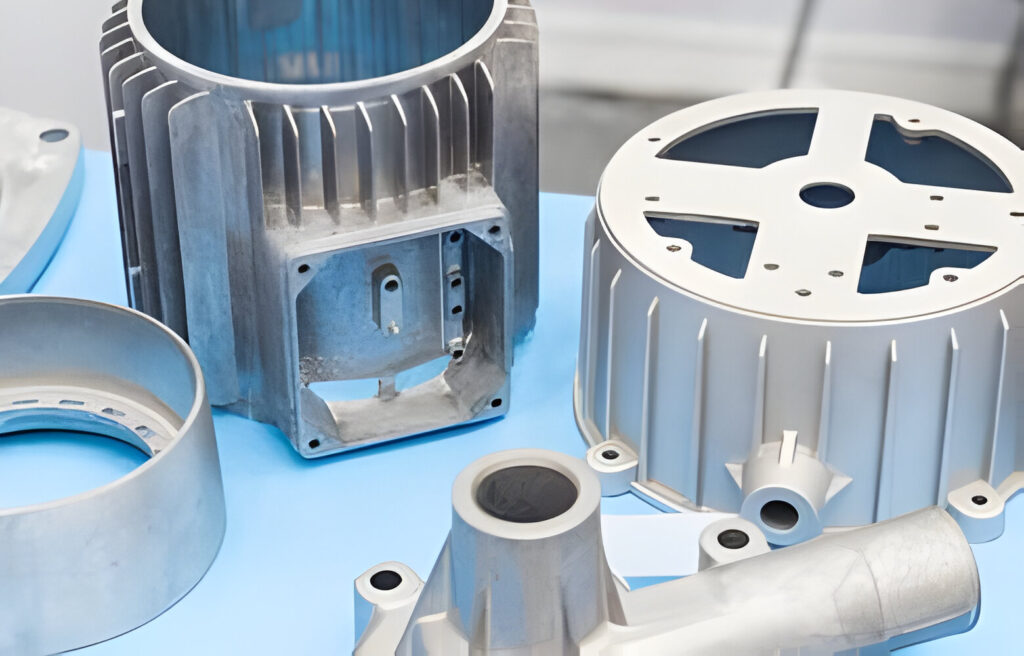

In the rapidly evolving world of industrial machinery, the integrity and performance of component parts are pivotal for operational efficiency. Among these, die casting mould housings stand out as crucial elements in various applications, particularly in motor assemblies. Utilizing high-quality materials like aluminum, these housings offer a blend of durability, conductivity, and light weight, making them indispensable in modern engineering.

Introduction to Die Casting Mould Housings

Die casting is a precision manufacturing process where molten metal is injected under high pressure into a mould cavity. This method is particularly well-suited for producing complex shapes with high dimensional accuracy and smooth finishes. Aluminum, known for its excellent strength-to-weight ratio, is commonly used in die casting for motor housings, offering enhanced performance and longevity.

Key Applications and Scenarios

Die casting mould housings are integral to various sectors including automotive, aerospace, and industrial machinery. In automotive applications, aluminum die cast motor housings are crucial for reducing vehicle weight, thereby improving fuel efficiency and reducing emissions. In aerospace, the lightness and strength of aluminum motor housings contribute to the overall structural integrity and performance of aircraft.

Manufacturing Excellence

At the heart of die casting mould housing production is the choice of material and the precision of the casting process. Our aluminum die casting housings are manufactured using state-of-the-art technology to ensure tight tolerances and high-quality finishes. The process involves several steps including melting the aluminum, injecting it into steel dies at high pressures, and a meticulous cooling process that enhances the mechanical properties of the housing.

FAQs About Die Casting Mould Housings

- What advantages does aluminum offer in die casting housings? Aluminum is lightweight, highly conductive, and offers excellent corrosion resistance, making it ideal for motor and electric housings in harsh environments.

- Can die casting be used for custom motor housing designs? Absolutely. Die casting is highly versatile and can be tailored to meet specific design requirements, allowing for the integration of complex features and fine details without sacrificing structural integrity.

- How do die cast housings improve motor efficiency? The thermal conductivity of aluminum helps dissipate heat efficiently, essential for maintaining optimal operating temperatures in electric motors and reducing the risk of overheating.

Why Choose Us?

At KT Foundry, we specialize in aluminum die casting for motor housings, combining innovative technology with deep industry expertise to deliver products that meet the highest standards of quality and performance. Our solutions cater to a wide range of applications, ensuring that each product not only meets but exceeds client expectations.

We invite you to explore the possibilities with our die casting solutions. For more information or to discuss your specific needs, please visit us at kt-foundry. Our team is ready to assist you in selecting the right components for your projects, ensuring your machinery operates at its peak potential.