Harnessing Tradition and Precision: The Impeller Sand Casting Process

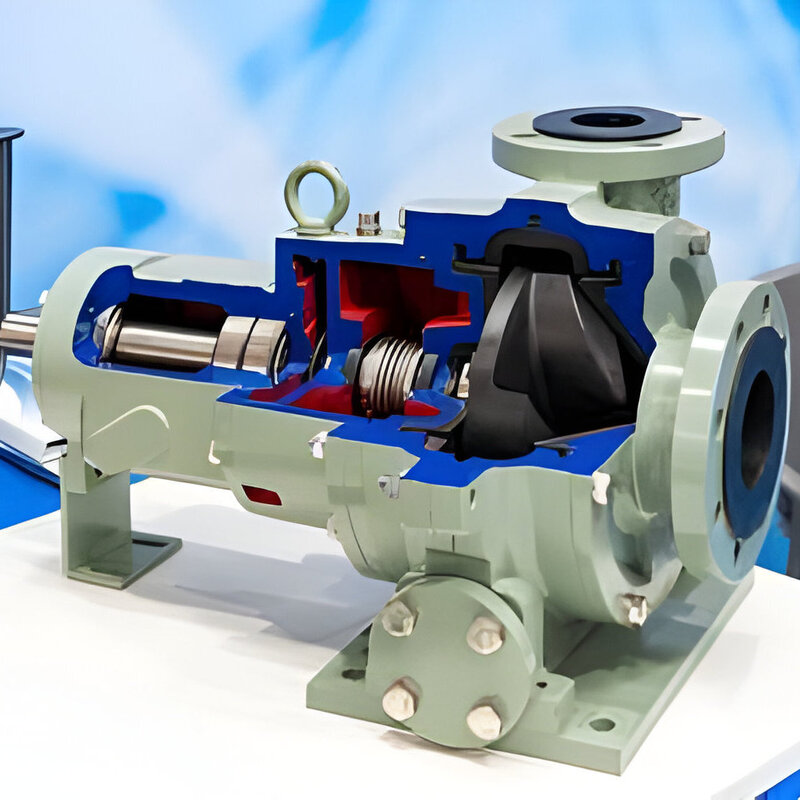

In the realm of pump manufacturing, impellers are the heart of centrifugal pumps, playing a vital role in fluid transfer applications. Among the various methods of impeller production, sand casting stands as a time-honored technique renowned for its versatility and cost-effectiveness. Let's explore the intricacies of impeller sand casting and its significance in producing reliable pump components.

The Art of Impeller Sand Casting

Impeller sand casting involves the use of molds made from compacted sand to create intricate impeller shapes. This method allows for the production of impellers with complex geometries and internal passages, making it suitable for a wide range of pump applications. The process begins with the creation of a pattern that defines the shape of the impeller. This pattern is then used to create a mold cavity in sand, into which molten metal is poured to form the final component.

At KT Foundry, we specialize in impeller sand casting, utilizing advanced molding techniques and high-quality materials to ensure the precise replication of impeller designs. Our skilled craftsmen meticulously craft each mold to exact specifications, resulting in impellers that meet the highest standards of quality and performance.

Advantages of Impeller Sand Casting

Impeller sand casting offers several advantages over other manufacturing methods, particularly for larger and more complex components. Firstly, sand casting allows for the production of impellers with thick walls and robust structures, making them suitable for heavy-duty applications such as industrial pumps.

Additionally, sand casting is a cost-effective solution for low to medium volume production runs, making it ideal for custom and specialized impeller designs. The versatility of sand casting also enables the incorporation of various alloys, including cast iron, bronze, and stainless steel, to meet specific performance requirements.

Elevating Pump Performance with Sand Cast Impellers

Impeller sand casting plays a crucial role in enhancing the performance and reliability of pump systems across various industries. Whether it's centrifugal pump impellers for water treatment facilities or boat water pump impellers for marine applications, the quality and precision of sand cast impellers are paramount.

By partnering with KT Foundry for impeller sand casting solutions, businesses can access high-quality components designed to withstand the rigors of demanding operating conditions. Our expertise in sand casting technology ensures that each impeller meets strict dimensional tolerances and material specifications, resulting in optimal pump performance and longevity.

Choosing a Trusted Impeller Sand Casting Supplier

When selecting an impeller sand casting supplier, it's essential to choose a trusted partner with a proven track record of excellence. At KT Foundry, we are committed to delivering superior quality impellers that meet the unique needs of our clients.

From initial design consultation to final production, our team of experts works closely with customers to ensure that every impeller meets their exact specifications and performance requirements. With our state-of-the-art facilities and dedication to precision manufacturing, we guarantee exceptional results that elevate pump performance and reliability.

Conclusion: Elevating Pump Efficiency with Impeller Sand Casting

In conclusion, impeller sand casting remains a cornerstone of pump manufacturing, offering unparalleled versatility, cost-effectiveness, and reliability. By leveraging the expertise of trusted suppliers like KT Foundry, businesses can access high-quality impellers designed to optimize pump performance and durability.

Contact us today to learn more about our impeller sand casting capabilities and discover how we can help elevate the efficiency and reliability of your pump systems.