Using a stainless steel kitchen table for welding is a practical consideration, but it comes with specific advantages and challenges. Stainless steel is a durable and versatile material, making it an appealing choice for various applications, including welding. However, understanding the nuances of using such a table for welding is crucial to ensure safety and effectiveness.

Why Consider a Stainless Steel Kitchen Table for Welding?

Stainless steel is resistant to corrosion and heat, making it an ideal surface for welding projects. Its non-porous nature ensures that it doesn’t absorb contaminants, which is beneficial when maintaining a clean welding environment. Furthermore, stainless steel tables are often sturdy, providing a stable platform for welding tasks.

Product Details and Practical Applications

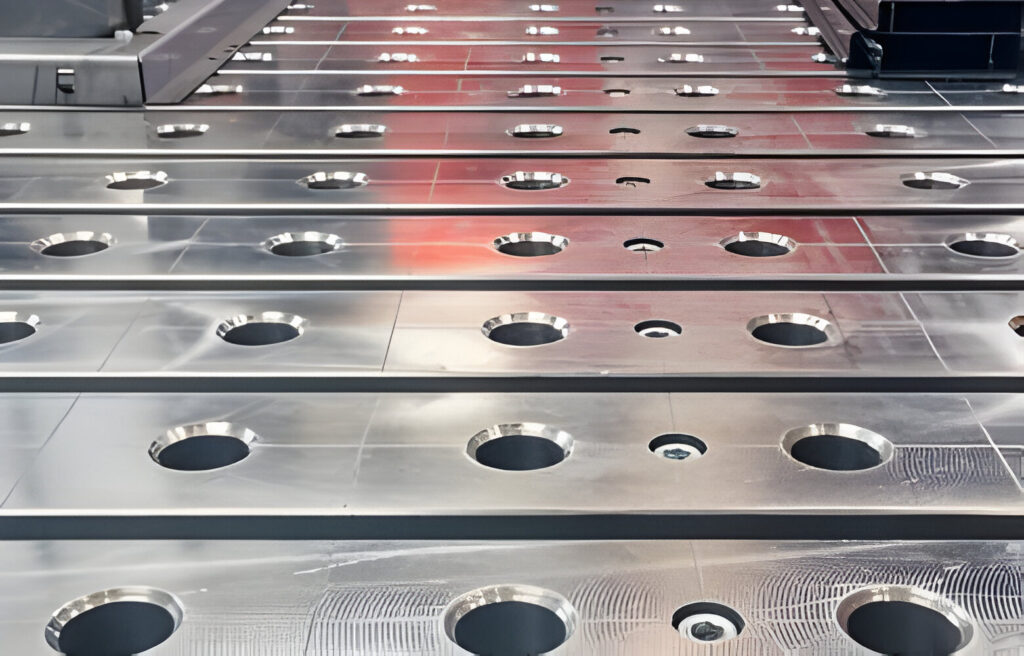

- Durability and Stability: Stainless steel tables, typically found in kitchens, are built to withstand heavy use and high temperatures. This makes them suitable for welding applications where heat and stability are paramount. These tables are often equipped with robust legs and supports, ensuring they can bear the weight of welding equipment and workpieces.

- Surface Cleanliness: The non-porous surface of stainless steel is easy to clean and maintain. This characteristic is vital in welding, where contamination from oils and other substances can compromise weld quality. A stainless steel table can be quickly wiped down, ensuring a clean work surface every time.

- Heat Resistance: Stainless steel’s ability to resist high temperatures without deforming makes it a suitable material for welding tables. This property is crucial when performing tasks that generate significant heat, such as arc welding or TIG welding.

Considerations and Alternatives

While stainless steel kitchen tables have many advantages, there are also some considerations to keep in mind. For instance, stainless steel can reflect the welding arc, potentially causing eye strain. To mitigate this, it’s essential to use proper welding helmets and screens.

Additionally, grounding is a critical aspect of welding safety. Ensuring that your stainless steel table is properly grounded can prevent electrical hazards. If you're considering mounting additional equipment, such as a grinder, to your welding table, stainless steel provides a solid and secure base.

Alternative Materials and Configurations

- Aluminum Work Tables: Can you use aluminum work tables as a welding table? While aluminum is lightweight and corrosion-resistant, it has a lower melting point than stainless steel, which can be a disadvantage in high-heat welding scenarios. However, for lighter welding tasks, aluminum can be a viable option.

- Cast Iron Welding Tables: Can you make a welding table from cast iron? Cast iron is another excellent material for welding tables due to its durability and heat resistance. It also has a rougher surface, which can help in securing workpieces.

- Grounding and Casters: Does a welding table need to be grounded? Yes, grounding is essential to prevent electrical hazards. Additionally, consider whether your welding table will have casters. Can a welding table have non-metal casters or rubber casters? Non-metal or rubber casters can be used, but they must be capable of withstanding the weight and heat of welding operations.

- Customization and Modifications: Can I mount a grinder to a welding table? Yes, and stainless steel tables are particularly suited for such modifications due to their strength and stability.

Contact Us

At KT-Foundry, we offer a range of welding tables and accessories designed to meet the needs of both amateur and professional welders. Whether you’re looking for a stainless steel table or exploring other materials like cast iron or aluminum, our products are crafted to deliver performance and durability. Visit our website to explore our offerings and contact us for more information.