Impellers serve as the beating heart of pumps, dictating their efficiency and reliability in various applications. In recent years, the utilization of machined cast impellers has emerged as a hallmark of precision engineering, offering unparalleled performance across industries. Let's delve into the realm of machined cast impellers, exploring their manufacturing processes, applications, and advantages.

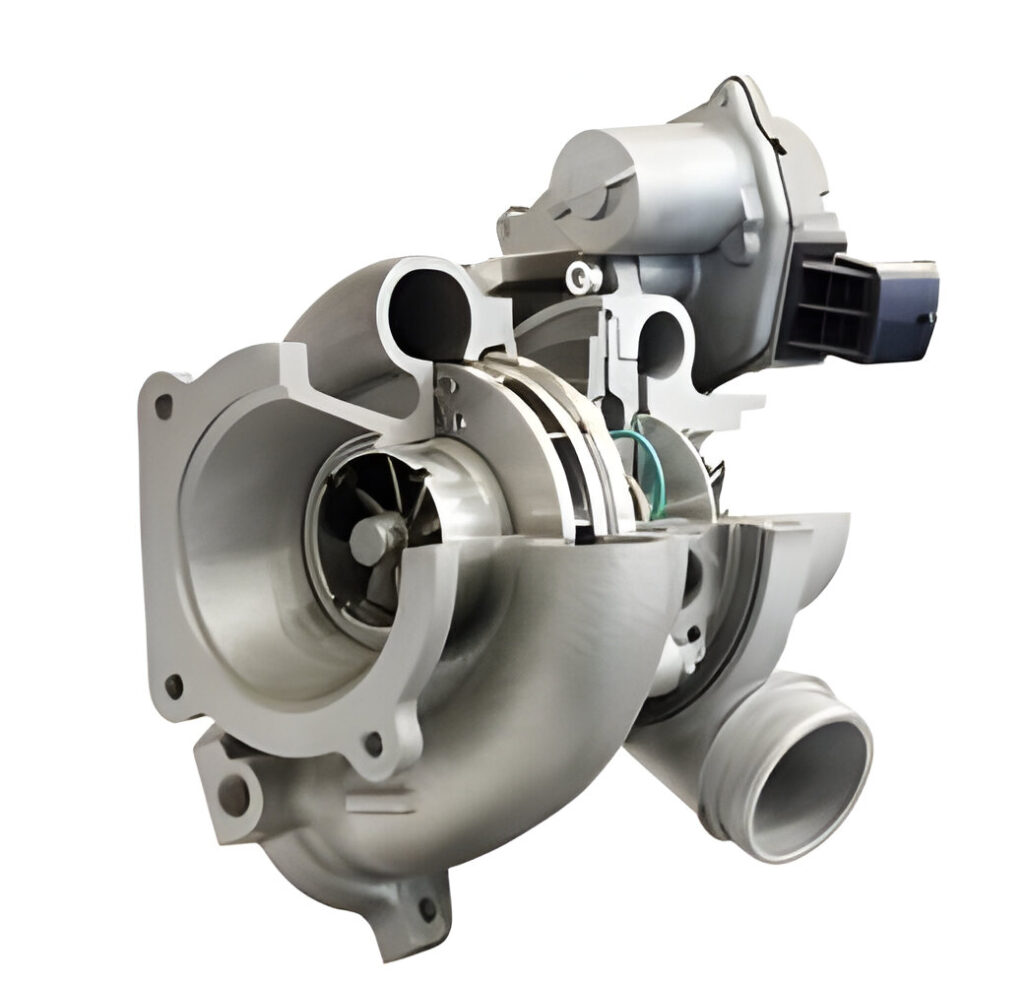

Machined cast impellers encompass a fusion of advanced machining techniques with the versatility of casting methodologies. Among the myriad of casting techniques, investment casting stands out for its ability to produce intricate geometries with exceptional detail and surface finish. This process involves creating wax patterns, coating them with ceramic shell, melting out the wax, and pouring molten metal into the cavity. The resulting impeller undergoes meticulous machining to achieve precise dimensions, ensuring optimal pump performance.

Fuel pump impellers, vital components in automotive and industrial fuel delivery systems, benefit greatly from machined cast technology. These impellers are subjected to rigorous conditions, necessitating materials like stainless steel or specialized alloys for enhanced durability and corrosion resistance. Machined cast fuel pump impellers excel in delivering consistent fuel flow, contributing to engine efficiency and longevity.

Centrifugal pump impellers, the workhorses of fluid transfer and circulation systems, also reap the rewards of machined cast technology. Whether it's a single-stage or multi-stage centrifugal pump, impeller design plays a pivotal role in achieving desired flow rates and pressure levels. Machined cast centrifugal pump impellers offer customizable configurations tailored to specific application requirements, ensuring optimal fluid dynamics and energy efficiency.

Marine applications demand impellers capable of withstanding corrosive seawater and harsh environments. Boat water pump impellers crafted through machined cast processes, often from materials like bronze or stainless steel, exhibit superior corrosion resistance and longevity. These impellers ensure efficient coolant circulation or bilge pumping, crucial for marine vessel operation and safety.

OEMs seeking reliable components for machinery and equipment turn to machined cast impellers for consistent quality and performance. Well-casted impellers manufactured to OEM specifications undergo stringent quality control measures, guaranteeing adherence to tight tolerances and material standards. Whether it's sand casting or investment casting, the versatility of machined cast processes accommodates diverse OEM requirements across industries.

The choice between bronze and cast iron impellers hinges on specific application needs and environmental factors. Bronze impellers excel in corrosive environments, making them ideal for marine and chemical processing applications. In contrast, cast iron impellers offer robustness and cost-effectiveness, suitable for handling abrasive fluids in industrial settings.

Understanding the mechanics of impeller pumps is essential for optimizing system performance and efficiency. Impeller pumps operate on the principle of centrifugal force, wherein rotating blades accelerate fluid outward, creating a low-pressure zone that draws more fluid into the pump. The design intricacies of impellers, including blade profile, diameter, and pitch, influence pump characteristics such as flow rate and head pressure.

In conclusion, machined cast impellers epitomize precision engineering, offering unmatched performance and reliability across diverse applications. From fuel delivery systems to marine propulsion, these meticulously crafted components redefine pump efficiency and longevity. For customers seeking superior quality impellers, KT-Foundry provides a comprehensive range of machined cast solutions tailored to specific requirements. Contact us today to elevate your pumping systems to new heights of performance and durability.