Pump impellers play a crucial role in various industrial applications, where fluid handling is essential. An impeller is a rotating component equipped within a pump, engineered to transfer energy from the motor that drives the pump to the fluid being pumped by accelerating the fluid outwards from the center of rotation. This article will delve into the intricacies of pump impellers, their casting processes, types, and applications, highlighting why quality impellers are indispensable for efficient industrial operations.

Understanding Pump Impellers and Their Manufacturing

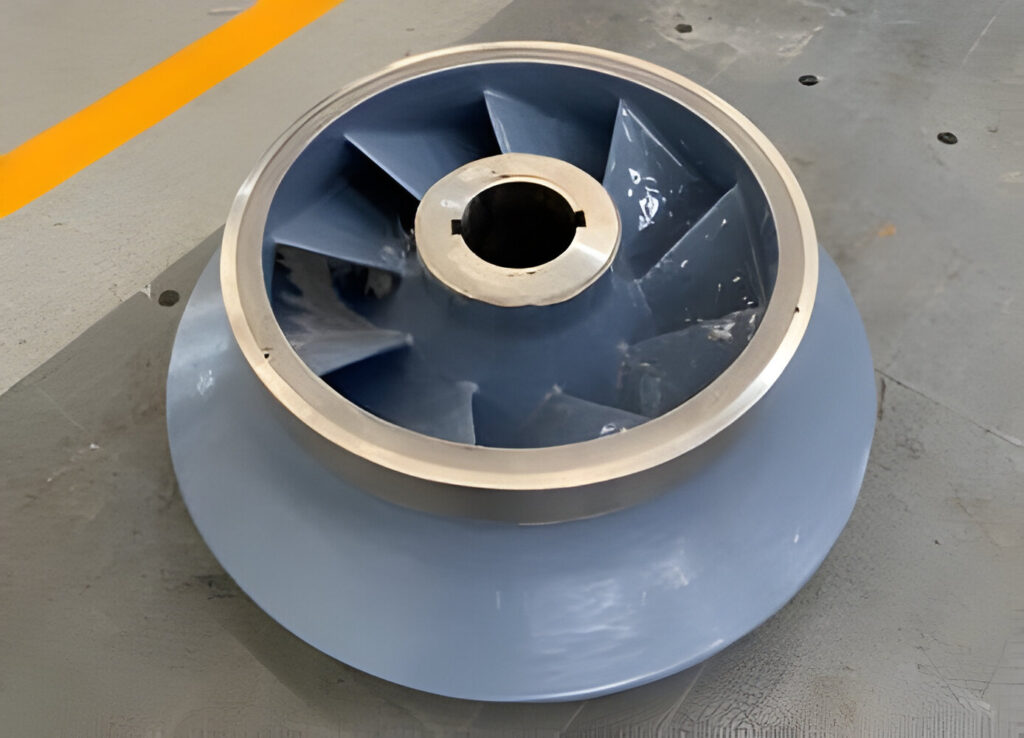

Pump impellers are typically made through a process known as impeller casting. This involves pouring molten metal into a mold corresponding to the desired shape of the impeller. The choice of material for casting impellers largely depends on the application, but cast iron impellers are particularly favored for their durability and efficiency. Cast iron pump impellers offer excellent wear resistance and are capable of handling high flow rates, making them ideal for water pumps and other heavy-duty applications.

Impeller casting manufacturers employ various alloys to enhance the properties of the final product. For instance, adding elements like chromium or nickel can improve the corrosion resistance of the impellers, which is crucial for operations involving aggressive fluids.

Product Spotlight: High-Performance Pump Impellers

At KT Foundry, we specialize in the design and manufacture of high-quality pump impellers that cater to a wide range of applications. Our products include:

- Water Pump Impellers: Designed for both residential and industrial water pumps, these impellers are optimized for minimal hydraulic loss and maximum efficiency.

- Cast Iron Pump Impellers: Ideal for heavy-duty applications, our cast iron impellers are robust, corrosion-resistant, and capable of handling large volumes of fluids under high pressure.

- Custom Impeller Solutions: We also provide custom impeller casting services to meet specific operational requirements, ensuring that all our clients receive impellers that perfectly match their systems.

Practical Applications of Pump Impellers

Pump impellers are used in a myriad of applications across industries:

- Water Treatment Plants: Impellers are pivotal in the movement of large volumes of water through treatment facilities, ensuring efficient water purification and distribution.

- Chemical Processing: Specialty impellers made from corrosion-resistant alloys are used in the chemical industry to handle aggressive substances without degradation.

- HVAC Systems: In heating, ventilation, and air conditioning systems, impellers are used to circulate air and coolants to maintain the desired environmental conditions.

- Agricultural Irrigation: Impellers enable the high-capacity pumping required for modern irrigation systems, facilitating efficient water management in agricultural fields.

Why Choose KT Foundry for Your Pump Impeller Needs?

At KT Foundry, we pride ourselves on our expert craftsmanship and the technical excellence of our products. Our impellers are not only crafted using state-of-the-art casting techniques but are also rigorously tested to ensure reliability and performance. We understand the critical role our impellers play in your operations, which is why we offer tailored solutions and responsive customer support.

Interested parties are encouraged to visit our website at kt-foundry to explore our range of impeller products and discover how our solutions can enhance your operational efficiency. For further inquiries or to discuss a custom impeller casting project, please contact us directly through our website.

We look forward to contributing to the success of your projects with our top-of-the-line impellers.