Introduction to Spheroidal Graphite Iron

Spheroidal Graphite Iron, also known as SG Iron, is a special engineering material. It has a unique nodular graphite structure. This structure prevents cracks and boosts the material's flexibility.

Key Features and Benefits

SG Iron has many great qualities. It has high tensile strength, is very ductile, and resists fatigue well. These benefits come from adding magnesium and cerium to the iron. These elements help create the spheroidal graphite structure.

Physical and mechanical properties of 4 common ductile iron

| ASTM A536 Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HBW) | Density (g/cm) | Modulus of Elasticity (GPa) |

| Grade 60-40-18 | 415 | 275 | 18 | 130-170 | 7.1 | 165 |

| Grade 65-45-12 | 450 | 310 | 12 | 140-190 | 7.1 | 170 |

| Grade 80-55-06 | 550 | 380 | 6 | 160-210 | 7.1 | 175 |

| Grade 70-50-05 | 485 | 345 | 5 | 150-200 | 7.1 | 170 |

| Grade 100-70-03 | 700 | 480 | 3 | 190-250 | 7.1 | 180 |

Table Explanation

- Tensile Strength: Maximum stress material can withstand while being pulled before failure.

- Yield Strength: Stress level where the material begins to deform plastically.

- Elongation: Material’s ability to elongate before breaking, represented as a percentage.

- Hardness: Brinell hardness (HBW), indicates wear resistance.

- Density: Average density of ductile iron.

- Modulus of Elasticity: Material's ability to deform elastically when force is applied, indicating stiffness.

Understanding SG Iron Material and Its Formation

Spheroidal Graphite (SG) iron, also known as ductile iron, is a unique cast iron material. It stands out because of its special graphite formation. This material is made by treating molten cast iron with nodulizing elements, mainly magnesium or cerium.

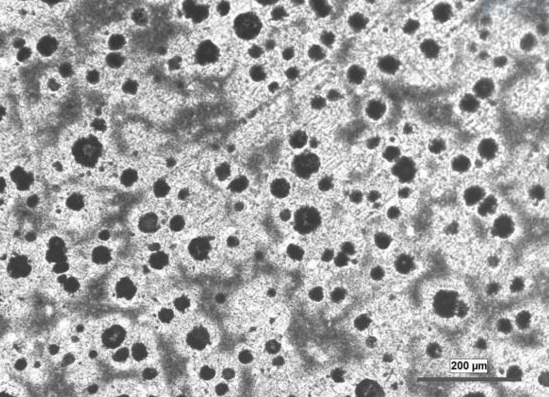

This treatment causes the graphite to form as nodules or spherulites. Unlike traditional grey iron, which has flakes, SG iron has spheroidal graphite nodules.

The spheroidal shape of the graphite nodules is crucial. It reduces stress points in the metal, boosting its ductility and strength. This makes SG iron perfect for many industrial uses.

The nodulizing elements used in making SG iron are key. Magnesium is the most common, helping to change graphite into spherical shapes. This process, called nodular graphite formation, is what makes SG iron special.

"The spheroidal shape of the graphite nodules is the key to SG iron's enhanced properties, reducing stress concentration points within the metal matrix and improving overall ductility and strength."

Understanding how nodular graphite formation works helps us see why SG iron is so valuable. It shows how magnesium treatment and other nodulizing elements give SG iron its unique qualities.

"The unique properties of SG iron, including its high tensile strength, yield strength, and elongation, make it a preferred choice for a wide range of engineering applications."

Microstructure and Nodular Formation

Ductile iron, also known as spheroidal graphite (SG) iron, has a special microstructure. It's made of graphite nodules in a metal matrix. This matrix can be ferrite, pearlite, or austenite, depending on the needs and process used.

The casting process and adding magnesium or cerium create these nodules. Their size, shape, and how they're spread out affect the material's strength, ductility, and impact resistance. Learn more about these properties.

Using advanced techniques like austempering can make ductile iron even better. This heat treatment changes the metal matrix. It creates a mix of ferrite and austenite, improving strength and toughness.

| Microstructural Feature | Influence on Properties |

|---|---|

| Graphite Nodules | Enhance toughness and inhibit crack propagation |

| Ferrite Matrix | Improve ductility and machinability |

| Pearlitic Matrix | Increase strength and hardness |

| Austenitic Matrix | Provide exceptional wear resistance and toughness |

By controlling the microstructure, makers can adjust ductile iron's properties. This is useful for many industries, from cars to heavy machinery.

"The unique microstructure of ductile iron is the key to its superior mechanical properties and widespread industrial applications."

Different Grades and International Standards

| Country | Standard | SG Iron Grades (Spheroidal Graphite Cast Iron) | ||||||

| ISO | ISO 1083 | 400-15 | 450-10 | 500-7 | 600-3 | 700-2 | 800-2 | 900-2 |

| 400-18 | ||||||||

| China | GB 1348 | QT400-18 | QT450-10 | QT500-7 | QT600-3 | QT700-2 | QT800-2 | QT900-2 |

| USA | ASTM A536 | 60-40-18 | 60-42-10 | 70-50-05 | 80-55-06 | 100-70-03 | 120-90-02 | - |

| 65-45-12 | 80-60-03 | |||||||

| Germany | DIN 1693 | GGG40 | - | GGG50 | GGG60 | GGG70 | GGG80 | - |

| Austria | ||||||||

| European | EN 1563 | EN-GJS-400-15 | EN-GJS-450-10 | EN-GJS-500-7 | EN-GJS-600-3 | EN-GJS-700-2 | EN-GJS-800-2 | EN-GJS-900-2 |

| EN-GJS-400-18 | ||||||||

| Japan | JIS G5502 | FCD400 | FCD450 | FCD500 | FCD600 | FCD700 | FCD800 | - |

| Italy | UNI 4544 | GS370-17 | GS400-12 | GS500-7 | GS600-2 | GS700-2 | GS800-2 | - |

| France | NF A32-201 | FGS370-17 | FGS400-12 | FGS500-7 | FGS600-2 | FGS700-2 | FGS800-2 | - |

| UK | BS 2789 | 400/17 | 420/12 | 500/7 | 600/7 | 700/2 | 800/2 | 900/2 |

| India | IS 1865 | SG370/17 | SG400/12 | SG500/7 | SG600/3 | SG700/2 | SG800/2 | - |

| Spain | UNF | FGE38-17 | FGE42-12 | FGE50-7 | FGE60-2 | FGE70-2 | FGE80-2 | - |

| Belgium | NBN 830-02 | FNG38-17 | FNG42-12 | FNG50-7 | FNG60-2 | FNG70-2 | FNG80-2 | - |

| Australia | AS 1831 | 300-17 | - | 500-7 | 600-3 | 700-2 | 800-2 | - |

| 400-12 | ||||||||

| Sweden | SS 14 07 | 0717-02 | - | 0727-02 | 0732-03 | 0737-01 | 0864-03 | - |

| Norway | NS11 301 | SJK-400.3 | - | SJK-500 | SJK-600 | SJK-700 | SJK-800 | |

| SJK-400 | ||||||||

Manufacturing Process and Quality Control

The making of spheroidal graphite (SG) iron is a detailed process. It starts with melting raw materials. Then, special elements like magnesium or cerium are added to change the graphite into a round shape.

After that, the metal is treated with tiny amounts of alloys for better quality. The last step is casting, where the molten SG iron is shaped into the desired form.

Quality checks are done at every step. Spectrographic analysis checks the chemical makeup. Metallographic examination looks at the structure to make sure the graphite is round. Mechnical testing checks the strength and flexibility of the material.

To make sure the castings are perfect, non-destructive testing is used. This includes ultrasonic and radiographic inspections. These methods find any problems inside without damaging the product.

For certain uses, heat treatment processes are applied. These can include normalizing, annealing, or austempering. They help improve the material's properties and performance.

The whole process, from making to testing, ensures SG iron castings are top-notch. They are strong, flexible, and wear-resistant. This makes them a great choice for many industrial needs.

Industrial Applications and Use Cases

Spheroidal Graphite (SG) Iron, also known as ductile iron, is used in many industries. It's known for its great properties and flexibility. This material is used in cars, buildings, and more, showing its wide range of uses.

Automotive Industry Applications

In the car world, SG Iron is key for important parts. It's strong, flexible, and resists wear well. This makes it perfect for things like crankshafts and suspension parts.

It can handle a lot of stress and impacts. This ensures cars are safe and reliable.

Construction and Infrastructure

In building and infrastructure, SG Iron is a big help. It's used for pipes, manhole covers, and bridge parts. Its durability, resistance to corrosion, and easy to make nature are big pluses.

It can handle tough weather and heavy loads. This makes it crucial for building strong, lasting structures.

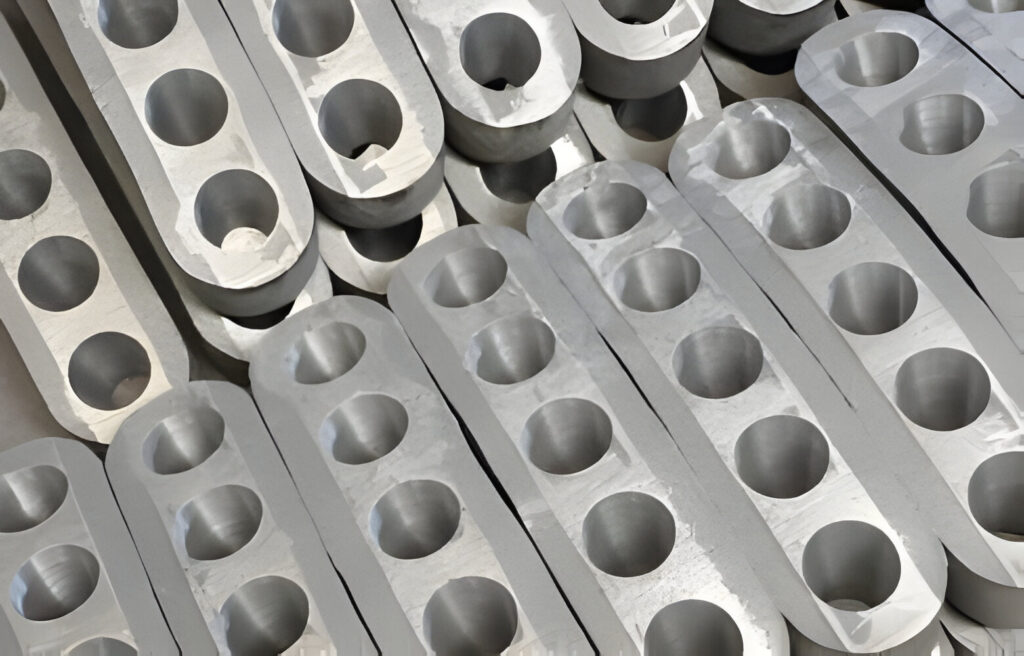

Heavy Machinery Components

SG Iron is also great for heavy machinery parts. It's strong, resists wear, and easy to work with. This makes it perfect for gears, housings, and hydraulic parts in big machines.

It's also good for absorbing vibrations and impacts. This is why it's used in musical instruments like piano harps.

SG Iron is not just for cars, buildings, and machines. It's also used in wind power for hubs and parts. This helps grow and support renewable energy.

"SG Iron's exceptional properties and versatility make it an indispensable material in numerous industrial applications, from automotive to construction and heavy machinery."

Custom Casting Services

At KT-FOUNDRY, we specialize in custom casting services for SG Iron components. We handle a variety of sizes and grades, from small parts to big industrial castings. Our goal is to provide solutions that fit your specific needs, ensuring your components last long and work well.

Our advanced facilities and strict quality checks mean our castings meet high standards. If you need custom parts or replacements, our team will help. We work with you to find the best solution for your challenges.

SG Iron is known for its strength, resistance to corrosion, and versatility. We use these properties to make castings that beat traditional materials in many areas. From cars to construction and heavy machinery, our custom castings offer top performance and reliability. This helps your operations run smoothly and efficiently.