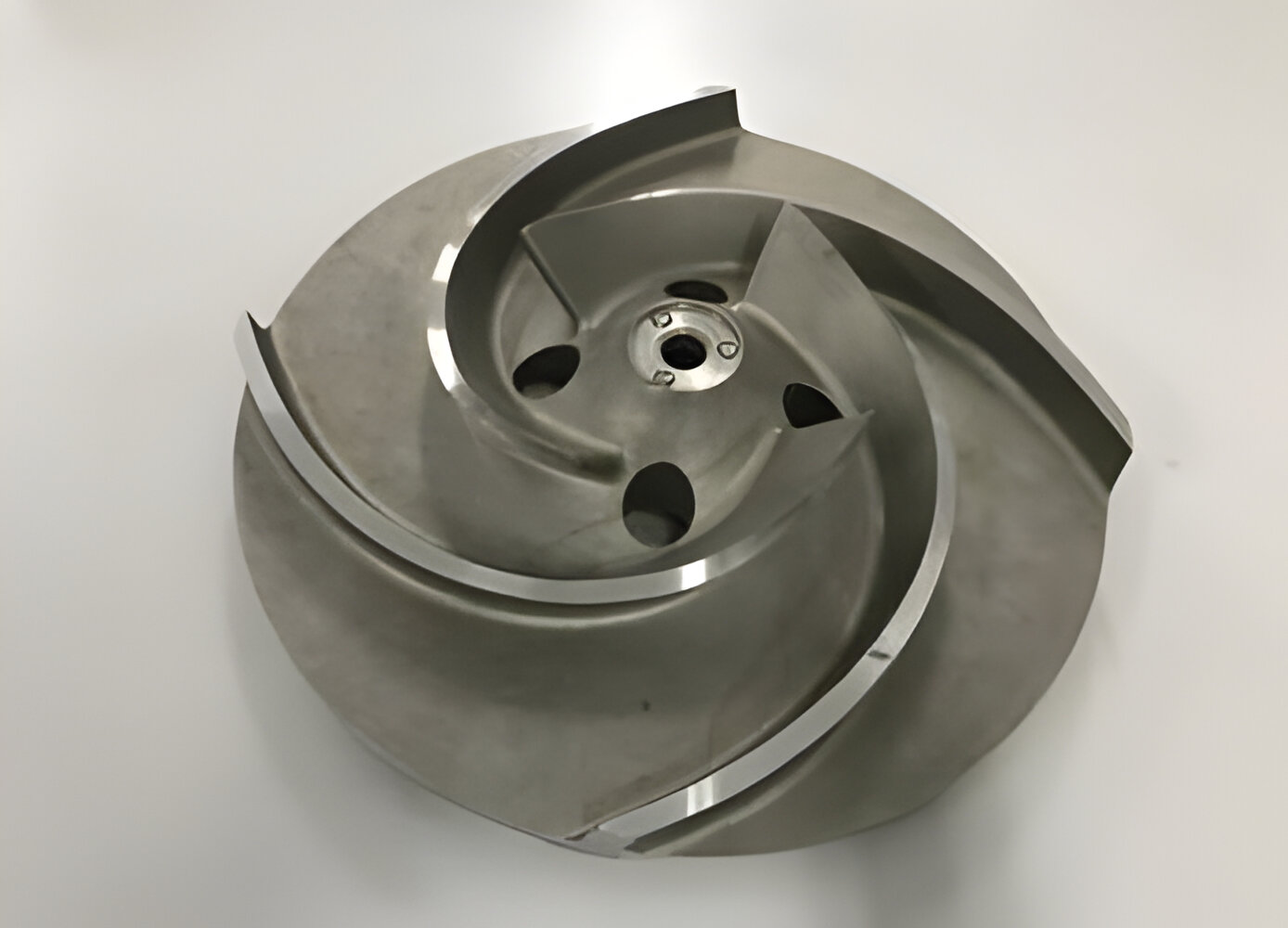

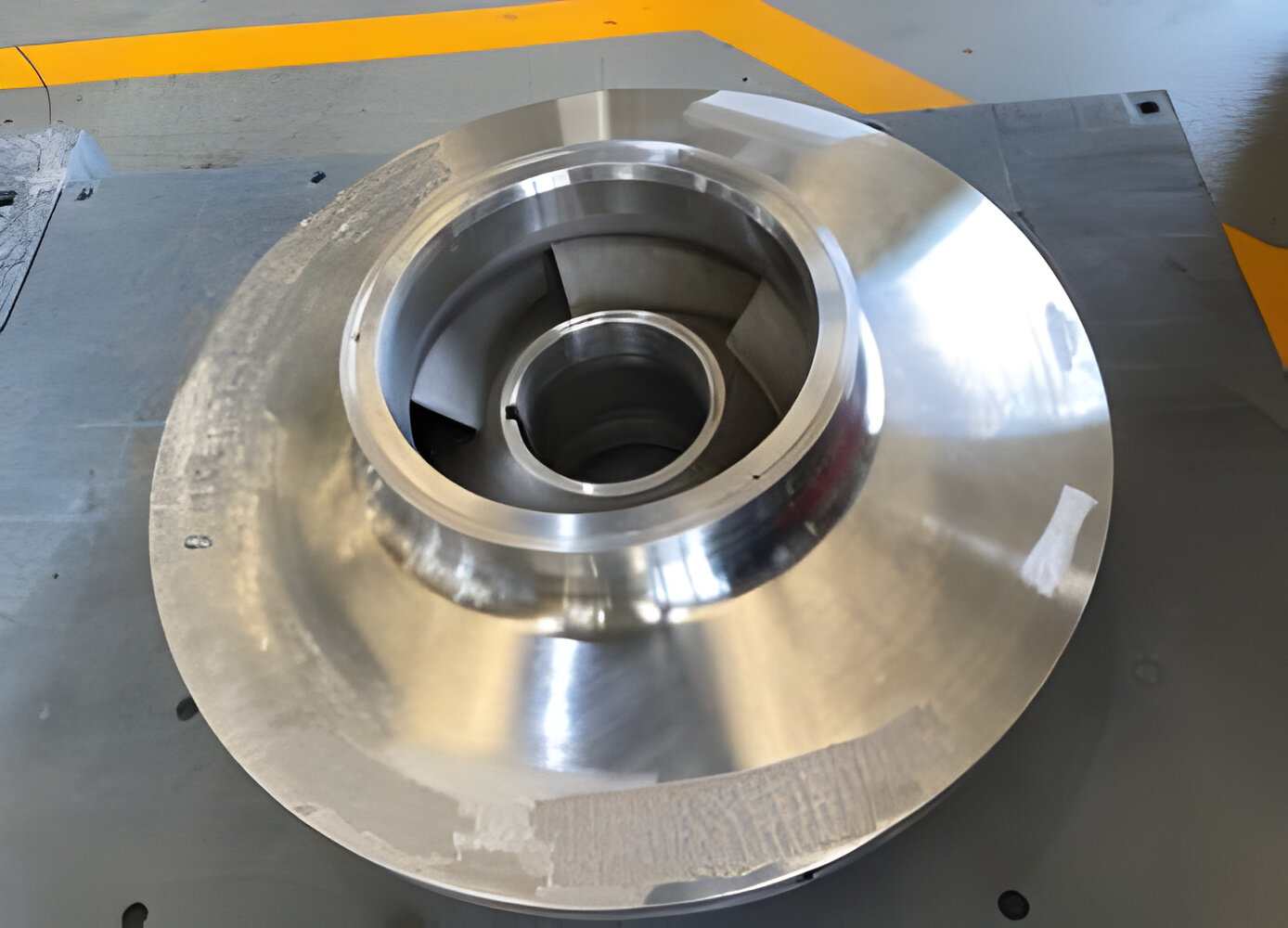

Stainless Steel Impeller Casting

Stainless steel impeller casting, often produced through investment casting, is a process used to create high-quality impellers for various applications. Investment casting, also known as lost-wax casting, allows for the production of complex and intricate impeller designs with excellent dimensional accuracy and surface finish. Stainless steel is a popular choice for impeller casting due to its corrosion resistance, durability, and suitability for a wide range of operating conditions. Impellers cast from stainless steel are commonly used in pumps, compressors, turbines, and other machinery where corrosion resistance and high strength are critical. The investment casting process involves creating a wax pattern of the impeller, coating it with a ceramic shell, and then melting the wax to leave a hollow ceramic shell. Molten stainless steel is then poured into the ceramic shell, allowed to solidify, and the shell is broken away to reveal the cast stainless steel impeller. This process results in a high-quality, precise impeller suitable for demanding applications.Stainless Steel Impeller Casting

Ask For Price

Product Price :Get Latest Price

Product Details:

| Material | SS304,SS316,SS304L,SS316L |

| Process | Investment casting |

| Dimensions | Customized Sizes |

| Weight | 0.1-30kg |

| Package | Carton and wooden pallet |

| QC control | 100% QC |

Request

Callback

Callback

Yes! I am Interested

X