In the realm of pump manufacturing, where durability, reliability, and efficiency are paramount, the significance of each component cannot be overstated. Among the myriad of materials available, cast iron stands out for its remarkable properties, making it the go-to choice for crafting enduring pump parts. Within this domain lies a niche expertise: casting dredge pump parts. Let's delve into the craftsmanship and offerings of a premier manufacturer in this field.

Crafting Endurance: The Art of Cast Iron Pump Parts

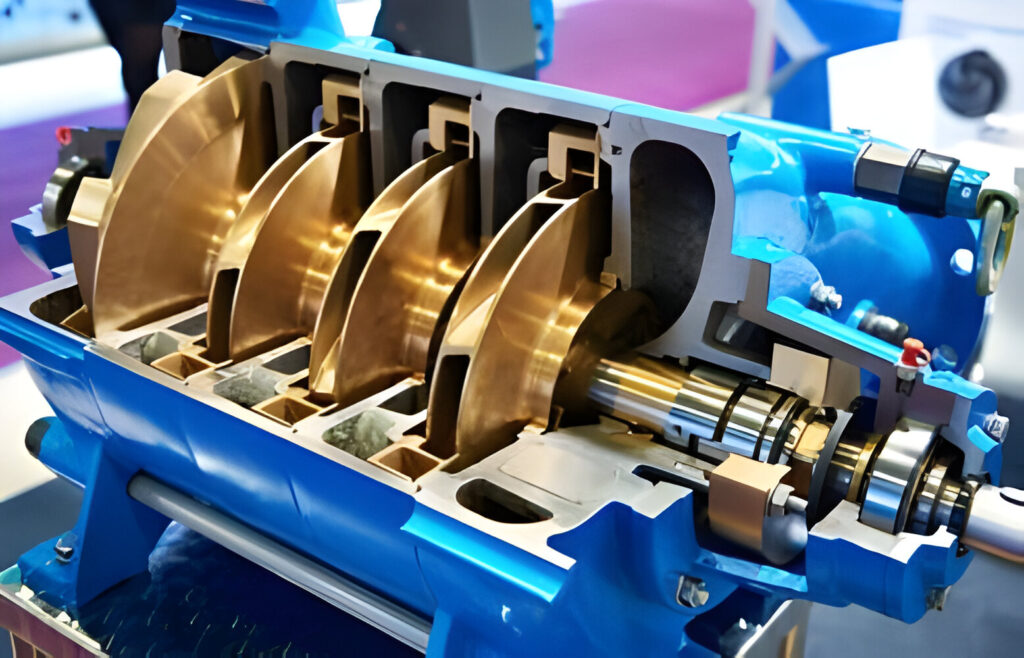

Cast iron, known for its exceptional strength and resistance to corrosion, has been a cornerstone in pump manufacturing for centuries. From antique hand water pump parts to modern submersible pump casting parts, the versatility of cast iron knows no bounds. Its ability to withstand harsh conditions, high pressures, and abrasive materials makes it indispensable in various industries, particularly in dredging operations.

At the heart of every efficient pump lies its parts, meticulously crafted to perform under demanding conditions. Whether it's cast iron hand pump parts for shallow wells or deep well hand pump parts designed for accessing groundwater from greater depths, precision in manufacturing is non-negotiable. Pump casting manufacturers employ advanced techniques to ensure each component meets exacting standards, guaranteeing longevity and reliability in operation.

Unveiling Specialization: Casting Dredge Pump Parts

Within the realm of pump manufacturing, specialization is key to meeting the unique needs of different industries. Dredging, a crucial operation in marine construction, mining, and environmental remediation, requires pumps tailored to handle abrasive slurry with efficiency and durability. This is where casting dredge pump parts take center stage.

Manufacturing casting dredge pump parts demands not only expertise but also a deep understanding of the challenges posed by dredging operations. From china casting slurry pump parts to casting dredge pump parts, every component undergoes rigorous testing to ensure optimal performance in the harshest of environments. These parts are engineered to withstand abrasion, erosion, and corrosion, ensuring uninterrupted operation even in the most demanding conditions.

Excellence in Engineering: Quality Pump Casting Parts

In the pursuit of excellence, every detail matters. Pump casting parts embody the culmination of advanced engineering and craftsmanship, meticulously designed to meet the diverse needs of industries worldwide. Whether it's a pitcher pump base for domestic water supply or specialized submersible pump casting parts for industrial applications, quality is non-negotiable.

A reputable manufacturer like kt-foundry takes pride in its commitment to delivering top-notch pump casting parts that exceed customer expectations. With a comprehensive range of products, including cast iron water pump parts and pitcher pump rebuild kits, they cater to a diverse clientele spanning across industries. Moreover, their expertise in casting slurry pump parts and dredge pump components positions them as a trusted partner in critical operations where reliability is paramount.

Elevating Performance with Quality Pump Parts

In the dynamic landscape of pump manufacturing, the choice of materials and craftsmanship plays a pivotal role in determining performance and reliability. Cast iron pump parts, renowned for their durability and resilience, continue to be the preferred choice for industries worldwide. Whether it's casting dredge pump parts or crafting intricate submersible pump components, precision engineering sets the stage for unparalleled performance.

As industries evolve and challenges become more complex, the demand for quality pump casting parts remains unwavering. For those seeking excellence in craftsmanship and reliability in operation, partnering with a trusted manufacturer like kt-foundry ensures access to premium pump components that stand the test of time.