In the realm of machinery and fluid management systems, the importance of precision cannot be overstated. Every component, no matter how small, plays a crucial role in ensuring optimal performance and reliability. Among these components, pump parts stand out as integral elements that dictate the efficiency and longevity of pumping systems. At KT Foundry, we specialize in the art of pump parts casting, crafting high-quality components that meet the diverse needs of industries worldwide.

The Versatility of Cast Pump Parts

Pump parts casting encompasses a wide range of components, each designed to fulfill specific functions within various pumping systems. From antique hand water pump parts to modern submersible pump casting parts, the versatility of cast pump parts knows no bounds.

Cast Iron Pump Parts: Renowned for their durability and strength, cast iron pump parts are a staple in many pumping applications. Whether it's cast iron hand pump parts for agricultural wells or cast iron water pump parts for municipal water supply systems, our casting process ensures that each component meets the highest standards of quality and performance.

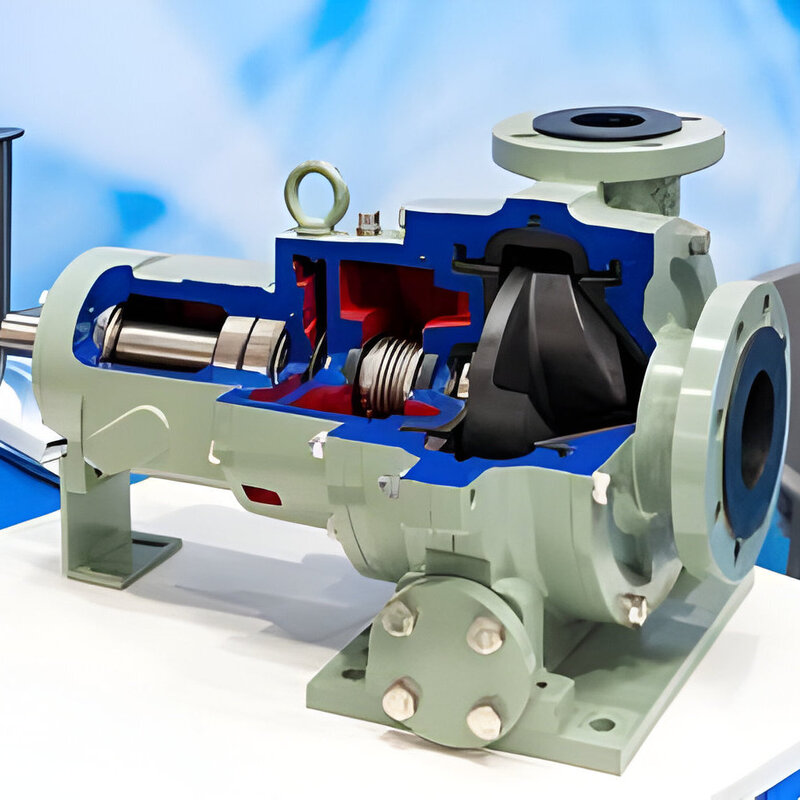

Submersible Pump Casting Parts: In underwater environments where reliability is paramount, submersible pump casting parts reign supreme. From impellers to housings, our precision-crafted components are engineered to withstand the rigors of continuous operation while maintaining optimal efficiency.

Antique Hand Water Pump Parts: Preserving history requires meticulous attention to detail, especially when it comes to antique hand water pump parts. Our casting process allows us to replicate even the most intricate designs, ensuring authenticity and functionality for restoration projects.

The Art of Pump Parts Casting

Behind every flawless pump part lies a meticulous casting process that combines artistry with engineering precision. At KT Foundry, we take pride in our craftsmanship, employing advanced techniques and quality materials to produce components that exceed industry standards.

Advanced Casting Techniques: Our team of skilled craftsmen utilizes state-of-the-art equipment and techniques to achieve unparalleled accuracy in pump parts casting. From investment casting to sand casting, we employ the method best suited to the specific requirements of each component, ensuring consistent quality and dimensional accuracy.

Quality Materials: The foundation of every exceptional pump part is the material from which it's cast. At KT Foundry, we source only the finest metals and alloys, carefully selected for their strength, durability, and corrosion resistance. Whether it's cast iron, stainless steel, or specialized alloys, you can trust that our pump parts are built to last.

Rigorous Quality Control: Quality is not just a goal; it's a commitment that permeates every stage of our casting process. From initial design to final inspection, we adhere to stringent quality control measures to ensure that every pump part meets our exacting standards. Dimensional accuracy, surface finish, and material integrity are meticulously evaluated to guarantee performance and reliability.

Experience the KT Foundry Difference

When it comes to pump parts casting, precision is paramount. At KT Foundry, we combine decades of experience with cutting-edge technology to deliver casting solutions that exceed expectations. From antique hand water pump parts to state-of-the-art submersible pump casting parts, we have the expertise and capabilities to meet your needs.

Contact us today to learn more about our comprehensive range of pump parts casting services and discover how we can help you achieve unparalleled performance and reliability in your pumping systems.