold. The metal takes the shape of the now-empty cavity left by the wax pattern.

Cooling and Shell Removal: After the metal has solidified and cooled, the ceramic shell is broken away, revealing the cast metal part.

Finishing: The individual castings are cut from the central sprue, and any remaining ceramic material is removed. The parts may then undergo further finishing processes such as grinding, machining, or polishing to meet precise specifications.

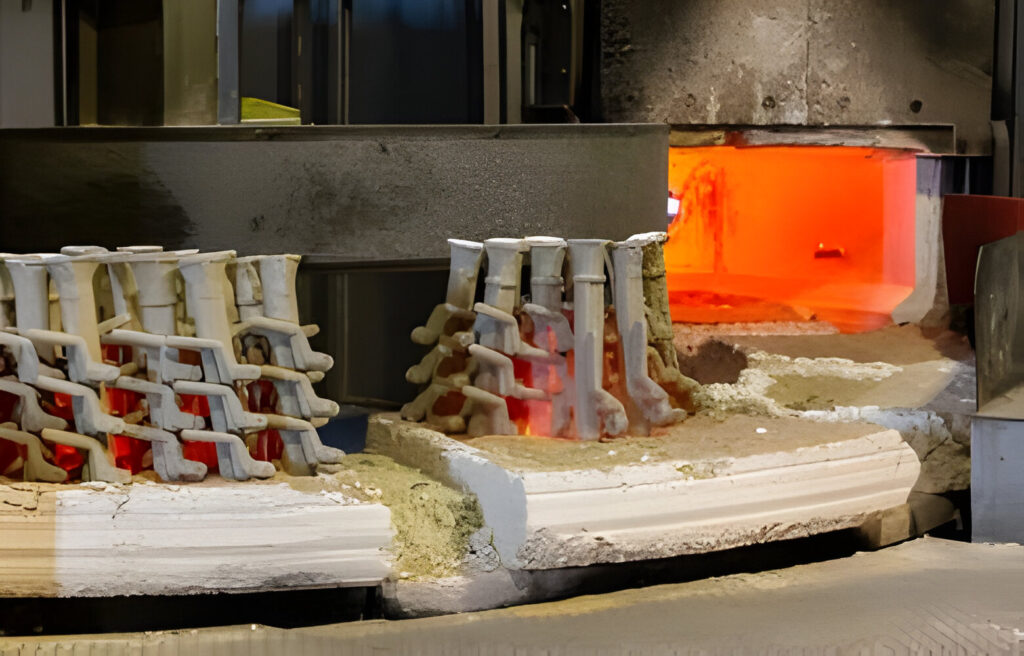

Our company investment casting production process picture

Advantages of Investment Casting Process

- Complex Geometries: Enables the creation of intricate and detailed shapes.

- High Precision: Produces parts with tight tolerances and excellent accuracy.

- Smooth Surface Finish: Provides a smooth finish, often eliminating the need for further treatment.

- Material Versatility: Suitable for a wide range of metals and alloys.

- Reduced Waste: Minimizes material waste, leading to cost-effective production.

- Design Flexibility: Allows for detailed internal and external features.

- Efficiency: Can cast multiple parts in a single mold, increasing production speed.

- Consistency: Ensures high-quality and repeatable parts.

- Minimal Machining: Reduces the need for extensive machining, saving time and costs.

What Materials can be Investment Cast?

1.Stainless Steels: Ideal for parts requiring high strength, corrosion resistance, and heat resistance, such as in aerospace and medical applications.

2.Carbon Steels: Used for components needing high strength and toughness, often in automotive and industrial applications.

3.Alloy Steels: Offers enhanced properties like wear resistance and toughness, suitable for demanding engineering applications.

4.Aluminum Alloys: Lightweight and corrosion-resistant, making them perfect for aerospace, automotive, and consumer goods.

5.Copper Alloys: Includes bronze and brass, known for their excellent corrosion resistance and electrical conductivity, used in plumbing and electrical components.

6.Nickel-Based Alloys: High temperature and corrosion resistance, often used in aerospace and power generation industries.

Our list of investment castings

Why You Should Choose KT-Foundry Investment Casting?

Choosing KT-Foundry for your investment casting needs ensures that you receive top-quality components with unparalleled precision and reliability. Our advanced technology and experienced team guarantee that each part meets your exact specifications, no matter how complex or demanding your requirements are. Here’s why KT-Foundry stands out:

- Expertise: With years of experience in the industry, we have the knowledge and skills to produce high-quality castings.

- Precision: Our state-of-the-art facilities and meticulous processes ensure that each casting meets the highest standards of accuracy and finish.

- Material Versatility: We work with a wide range of materials, including stainless steel, alloy steel, aluminum, and more, to meet your specific needs.

- Customer Focus: We are dedicated to understanding and fulfilling your unique requirements, ensuring complete satisfaction with every order.

- Efficiency: Our efficient production processes and streamlined operations allow us to deliver your parts on time and within budget.

Ready to experience the KT-Foundry difference? Fill out the form below to get started with your investment casting project. Our team will review your requirements and provide a customized solution tailored to your needs.