In the vast domain of industrial and residential pumping systems, the booster pump impeller stands as a pivotal component, orchestrating the flow and efficiency of fluid management. This intricate part, often crafted through meticulous impeller casting processes, plays a critical role in enhancing the dynamic performance and longevity of pumps. At KT Foundry, we specialize in the design, manufacture, and distribution of high-quality cast iron impeller products, tailoring solutions to meet diverse application needs.

Understanding Booster Pump Impellers

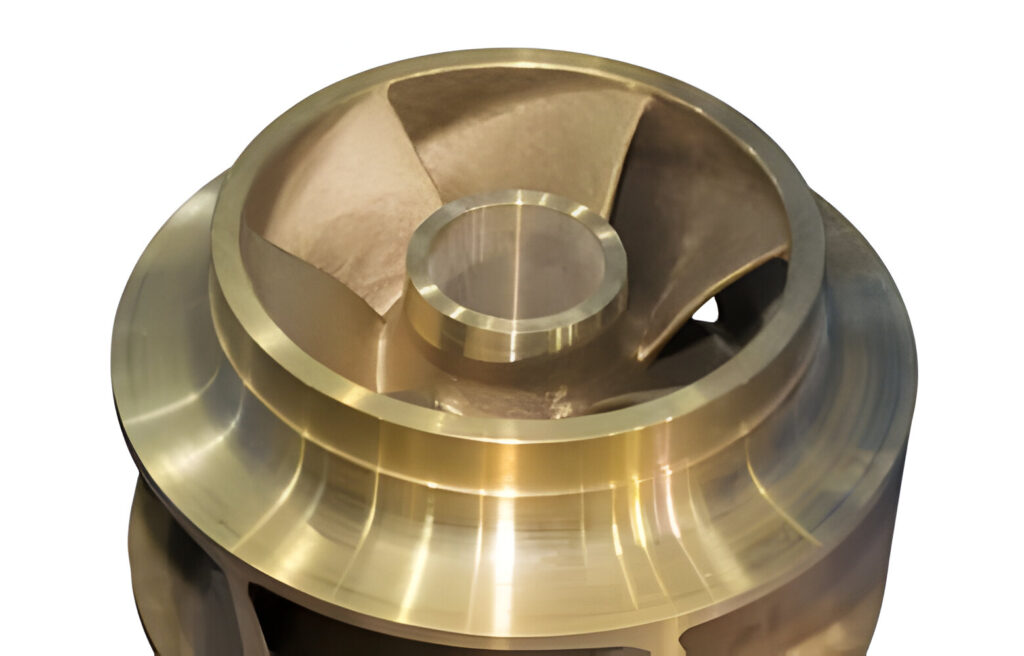

A booster pump impeller is designed to increase the pressure and flow of a fluid. These impellers are central to the operation of water pumps, circulating the fluid through the system with enhanced velocity and efficiency. The choice of material and design specifics are crucial for ensuring optimal performance and durability. Cast iron, known for its excellent wear resistance and robustness, is a preferred material for manufacturing these components, especially in scenarios demanding high strength and extended operational life.

The Excellence in Impeller Castings

At KT Foundry, our impeller castings are engineered with precision to ensure flawless functionality and peak performance. We employ advanced casting techniques to produce pump impellers that not only meet but exceed industry standards. Our product range includes everything from water pump impellers to more specialized cast iron pump impellers, each tailored to specific operational requirements.

Manufacturing Process

The manufacturing of pump impellers at KT Foundry involves sophisticated casting methods, which ensure the structural integrity and hydraulic efficiency of the impellers. We use high-grade cast iron to forge impellers that provide improved corrosion resistance and decreased susceptibility to wear and tear. This process ensures that each impeller delivers consistent performance, even under the most rigorous conditions.

Applications and Scenarios

Our cast iron pump impellers are versatile and find applications across various sectors. These include water treatment facilities, HVAC systems in commercial buildings, agricultural irrigation, and even in domestic water supply systems. The robust design of our impellers makes them ideal for these applications, where reliability and efficiency are paramount.

FAQs

Q: How long do cast iron impellers last?

A: With proper maintenance, cast iron impellers can operate effectively for many years, thanks to their inherent durability and resistance to wear.

Q: Can impellers be custom-made for specific applications?

A: Yes, at KT Foundry, we offer customization options based on the specific requirements of your system's performance and application scenario.

Q: How do I choose the right impeller for my system?

A: Our expert team is ready to assist you in selecting the most appropriate impeller based on your system’s specifications and operational needs.

Connect with KT Foundry

For those who are seeking unparalleled efficiency and durability in pumping systems, exploring the range of booster pump impellers at KT Foundry is a must. Whether you are involved in industrial engineering, water management, or any field requiring reliable pumping solutions, our team is ready to assist you. Visit our website at kt-foundry to learn more about our products and how we can help enhance your systems. Don’t hesitate to contact us for detailed product information, bespoke solutions, and expert advice. Your next step towards optimizing your pumping operations is just a few clicks away.