In the diverse world of metalworking, precision and durability are paramount, especially when it comes to the infrastructure used in welding processes. Among the most crucial pieces of equipment in any metalworking shop is the welding table, and stainless steel versions offer unmatched benefits due to their robustness and resistance to corrosion. This article explores the pivotal role that stainless steel welding tables play in enhancing workflow and improving productivity, showcasing a range of fully welded and modular options available for purchase at KT Foundry.

Understanding Stainless Steel Welding Tables

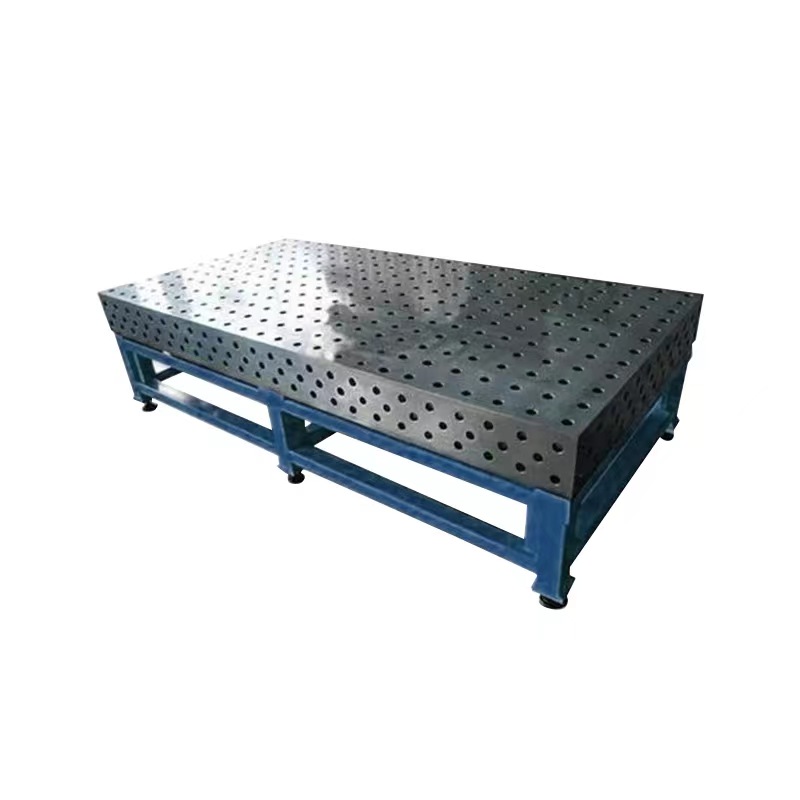

Stainless steel welding tables are prized for their longevity and resistance to heat and corrosion, making them an ideal choice for rigorous welding tasks. Whether you're working on small components or large assemblies, these tables provide a stable and durable surface that withstands the high temperatures and spatter associated with welding. Their smooth, non-porous surface makes them easy to clean and maintain, a vital feature in environments where cleanliness is crucial, such as food processing or medical equipment manufacturing.

Key Features and Advantages

- Durability and Resistance: Made from high-grade stainless steel, these tables resist warping and deterioration over time. Their ability to withstand the intense heat and corrosive byproducts of welding processes makes them a cost-effective investment for any fabrication shop.

- Hygienic and Easy to Clean: The non-porous nature of stainless steel prevents bacteria buildup and contamination, which is essential for projects requiring stringent hygiene standards.

- Versatility: Whether you opt for a fully welded stainless steel table or a model with a modular design, these tables can be customized with various fixtures and fittings, such as clamps and hooks, to suit different welding tasks.

Practical Applications and Scenarios

In practical terms, stainless steel welding tables cater to a wide array of industries. For instance, in the automotive sector, these tables facilitate the precise welding of exhaust systems and frames. In the aerospace industry, their resistance to thermal distortion is crucial for maintaining the integrity of critical welds on aircraft components.

Product Highlights at KT Foundry

At KT Foundry, we offer a selection of stainless steel welding tables that cater to both general and specialized metalworking needs:

- Fully Welded Stainless Steel Table: Ideal for heavy-duty applications, this table is designed as a solid, one-piece unit that offers maximum stability and support.

- Stainless Steel Welding Table with Adjustable Features: This table comes equipped with adjustable legs and optional accessories, making it suitable for tasks that require varying heights and configurations.

- Stainless Steel Machine Tables: These are perfect for supporting auxiliary equipment or integrating with larger manufacturing systems, enhancing overall workflow efficiency.

Engage with Us

Discover how our stainless steel welding tables can transform your production line by visiting our website at KT Foundry. Our team is ready to assist you in selecting the perfect welding table to meet your specific needs, ensuring that you get the most out of your investment. Contact us today to explore our products and find out more about their practical applications in your industry.