At KT-Foundry, we focus on creating custom stainless steel castings that meet high standards. Our air-melt casting method lets us make parts up to 1,000 pounds. This meets the needs of the aviation, aerospace, and industrial gas turbine markets.

We have a strong quality management system. This includes ISO 9001:2015, AS9100 Rev D, and Nadcap certifications. We're ready to tackle your toughest stainless steel casting projects.

We use our knowledge of many stainless steel alloys. This includes Series 300, Series 400, 15-5PH, and 17-4PH. We work with our clients to create solutions that fit their needs. Our custom stainless steel castings offer corrosion resistance, wear resistance, and more.

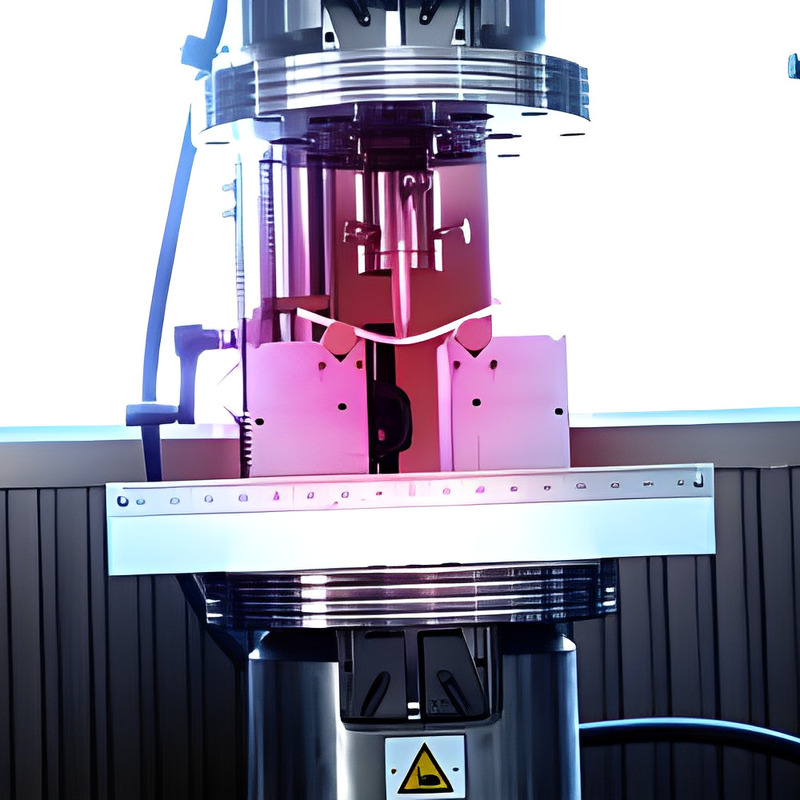

We use advanced tools for rapid prototyping and casting simulation. This ensures our designs are precise and waste is reduced. Our dedication to innovation and customer service makes us a reliable partner for custom casting needs.

What Are Custom Stainless Steel Castings?

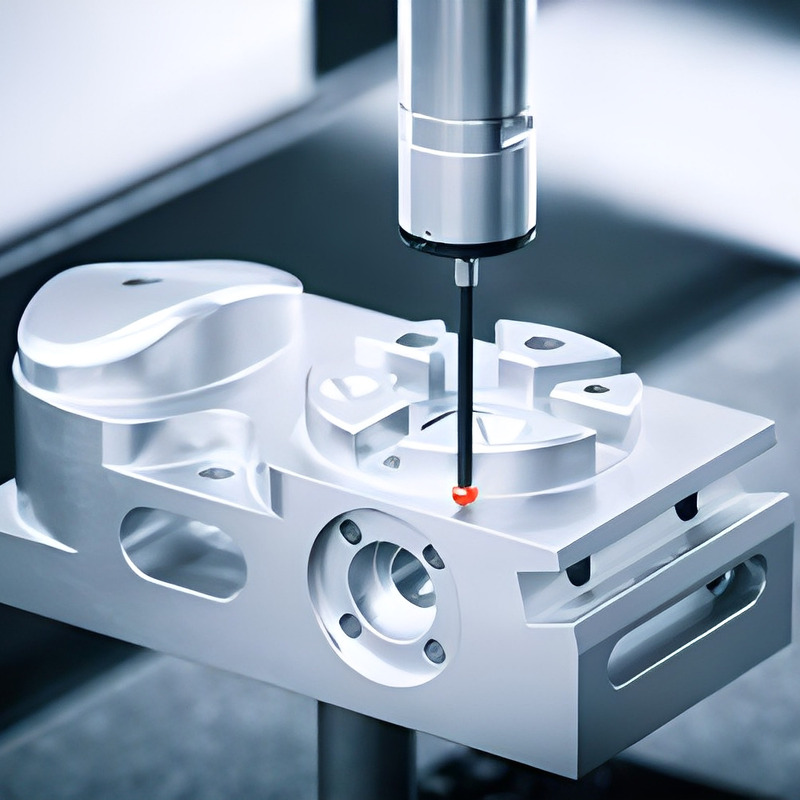

Stainless steel castings are made through a special process called investment casting. This method allows for flexible designs and uses very little material. It starts with wax patterns, then builds ceramic molds, and finally pours in molten stainless steel. This creates detailed, precise parts.

Custom stainless steel castings go beyond this. They offer solutions that fit exactly what a project needs.

The Stainless Steel Casting Process

The process starts with making wax patterns that look like the final part. These patterns are then covered in ceramic to make a mold. After that, molten stainless steel is poured in, melting the wax and leaving the part behind.

Custom Stainless Steel Castings vs. Standard Castings

Standard castings are made in a general way. But custom stainless steel castings are made just for a specific design. This means they can be very precise and have tight tolerances. They can also make complex shapes consistently.

Custom castings also use the right materials for each job. This makes them the most cost-effective choice for each project.

Advantages of Tailored Solutions

The main benefits of custom stainless steel castings are:

- Enhanced precision for complex designs and tight tolerances

- Material optimization for performance and cost-effectiveness

- Industry-specific solutions tailored to unique challenges

By teaming up with clients, makers can create unique stainless steel casting solutions. These solutions meet specific needs and give a competitive edge.

Benefits of Custom Stainless Steel Castings

Custom stainless steel castings are perfect for complex designs. Our team can make intricate shapes and complex designs. This ensures your projects are top-notch. We use various stainless steel grades like 304, 316, 410, and 420 for better performance and cost.

Our solutions are made for different industries. Whether it's aerospace, automotive, medical, marine, or industrial equipment, we have you covered. Our castings are strong and resistant to corrosion. This means your components will last long and perform well under tough conditions.

| Stainless Steel Grade | Tensile Strength (PSI) | Yield Strength (PSI) |

|---|---|---|

| 303 (CF-20) | 65,000 - 75,000 | 30,000 - 35,000 |

| 304L (CF-3) | 70,000 - 85,000 | 40,000 - 50,000 |

| 316L (CF-8M) | 70,000 - 85,000 | 40,000 - 50,000 |

| 410 (CA-15) | 95,000 - 200,000 | 75,000 - 160,000 |

| 17-4 PH | 150,000 - 190,000 | 140,000 - 160,000 |

Our custom stainless steel casting solutions can take your projects to the next level. We focus on precision casting and near net shape performance. This ensures your components are strong and resistant to corrosion. Choose us for the best stainless steel grades and unlock your project's full potential.

How Custom Stainless Steel Castings Are Made

At [https://kt-foundry.com/valve-body-casting/], we start with a team effort and design optimization with our clients. We use cutting-edge tech like rapid prototyping and ProCAST software. This helps us fine-tune the design to fit their exact needs.

Designing the Mold and Creating Wax Patterns

Then, we design the mold and make wax patterns that match the final product. This careful step ensures the casting process produces parts with high accuracy and detail.

Custom stainless steel castings are widely used across industries:

| Industry | Common Applications |

|---|---|

| Automotive | Engine components, exhaust systems |

| Aerospace | Structural fittings, turbine blades |

| Medical | Surgical instruments, diagnostic equipment |

| Industrial | Pumps, valves, and heat-resistant components |

Quality Assurance and Rigorous Testing

We have a strict quality management system to ensure top-notch quality. This includes:

- Non-Destructive Testing (NDT)

- Radiography

- Penetrant testing

- Heat treatment

- Welding inspections

Our expertise in wax pattern creation, ceramic mold design, and quality management systems helps us deliver custom stainless steel castings. These meet the highest standards and performance needs.

Applications of Custom Stainless Steel Castings

Custom stainless steel castings are changing many industries. They are used in automotive, aerospace, medical, marine, and industrial equipment. They can handle high stress and resist corrosion in tough environments.

Industries Benefiting from Custom Solutions

Our castings are versatile and adaptable. We've made many parts, like pump and valve components, compressor parts, and more. They are used in trains, mining, and aerospace too.

Successful Custom Projects

We've worked on many successful projects. For example, we made turbo manifolds for a car company. They improved engine performance and lasted long on the road.

In the medical field, we helped a company make precise components. These met strict standards and worked well under heavy use.

Our custom stainless steel castings can help you in many industries. They offer performance, durability, and precision. This helps you stay competitive.

Conclusion

At KT-Foundry, we know how important tailored solutions are for stainless steel castings. Our custom parts give you a big advantage. They offer better precision, material use, and designs made just for your industry.

These benefits mean your parts will work better, last longer, and save you money. This is true for many different uses.

Our team is great at custom stainless steel casting. We focus on quality and follow strict steps. This means our clients get top-notch parts that meet their highest standards.

Whether you work in cars, planes, medicine, or something else, our custom parts can help. They can make your projects stand out and give you an edge in the market.

Why tailored solutions give you a competitive edge

Working with KT-Foundry means you get parts made just for you. They're made with the best precision, material use, and designs for your field. This leads to parts that work better, last longer, and save you money.

Call to action: Explore custom casting solutions with KT-FOUNDRY

Want to see how KT-Foundry's custom parts can help you? Check out what we can do and get in touch with our team. Let's work together to make the high-quality parts your projects need.

KT--Casting

Bring Your Designs to Reality– Experience Custom Perfection with On-Demand Casting!