Forklifts and excavators are indispensable workhorses in various industries, aiding in material handling, construction, and excavation tasks. However, ensuring their stability and safety requires meticulous attention to detail, particularly when it comes to calculating the counterweight weight. In this guide, we'll delve into the intricacies of determining the optimal counterweight for forklifts and excavators, shedding light on essential factors and methodologies.

Understanding Forklift Counterweight Weight: Forklifts are designed to lift and transport heavy loads, making stability a paramount concern. The counterweight plays a crucial role in balancing the weight of the lifted load and the forklift itself, preventing tip-overs and ensuring operator safety. Calculating the appropriate counterweight weight involves several key steps:

- Assessing Load Capacity: Begin by determining the maximum load capacity of the forklift. This information is typically provided by the manufacturer and is crucial for calculating the counterweight.

- Estimating Load Weight: Consider the average weight of the loads the forklift will handle regularly. Factor in variations in load weight to ensure sufficient counterbalance under different operating conditions.

- Calculating Moment: The moment arm is the distance between the load's center of gravity and the fulcrum point of the forklift (usually the rear axle). Multiply the load weight by the moment arm to obtain the moment.

- Determining Counterweight: Divide the moment by the distance from the rear axle to the center of gravity of the forklift. This calculation yields the required counterweight to maintain stability.

Excavator Counterweight Considerations: Excavators rely on counterweights to offset the weight of the boom, arm, and bucket during operation. Inadequate counterweighting can lead to instability and compromised performance. Here's how to determine the appropriate counterweight for hydraulic excavators:

- Understanding Machine Configuration: Hydraulic excavators come in various configurations, including standard and long-reach models. Each configuration requires a specific counterweight to maintain stability, with long-reach excavators typically needing additional counterweight due to their extended reach.

- Factoring in Additional Attachments: Attachments such as grapples, rakes, and hydraulic hammers can alter the excavator's center of gravity and weight distribution. Account for the weight of these attachments when calculating the counterweight.

- Consulting Manufacturer Guidelines: Manufacturers provide guidelines and specifications for counterweighting their excavator models. Refer to these guidelines to ensure compliance and optimal performance.

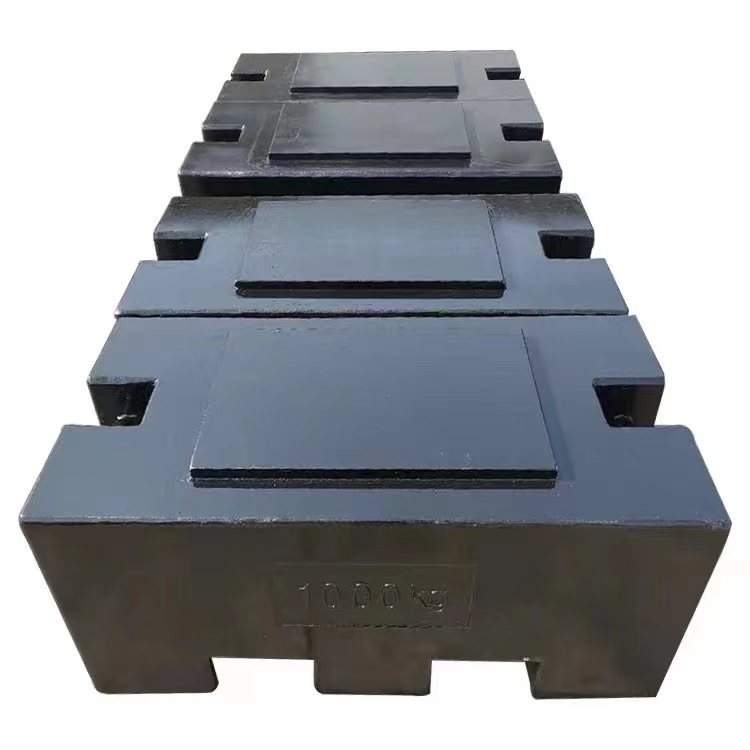

At KT-Foundry, we specialize in producing high-quality counterweights for forklifts and excavators. Our precision-engineered counterweights are designed to enhance stability and safety, meeting the stringent demands of diverse industrial applications. With decades of experience in the field, we prioritize quality, reliability, and customer satisfaction.

Whether you're in need of a forklift counterweight, excavator counterweight, or additional counterweight for specialized equipment, KT-Foundry has you covered. Our expert team can assist you in selecting the right counterweight for your specific requirements, ensuring optimal performance and peace of mind.

Don't compromise on safety and efficiency. Contact us today through our website (kt-foundry) to explore our comprehensive range of counterweight solutions and take your operations to new heights.