SAND CASTING SERVICES

What is Sand Casting?

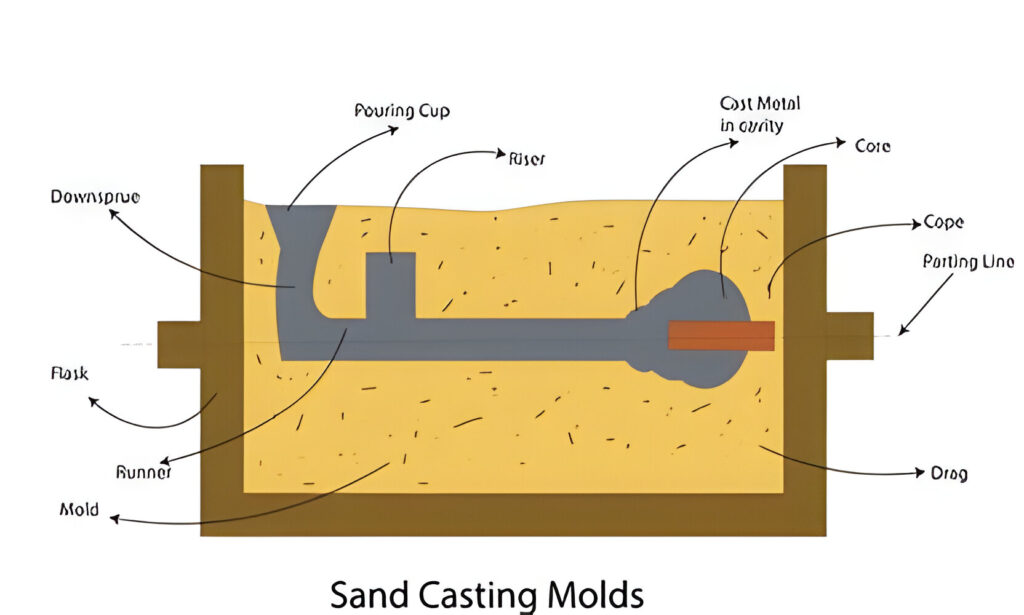

Sand casting is a traditional and widely-used manufacturing process for creating metal parts by pouring molten metal into a sand mold. The mold is made by compacting sand around a pattern of the desired shape, which is then removed to leave a cavity. After the metal solidifies, the mold is broken away to reveal the cast part. Sand casting is versatile, cost-effective, and suitable for producing complex shapes and large parts in various metals, including aluminum, iron, and steel.

Our Sand Casting Process

Green sand casting is a widely-used metal casting process that employs a mixture of sand, clay, and water to create molds. The term "green" refers to the moisture content in the mold material. This method is cost-effective and versatile, making it suitable for producing a wide range of metal parts, from small to large sizes. Green sand casting is popular due to its simplicity, ability to produce complex shapes, and adaptability to various metals.

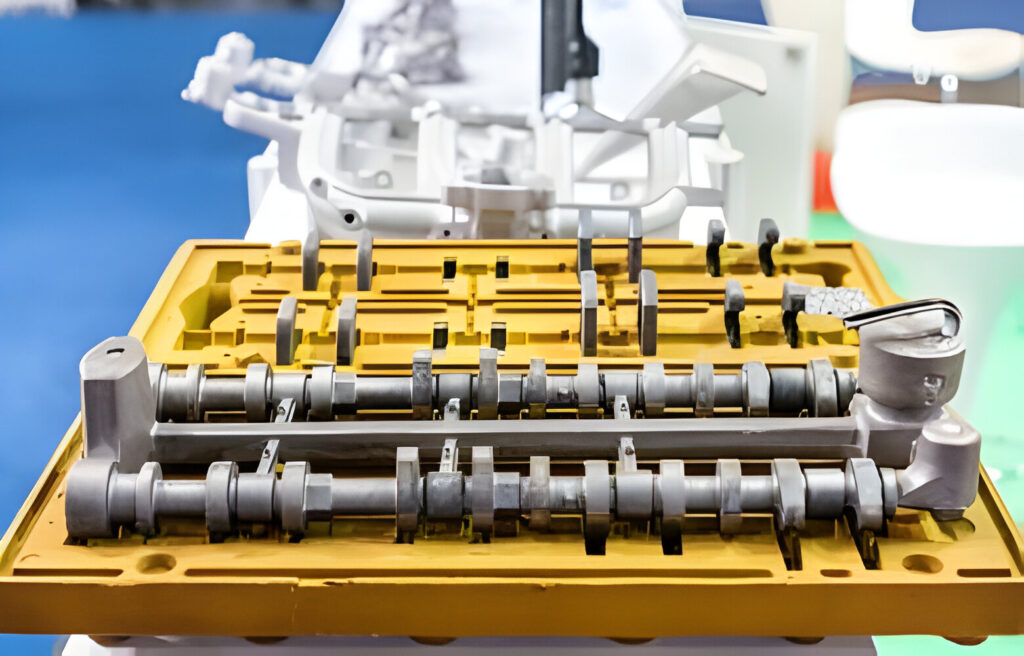

Shell molding is a precision casting technique that uses a thin shell of sand bonded with a thermosetting resin to create molds. The process involves coating a heated pattern with the sand-resin mixture, which hardens to form a shell. This method offers better dimensional accuracy and a smoother surface finish compared to traditional sand casting. Shell molding is ideal for producing complex and high-precision metal parts with intricate details.

Shell Molding

Green Sand Casting

Applications and Advantages of Sand Casting

Applications of Sand Casting:

- Engine blocks

- Pipe fittings

- Agricultural machinery

- Mining equipment

- Pump housings

Advantages of Sand Casting:

- Cost-effective for low to medium production volumes

- Capable of producing complex shapes

- Wide range of metal options

- Scalable for small to large parts

- Suitable for both ferrous and non-ferrous metals

Our shell production process

- Equipped with 12 shell molding machines

- Ensure high production efficiency for clients

- Rapid response time for customer needs

Our Offerings

kt-foundry offers high quality sand casting services

At KT-Foundry, we pride ourselves on delivering high-quality sand casting services. With 12 advanced shell molding machines, we guarantee exceptional production efficiency and a quick response time to meet your needs. Our experienced team is dedicated to ensuring your satisfaction with every project. To get started, please fill out the form below.