Weld table clamps are an indispensable tool in any metalworking or welding environment, offering the necessary stability and precision for a wide range of projects. As the demand for efficient and reliable welding accessories continues to grow, understanding the variety and functionality of weld table clamps can significantly enhance your workshop’s productivity.

What Are Weld Table Clamps?

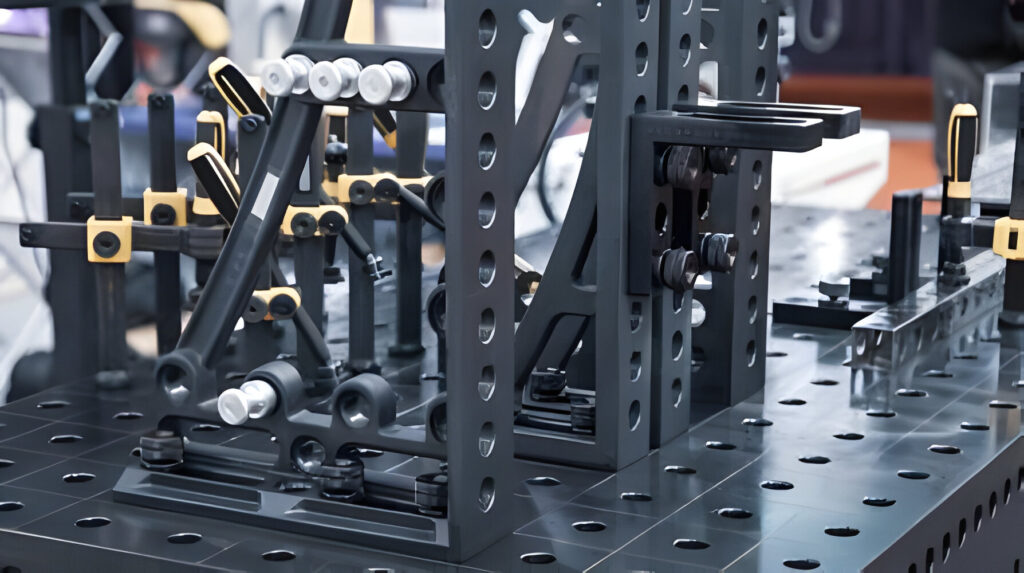

Weld table clamps are designed to hold workpieces securely on a welding table. These clamps are engineered to provide strong, stable, and adjustable holding forces, which are critical in achieving high-quality welds. They come in various sizes and types, each tailored to different specifications and requirements of welding tasks.

Types of Weld Table Clamps

- 16mm Welding Table Clamps: These clamps are ideal for heavy-duty applications, capable of holding large and heavy components with ease. The 16mm refers to the diameter of the bolt used in the clamp, which is robust enough for substantial workpieces.

- 5/8 Welding Table Clamps: Often listed as 5/8 inch, these clamps are versatile and suitable for both light and medium welding tasks. Their size makes them a perfect fit for standard welding tables with 5/8 inch holes, ensuring a secure fit and excellent stability.

- Magnetic Welding Table Clamps: These are particularly useful in scenarios where traditional clamping methods might not be feasible. Magnetic clamps allow for rapid positioning and adjustment, which can significantly speed up the setup process and increase overall workflow efficiency.

How Do Welding Table Clamps Work? Welding table clamps operate by attaching directly to the table through specific holes known as the welding table clamp hole size. This system allows for adjustments and alignments to be made quickly, ensuring that the workpiece remains immobile during the welding process. The effectiveness of a welding clamp depends significantly on its compatibility with the table’s hole size and configuration.

Applications and Scenarios Weld table clamps are used in a variety of settings, from industrial manufacturing to small private workshops. They are particularly crucial in scenarios where precision is paramount, such as in automotive assembly, aerospace component fabrication, and artistic metal work. The ability to maintain the position of a workpiece during the intense welding process not only enhances safety but also improves the quality of the final product.

FAQs About Weld Table Clamps

- Q: Can I use a 16mm clamp on a table designed for 5/8 inch clamps? A: It is essential to use clamps that match the hole size of your welding table to ensure stability and safety.

- Q: Are magnetic clamps suitable for all types of welding tables? A: Magnetic clamps are best used on ferromagnetic surfaces. If your table is non-magnetic, traditional bolt-down clamps would be more appropriate.

- Q: How do I maintain my weld table clamps? A: Regular cleaning and occasional lubrication of the moving parts will extend the life and performance of your clamps.

Contact Us

For more information on our range of weld table clamps or to find the perfect clamp for your needs, visit us at kt-foundry. Our experts are ready to assist you in selecting the right tools to enhance your welding accuracy and efficiency.