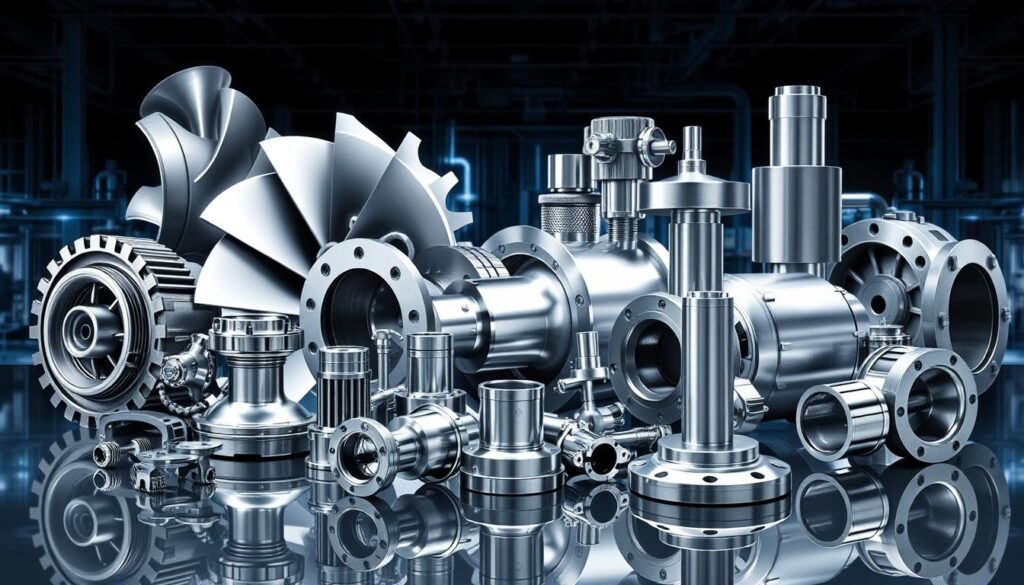

In the world of manufacturing, precision is key. Stainless steel investment casting is a game-changer for making detailed metal parts. This guide explores the world of stainless steel investment casting, its benefits, and the special process it uses.

Stainless steel is known for its strength, resistance to corrosion, and good looks. It's the top choice for many industries. Investment casting lets us use stainless steel's strengths to make parts that meet high standards. Let's dive into the details of stainless steel investment casting and why it's great for precision manufacturing.

What Is Stainless Steel Investment Casting?

Stainless steel investment casting is a modern method rooted in ancient lost-wax casting. It combines stainless steel alloys with the precision of investment casting. This way, manufacturers can make complex, high-quality parts for many industries.

The investment casting process is known for its accuracy and surface finish. Stainless steel is chosen for its strength and resistance to corrosion. This makes it perfect for industries like aerospace, automotive, medical, and construction.

"Stainless steel investment casting is a game-changer in the world of precision manufacturing. It allows us to create complex, high-performance components that push the boundaries of what's possible."

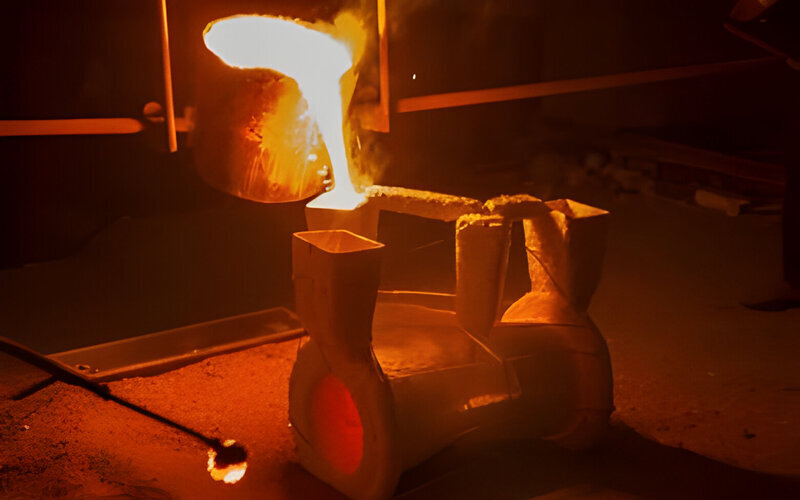

The lost wax casting method is key to investment casting. It starts with a wax pattern of the part, then a ceramic shell is built around it. The wax is melted, leaving a cavity. Molten stainless steel is poured in, solidifying into the final product.

Stainless steel investment casting opens up new possibilities for manufacturers. It lets them create parts that are both beautiful and functional. This technique is now a crucial part of modern manufacturing.

Common grades of stainless steel used in investment casting

In investment casting, we have many stainless steel grades to pick from. Each has its own special properties and uses. The most used are austenitic, martensitic, and duplex stainless steels.

Austenitic stainless steels, like 304 and 316, are great for resisting corrosion and being flexible. They are very versatile. They're used in many fields, from food processing to making medical equipment.

Martensitic stainless steels are known for their strength and hardness. The 17-4 PH grade is often chosen for parts needing high mechanical strength. This is true for aerospace and defense.

Duplex stainless steels offer a mix of strength, corrosion resistance, and toughness. They're perfect for parts facing tough environments. This makes them ideal for investment casting.

| Stainless Steel Grade | Key Properties | Common Applications |

|---|---|---|

| 304 Stainless Steel | High corrosion resistance, good ductility | Food processing equipment, medical devices, architectural applications |

| 316 Stainless Steel | Excellent corrosion resistance, higher strength than 304 | Chemical processing equipment, marine applications, medical implants |

| 17-4 PH Stainless Steel | High strength, hardness, and wear resistance | Aerospace components, industrial machinery, sports equipment |

| Duplex Stainless Steel | Combination of strength, corrosion resistance, and toughness | Oil and gas industry, marine environments, chemical processing |

Knowing the special traits of these stainless steel grades helps us choose the best one for our needs. This ensures we make high-quality, durable, and reliable parts.

Why Choose Stainless Steel for Investment Casting?

Stainless steel is a top choice for precision components because of its great performance and flexibility. At KT Foundry, we see the many benefits of stainless steel in investment casting. It has corrosion resistance and a perfect surface finish, making it great for many industries.

One big plus of stainless steel investment casting is its corrosion resistance. It's perfect for places where things get very corrosive. This means it lasts longer and works better in harsh environments. It's great for the marine, chemical, and food processing fields.

Stainless steel also has a superior surface finish. The investment casting method and stainless steel's properties make components look smooth and even. This is a big plus in industries where looks matter a lot, like in electronics and fancy appliances.

Stainless steel investment casting is also very versatile and flexible in design. It can make complex shapes and details, fitting many uses. It's good for car parts, medical tools, and more, because it can be shaped to fit specific needs.

"The benefits of stainless steel investment casting are truly remarkable. It's a material that combines durability, corrosion resistance, and visual appeal, making it an excellent choice for a wide range of precision components."

At KT Foundry, we know how valuable stainless steel investment casting is. We're all about quality and making our customers happy. Our team works hard to give you the best solutions for your precision needs.

The Investment Casting Process

We're proud of our work at our top-notch casting foundry. We specialize in stainless steel investment casting. This process is all about precision and quality.

It starts with making a wax pattern that looks just like the part we want. Then, we cover this wax with layers of ceramic shell. After it hardens, we melt the wax, leaving a cavity for the metal.

- Wax Pattern Fabrication: Our skilled artisans meticulously sculpt the wax patterns, ensuring the highest level of detail and precision.

- Ceramic Shell Coating: The wax patterns are coated with multiple layers of ceramic slurry, forming a sturdy, heat-resistant shell.

- Wax Removal: The ceramic shell is then heated, causing the wax to melt and drain, leaving behind the desired cavity.

- Pouring Molten Stainless Steel: The molten stainless steel is carefully poured into the ceramic shell, filling the cavity with the desired metal.

- Cooling and Solidification: The cast parts are allowed to cool and solidify, ensuring the desired metallurgical properties.

- Ceramic Shell Removal: The hardened ceramic shell is then carefully removed, revealing the finished stainless steel castings.

- Finishing and Inspection: The cast parts undergo meticulous finishing and quality inspection to meet the most stringent industry standards.

Each step needs a deep understanding of materials and precision. Our team makes sure every casting meets top standards. We deliver the best results for our clients.

"The investment casting process is a true testament to the power of precision and attention to detail. Our foundry is committed to pushing the boundaries of what's possible in stainless steel manufacturing."

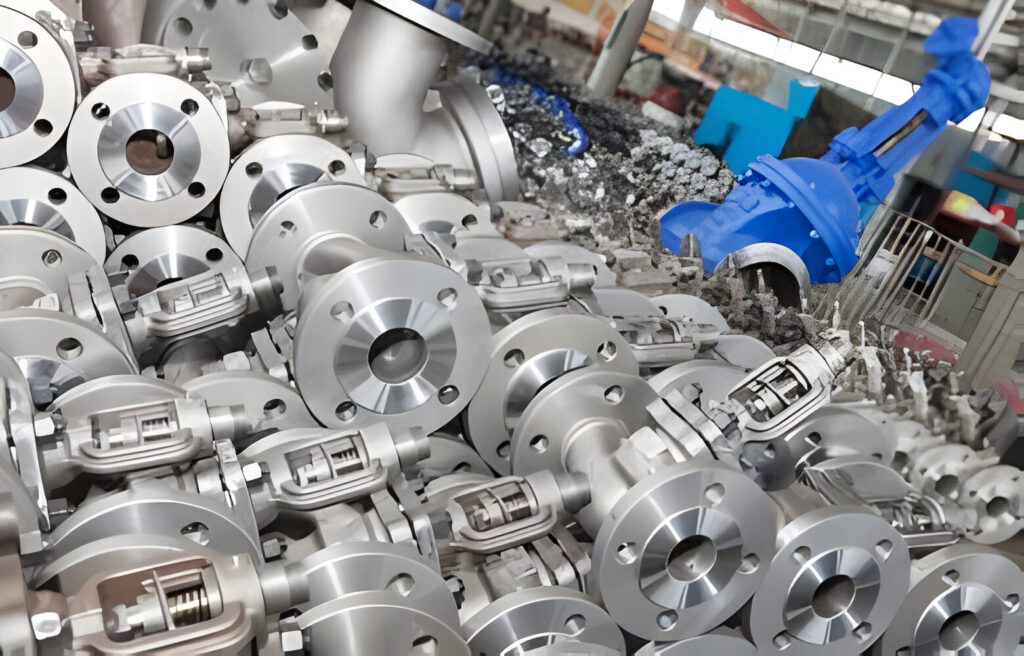

Applications of Stainless Steel Investment Castings

Stainless steel investment castings are used in many industries. They are key in modern manufacturing. These parts are vital in fields like aerospace, medicine, cars, and marine use.

In aerospace, they make engine parts, landing gear, and more. Their strength, resistance to corrosion, and light weight are perfect for aircraft.

The medical field uses them for surgical tools, implants, and more. Their precise making and clean properties ensure safety and reliability in healthcare.

Car makers use them for engine parts, suspension, and exhaust systems. These parts offer strength, resistance to corrosion, and can handle heat well. They help cars last longer and perform better.

In the marine world, they are used for propeller shafts, valve bodies, and fittings. Their ability to resist saltwater corrosion makes them great for sea equipment.

| Industry | Stainless Steel Investment Casting Applications |

|---|---|

| Aerospace | Engine parts, landing gear, structural elements |

| Medical | Surgical instruments, implants, specialized equipment |

| Automotive | Engine parts, suspension systems, exhaust systems |

| Marine | Propeller shafts, valve bodies, fittings |

This list shows how versatile and important stainless steel investment castings are. They play a big role in many industries, making modern manufacturing possible.

Case Study: Delivering Excellence in Stainless Steel Investment Casting

At KT-Foundry, we're proud of our work on tough projects. We deliver top-notch custom stainless steel castings. A recent project shows our focus on precision casting and our commitment to quality.

A major medical device maker came to us with a big challenge. They needed a key part for a new surgical tool, and it had to be perfect. The part's complex design and tight tolerances made it ideal for investment casting.

- We worked closely with the client to get all the project details right. This included material specs, size tolerances, and surface finish.

- Our team used our custom stainless steel casting skills to create a special process for the project.

- We kept a close eye on quality throughout the making process. This ensured every part was up to precision casting and quality stainless steel castings standards.

| Requirement | KT-Foundry Solution |

|---|---|

| Material | Custom 316L stainless steel |

| Tolerance | ±0.025 mm |

| Surface Finish | Ra ≤ 0.4 μm |

The outcome was a huge success. Our client was very happy with the custom stainless steel parts. They met all the client's needs. Our efficient process and focus on quality helped us deliver on time and within budget. This made us a trusted partner in the medical device field.

"KT-Foundry's attention to detail and their ability to overcome challenges during the production process were instrumental in the success of our project. We are confident in their capability to deliver quality stainless steel castings for our future needs."

This case study shows our wide range of stainless steel investment casting skills. It also shows our dedication to giving our clients the best products and services. When you work with KT-Foundry, you get unmatched precision casting and top-quality stainless steel castings.

Why KT-FOUNDRY for Stainless Steel Investment Casting?

KT-FOUNDRY is a top choice for businesses needing premium stainless steel investment casting. Our advanced facilities and expert team make us the best for stainless steel investment casting companies, casting services, and manufacturers. We focus on precision and durability.

We are committed to quality at KT-FOUNDRY. Our quality control is strict, with thorough inspections and tests. This ensures every stainless steel part we make is top-notch. Our quality focus sets us apart, delivering great results for our clients.

| Key Advantages | KT-FOUNDRY | Industry Average |

|---|---|---|

| Dimensional Accuracy | ±0.05% | ±0.1% |

| Surface Finish | 16-20 Ra | 20-32 Ra |

| Mechanical Properties | Tensile Strength: 100-150 ksi | Tensile Strength: 80-120 ksi |

We care about the journey as much as the final product. We offer personalized support and guidance in the stainless steel investment casting process. We aim for a great experience, from design to delivery.

Looking for precision components for your equipment, medical devices, or aerospace needs? KT-FOUNDRY is your reliable partner. Our focus on innovation, quality, and customer satisfaction is unmatched. Partner with us for a difference in your business.

Conclusion

In our guide, we've looked into stainless steel investment casting. We've covered the process, the different stainless steel grades, and its many benefits. This technology is key for making precise parts.

Stainless steel is strong and resistant to corrosion. Investment casting gives parts a great finish and exact dimensions. This makes it vital for today's engineering and manufacturing.

We've shown KT-Foundry's skill in stainless steel investment casting. As a top company, we have the know-how, tools, and success stories to back us up. We can handle your needs for medical devices, aerospace parts, or industrial equipment.

Thinking about your next project? Look into stainless steel investment casting. Working with KT-Foundry means getting top-notch quality and reliability. Contact us to improve your manufacturing and product performance.

FAQs

What is stainless steel investment casting and how does it work?

Stainless steel investment casting is a manufacturing process used to create intricate and precision parts from stainless steel alloys. The process begins with a wax pattern coated in a ceramic shell. Once the shell hardens, the wax is melted away, leaving a cavity in the shape of the desired part. Molten stainless steel is then poured into this cavity. After cooling, the ceramic shell is removed, resulting in a cast stainless steel component. This method allows for high dimensional accuracy and a superior surface finish.

What are the key benefits of using stainless steel investment casting?

There are numerous advantages of stainless steel investment casting, including high precision, the ability to create complex shapes, and excellent corrosion resistance. Components made through this process typically require minimal machining due to their fine tolerances. Additionally, stainless steel investment casting can produce parts with a high-quality surface finish, making it ideal for applications where aesthetics and performance are critical.

What types of stainless steel are used in investment casting?

The most commonly used stainless steels in investment casting include 304 stainless steel, 316 stainless steel, and duplex stainless steel. Each type offers unique properties; for example, 304 stainless steel is known for its excellent corrosion resistance and formability, while 316 stainless steel provides enhanced resistance to pitting and crevice corrosion. Martensitic stainless steel is also utilized for applications requiring higher strength and hardness.

What is the investment casting process for stainless steel?

The investment casting process for stainless steel involves several steps: creating a wax pattern, building a ceramic shell around the pattern, melting the wax out, pouring molten stainless steel into the shell, and finally, removing the shell to retrieve the cast parts. Each step is crucial for ensuring the final product meets the desired specifications and standards.

How does corrosion resistance impact the choice of stainless steel alloys?

Corrosion resistance is a critical factor