Aluminum is a common non-ferrous metal, but it doesn't rust like iron or steel. Instead, it corrodes. Knowing the difference between rust and corrosion helps us understand how aluminum reacts to its environment.

Aluminum is found in large amounts in the earth's crust. It's used in many industries because it's affordable and versatile. When exposed to air and moisture, aluminum forms a protective oxide layer. This layer protects the metal from further damage.

The Fundamental Difference Between Rust and Corrosion

It's key to know the difference between rust and corrosion when talking about metal damage. Rust is a kind of corrosion that happens to iron-based metals like steel. Corrosion is a wider term for how metals break down through chemical reactions.

Rust makes metal flake off, showing more metal to get oxidized. But, aluminum corrosion creates a protective layer that stops more damage. Knowing this helps us understand how metals react to their surroundings.

Metals like iron and steel easily get rusted because of a chemical reaction with oxygen and moisture. On the other hand, aluminum forms a thin, healing oxide layer that guards the metal from more corrosion.

"Rust is a specific type of corrosion that affects iron-based metals like steel, while corrosion is a broader term referring to the gradual degradation of any metal through chemical reactions."

Knowing the difference between rust and corrosion is vital for picking the right materials, coatings, and care plans. This helps protect metal items from damage caused by the environment.

By understanding the unique chemical processes of rust and corrosion, we can find better ways to stop and lessen metal damage. This knowledge is very important for industries that need metal parts to last a long time. This includes construction, transportation, and manufacturing.

Can Aluminum Rust?

Understanding Aluminum's Chemical Properties

Aluminum is different from iron because it doesn't rust like iron does. When iron meets air and water, it turns into iron oxide, or rust. But aluminum forms a protective layer of aluminum oxide on its surface.

This layer bonds with the metal, stopping corrosion and keeping the aluminum strong.

The Role of Iron in Rust Formation

Rust is a big problem for iron and steel, but not for aluminum. The main reason is iron. When iron meets air and water, it reacts to form iron oxide, or rust.

This rust layer peels off, showing more metal to keep oxidizing. This creates a cycle of corrosion.

Why Aluminum Behaves Differently

Aluminum's special behavior comes from its chemical makeup. Pure aluminum reacts quickly and forms a protective oxide layer when it meets air or water.

This layer sticks to the surface, stopping corrosion resistance. Iron, on the other hand, doesn't form a protective layer as well, leading to rust.

| Property | Aluminum | Iron |

|---|---|---|

| aluminum properties | Highly reactive, forms protective oxide layer | Reactive, forms iron oxide (rust) that flakes off |

| iron oxide | Bonds to the surface, preventing further corrosion | Flakes off, exposing fresh metal to continued oxidation |

| aluminum oxide layer | Chemically bonded to the surface, providing effective protection | Does not form a similarly effective oxide layer |

In short, aluminum and iron are different because of their chemical properties and oxide layers. Iron is more likely to rust, but aluminum's special traits make it resistant to corrosion.

How Aluminum Oxidation Works

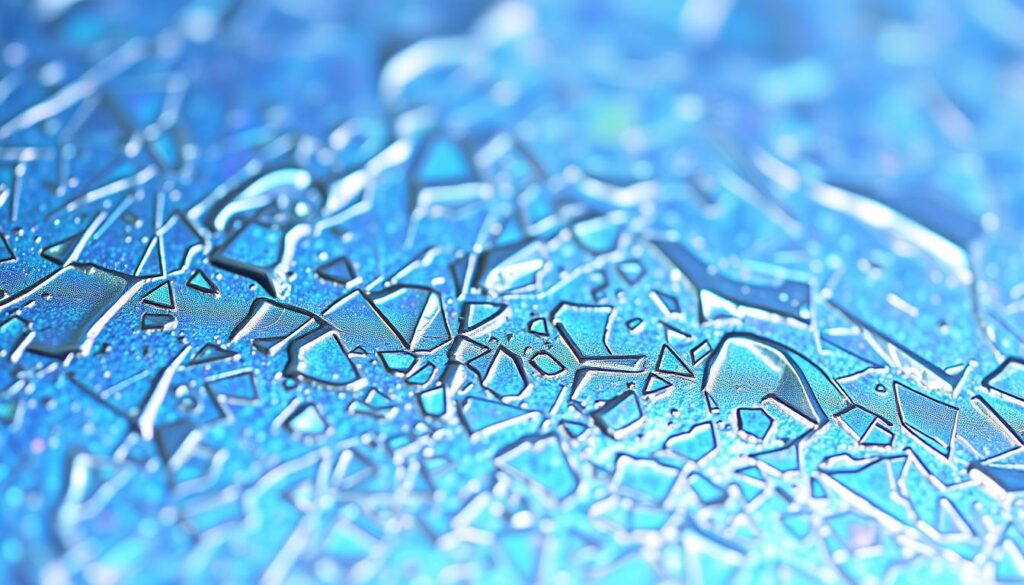

Aluminum is a special metal that doesn't rust. Unlike iron, which rusts and forms a reddish-brown coating, aluminum forms a protective layer. This layer, called aluminum oxide, stops corrosion in its tracks.

The aluminum oxide film is incredibly thin, just 4 nanometers thick. Yet, it offers great protection against corrosion. This process, called passivation, shows how unique aluminum's chemical properties are.

The speed of aluminum oxidation changes based on several factors. These include the type of aluminum alloy, its surface finish, and the environment it's in. In dry, sandy soil, aluminum doesn't corrode much. But in wet, acidic, or alkaline places, it can corrode more.

"Aluminum forms a stable oxidized layer that protects against corrosion, unlike iron that rusts in the presence of oxygen and water."

Even though aluminum is mostly resistant to corrosion, it can still be affected by certain chemicals. For example, sulfates or chlorine can harm it. Acid rain in cities or salt spray near the coast can also cause problems. In these situations, the oxide layer can break down, leading to pitting or crevice corrosion.

To make aluminum even more resistant to corrosion, there are surface treatments like anodizing. This method creates a thicker, more durable aluminum oxide layer. It helps the metal withstand weathering and environmental factors better.

Types of Aluminum Corrosion

Aluminum is known for its resistance to corrosion. Yet, it can still face different types of damage. Galvanic corrosion and pitting corrosion are two main types. Environmental factors like pH levels, chlorides, and sulfides also play a big role in speeding up corrosion.

Galvanic Corrosion in Aluminum

Galvanic corrosion happens when aluminum meets a different metal. This forms an electrical circuit. It often occurs when aluminum is paired with metals like steel or copper in moist environments.

The metals' different electrochemical potentials cause a flow of electrons. This flow leads to the corrosion of the less noble aluminum.

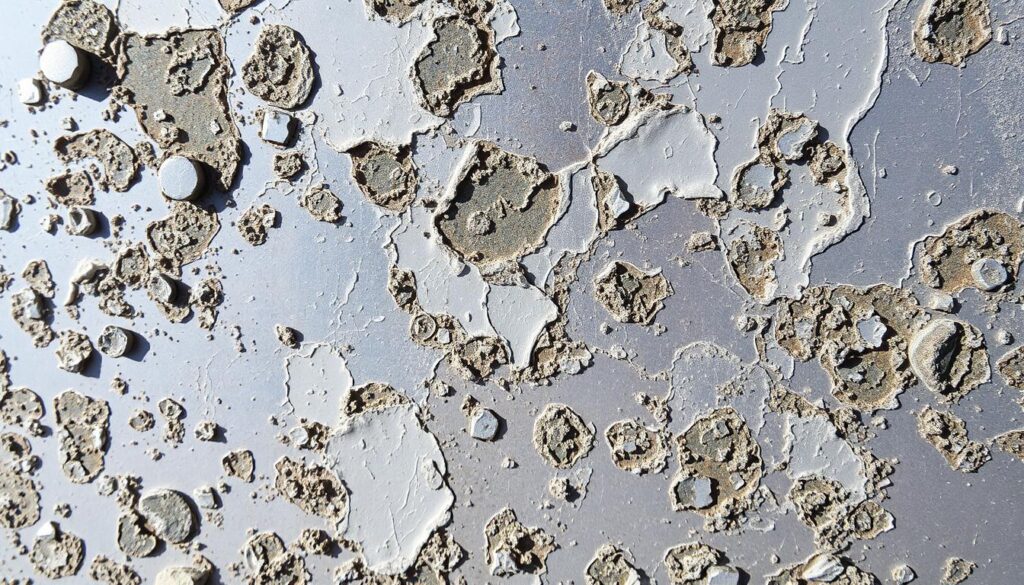

Pitting Corrosion

Pitting corrosion is a localized damage that can go deep into aluminum. It's usually caused by the breakdown of the protective oxide layer. This breakdown is often due to chlorides or other aggressive ions in the environment.

Environmental Factors Affecting Corrosion

The pH levels, chlorides, and sulfides in the environment greatly affect aluminum corrosion. The best pH range for untreated aluminum is between 4.5 and 8.5. Levels outside this range can harm the protective oxide layer.

Chlorides and sulfides can also damage the oxide layer. This makes aluminum more prone to pitting and other corrosion types.

"Understanding the various types of aluminum corrosion and the environmental factors that contribute to it is essential for designing and maintaining aluminum-based structures and components."

Comparing Aluminum and Steel Corrosion

Aluminum and stainless steel have different strengths when it comes to fighting corrosion. Stainless steel creates a strong chromium oxide layer, making it better than regular steel at resisting corrosion. Aluminum, on the other hand, forms an aluminum oxide layer that protects it well in many environments.

Stainless steel can handle very high temperatures, up to 2500°F (1370°C). This makes it perfect for situations where things get very hot. Aluminum, however, can only handle temperatures up to 400°F (205°C).

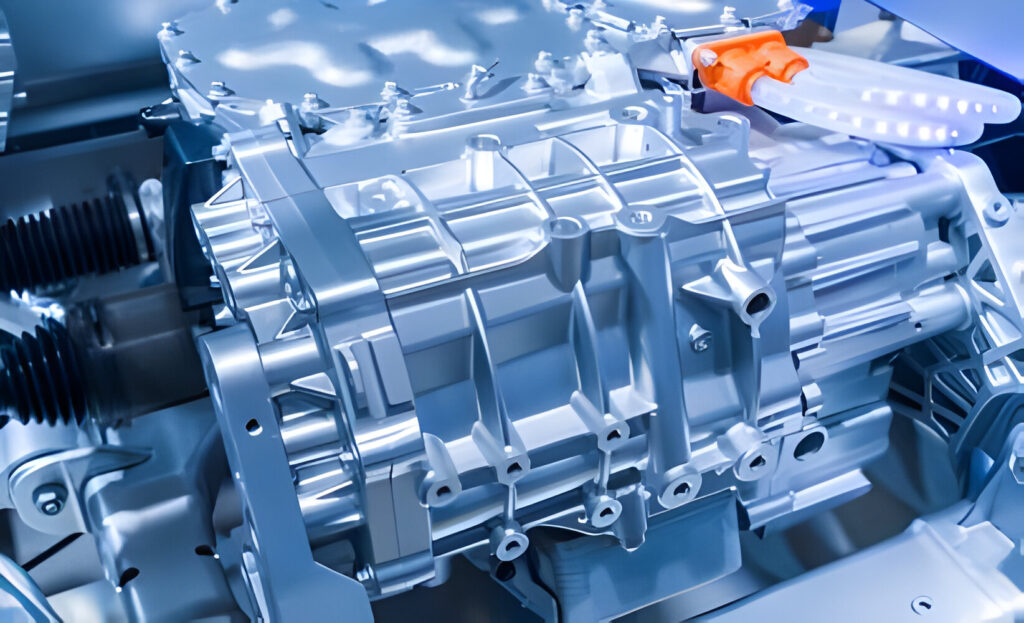

But aluminum is lighter than steel, about three times lighter. This is great for industries where weight matters a lot, like in cars and airplanes.

| Property | Aluminum | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Excellent | Superior |

| Heat Tolerance | Up to 400°F (205°C) | Up to 2500°F (1370°C) |

| Strength-to-Weight Ratio | Excellent | Good |

| Machinability | Easy | Moderate |

| Cost | Moderate | Higher |

Choosing between aluminum and stainless steel depends on what you need. Do you need something that fights corrosion well, is strong, light, and affordable? Both materials are used in many fields, like building, cars, and sports gear.

Protecting Aluminum from Corrosion

Aluminum is strong and versatile, but it can corrode if not protected. Luckily, there are ways to keep aluminum safe from corrosion. These include surface treatments and maintenance tips.

Surface Treatment Options

Anodizing is a top choice for protecting aluminum. It makes the metal's surface stronger and looks better. This method also boosts the metal's corrosion resistance.

Painting and powder coating are also great. They add a layer of protection and let you choose the look of your aluminum parts.

Maintenance Best Practices

Keeping aluminum clean is key to preventing corrosion. Regular cleaning removes dirt and salt. It keeps the metal safe. Also, stay away from harmful chemicals to keep aluminum durable for longer.

With the right treatments and care, aluminum stays corrosion-free. It will keep working well for you.

"Proper surface treatment and regular maintenance are the keys to protecting aluminum from corrosion and ensuring its long-term performance."

Conclusion

Aluminum doesn't rust, but knowing how it corrodes is key. It's great for many fields because it resists corrosion well. This makes it perfect for buildings, planes, and boats.

At KT-Foundry, we're experts in aluminum work. We help you choose and use aluminum for your projects. Our knowledge ensures your aluminum projects will last and perform well.

The need for light, durable, and green materials is rising. Aluminum fits this bill well. We're always looking for better ways to use aluminum. Together, we can make innovative, lasting, and eco-friendly solutions.