At KT-Foundry, we know how important stainless steel castings are for today's industries. This process makes strong, resistant, and precise parts by pouring stainless steel into molds. It's key in construction, chemical, and food processing, where stainless steel's unique qualities are vital.

Stainless steel is a mix of at least 10.5% chromium and iron. Chromium gives it great resistance to corrosion. This makes it perfect for many industrial uses. As a top provider of stainless steel castings, we're eager to share our knowledge with you.

Introduction

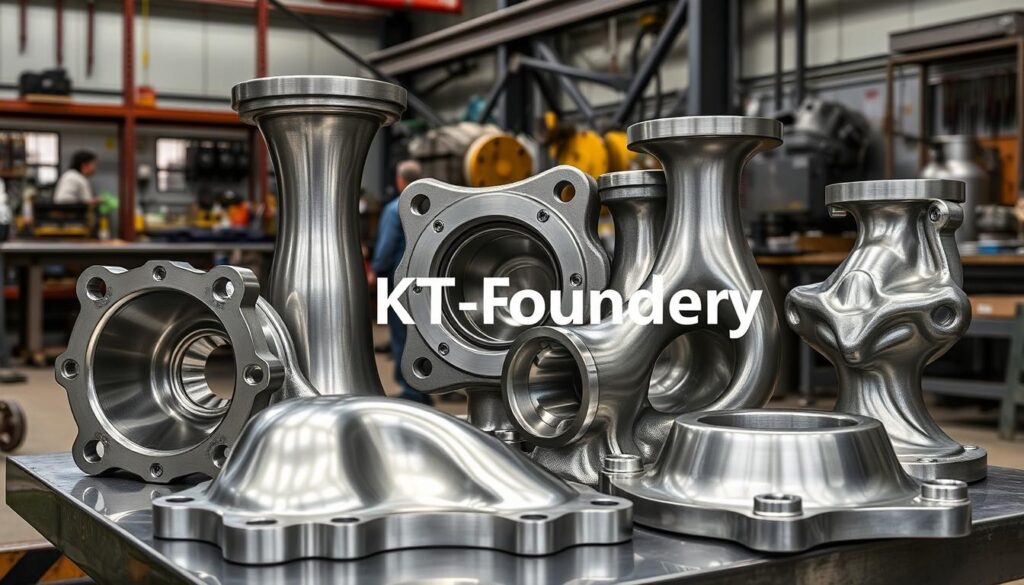

Stainless steel castings are key in many industries today. They are made by pouring molten steel into molds. This creates complex shapes that other methods can't match.

Their properties like corrosion and heat resistance are unmatched. This makes them vital in many areas.

Why They Are Crucial in Today's Industries

- Corrosion resistance: They are perfect for harsh environments, like chemical plants and marine gear.

- Heat resistance: They can handle high temperatures, great for industrial and automotive parts.

- High strength: They are durable, needed for heavy-duty items like construction and medical implants.

- Hygiene and cleanliness: Their non-porous nature makes them ideal for food and medical equipment.

These qualities make stainless steel castings essential in many fields. This includes the automotive, aerospace, and chemical industries.

Understanding the Basics of Stainless Steel Castings

Stainless steel is known for its great properties like being resistant to corrosion, durable, and looking good. The key to making the most of stainless steel is the casting process. This process turns this amazing material into many high-performance products.

What is Stainless Steel?

Stainless steel is mostly iron, carbon, and chromium (at least 10.5%). Adding nickel, molybdenum, and titanium can make it even better. This makes stainless steel perfect for many industries.

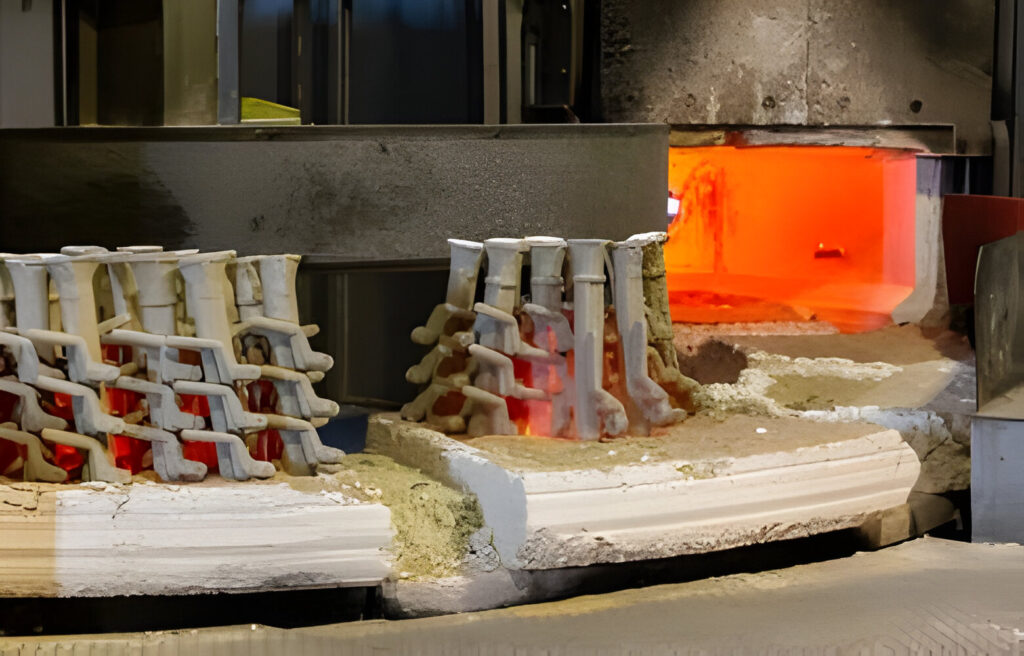

The Casting Process: Step-by-Step Explanation

- Pattern Creation: Crafting a pattern to form the mold.

- Mold Preparation: Using sand or ceramic molds to achieve precise dimensions.

- Pouring and Cooling: Filling the mold with molten steel and allowing it to solidify.

- Finishing: Removing excess material and performing surface treatments.

Stainless steel grades

Stainless steel castings come in many grades, each for different needs. Some common ones are:

- Ferritic stainless: 430, 444, 409

- Austenitic stainless: 304, 302, 303, 310, 316, 317, 321, 347

- Martensitic stainless: 420, 431, 440, 416

- Duplex stainless: 2304, 2205

Foundries can also make custom alloys for special needs in different industries.

"Stainless steel castings offer a reliable process control and repeatability, allowing us to achieve tight tolerances and deliver precision components to our clients across a wide range of industries."

Key Properties of Stainless Steel Castings

Stainless steel castings have many great qualities. They are strong, durable, and resistant to many things. This makes them a top pick in many fields.

Mechanical Properties: Tensile Strength and Hardness

Stainless steel castings are very strong and hard. This is key for parts that face a lot of stress. The chromium in them helps make the material even stronger.

Resistance Properties: Corrosion, Heat, and Wear Resistance

Stainless steel castings are also great at fighting off corrosion, heat, and wear. The chromium in them creates a protective layer. This helps keep the material safe from harm.

Design Flexibility and Precision

The casting process lets designers make complex shapes. Methods like investment casting can make parts very accurate and smooth. This makes stainless steel castings perfect for detailed work.

Stainless steel castings are versatile and reliable. They are used in many areas, like power generation, industrial equipment, transportation, and medical devices.

KT-Casting

Bring Your Designs to Reality– Experience Custom Perfection with On-Demand Casting!

At KT-FOUNDRY, we provide custom stainless steel castings that maintain these properties across various applications.

Advantages of Using Stainless Steel Castings

Stainless steel castings are a top choice for many industries. They improve product performance, are cost-effective, and scalable. These materials offer a unique mix of features for modern manufacturing needs.

1. Performance Reliability Under Extreme Conditions

Stainless steel castings are engineered to perform exceptionally well in harsh environments. Their inherent properties, such as resistance to high temperatures, pressure, and corrosive substances, make them ideal for critical applications in industries like oil and gas, aerospace, and marine. These castings maintain structural integrity and performance under extreme mechanical and environmental stress, ensuring operational reliability.

2. Reduction in Long-Term Operational Costs

While stainless steel castings may have a higher upfront cost compared to alternative materials, their durability and corrosion resistance significantly lower maintenance and replacement expenses. This cost-effectiveness translates to fewer disruptions and higher efficiency over the product's lifecycle, making them a smart investment for businesses aiming to reduce long-term operational costs.

3. Compatibility with Various Industries and Customization Needs

Stainless steel castings are highly versatile and can be tailored to meet the unique requirements of diverse industries. Whether for intricate medical devices, robust automotive components, or complex industrial machinery, these castings offer design flexibility to achieve specific functional and dimensional needs. Manufacturers like KT-FOUNDRY specialize in producing customized castings that align with industry-specific standards and applications, ensuring an optimal fit for every project.

"Stainless steel castings offer the perfect blend of durability, precision, and cost-efficiency, making them an essential component in a wide range of industries."

Stainless steel castings are incredibly versatile. They are used in mining, wastewater treatment, energy, and food processing. By using these castings, businesses can improve product performance, save costs, and be more environmentally friendly.

Real-World Applications

Stainless steel castings are key in many fields like the energy sector, food processing, chemical industry, marine applications, aerospace, and medical devices. They are chosen for their top-notch qualities. This makes them perfect for many uses.

Case Study: Custom Stainless Steel Casting for the Oil & Gas Sector

At KT-FOUNDRY, we recently completed a project for a client in the oil and gas industry. The challenge was to design and manufacture stainless steel valve components capable of withstanding extreme temperatures and corrosive environments.

Project Details:

| Requirement | KT-FOUNDRY Solution |

|---|---|

| High corrosion resistance | Austenitic stainless steel casting |

| Intricate valve geometry | Precision molding techniques |

| Durability in extreme temperatures | Heat-treated stainless steel alloy |

Result: The client reported a 25% reduction in maintenance downtime and improved operational efficiency.

This project highlights our capability to deliver customized solutions that meet industry-specific challenges. Visit our projects page for more examples.

Powering the Energy Sector

In the energy sector, stainless steel castings are crucial. They are used in gas turbines and boiler systems. Their ability to withstand high heat and last long is vital.

Stainless steel castings also ensure these systems work well and reliably. This is because they resist corrosion and are made with precision.

Real-World Applications of Stainless Steel Castings

Industries Leveraging Stainless Steel Castings

| Industry | Applications |

|---|---|

| Automotive | Exhaust systems, turbocharger components |

| Aerospace | Engine components, structural fittings |

| Food Processing | Sanitary equipment, mixing blades |

| Medical Equipment | Surgical tools, orthopedic implants |

To explore how stainless steel castings fit your industry’s needs, check our application guide.

Stainless steel castings are also used in aerospace and medical devices. They are known for their precision, reliability, and high performance. This makes them perfect for complex aerospace parts and medical implants and tools.

Using stainless steel castings helps businesses improve their products. They make products last longer and work better. This means customers get more value. The versatility and capabilities of stainless steel are key for many important uses.

Conclusion

This guide has covered the amazing benefits of stainless steel castings. They are strong, resistant to corrosion, and cost-effective. These qualities make them key in many fields, like aerospace and medicine.

Why Choose KT-FOUNDRY for Stainless Steel Castings?

At KT-FOUNDRY, we combine advanced technology and expertise to produce stainless steel castings of the highest quality. From consultation to final delivery, our team ensures precision, durability, and compliance with international standards.

Key Advantages of Working with Us:

- Customization for unique project requirements

- Rigorous quality control at every production stage

- Competitive pricing and reliable delivery timelines

Learn more about our stainless steel casting services or contact us for a consultation.

Call to action: Why businesses should consider stainless steel castings

Businesses looking to improve their products should think about stainless steel casting. It's strong, versatile, and can give you an edge in the market. Working with experts like KT-Foundry can help you innovate and grow.

kt-Casting

Bring Your Designs to Reality– Experience Custom Perfection with On-Demand Casting!

Can you cast stainless steel?

Yes, stainless steel can be cast. It’s a popular choice for its durability, corrosion resistance, and precision in complex shapes.

At KT-FOUNDRY, we provide high-quality stainless steel castings tailored to diverse industries. Learn more on our services page or contact us.

What is the best stainless steel for casting?

The best stainless steel for casting depends on the application, as each type offers unique properties. Common options include:

Austenitic Stainless Steel (e.g., 304, 316)

- High corrosion resistance and excellent toughness.

- Ideal for food processing, chemical equipment, and marine applications.

Martensitic Stainless Steel (e.g., 410, 420)

- High strength and wear resistance.

- Common in turbine blades and surgical instruments.

Ferritic Stainless Steel (e.g., 430)

- Good resistance to stress corrosion cracking.

- Used in automotive parts and industrial valves.

At KT-FOUNDRY, we guide clients in choosing the best stainless steel grade for their specific casting needs. Explore our custom casting services for more details.

What is the easiest stainless steel to cast?

The easiest stainless steel to cast typically falls within the austenitic stainless steel category, such as 304 or 316 stainless steel. These grades are widely favored for casting because they:

- Melt and Flow Easily: Austenitic stainless steels have excellent fluidity in molten form, making them suitable for intricate designs and complex molds.

- Provide High Corrosion Resistance: They are less likely to oxidize during casting, ensuring better quality outcomes.

- Are Versatile: They can be used for a wide range of applications, from industrial machinery to consumer goods.

At KT-FOUNDRY, we specialize in casting these and other stainless steel grades, ensuring efficient production and superior results. For tailored solutions, visit our services page.