Motor housing serves as the protective enclosure for the internal components of an electric motor, ensuring its efficient operation and longevity. Often referred to as motor casing or motor housing cover, this critical component plays a vital role in safeguarding the motor against environmental factors, mechanical stress, and contamination. In this article, we delve into the intricacies of motor housing, shedding light on its significance and functionality.

Understanding Motor Housing

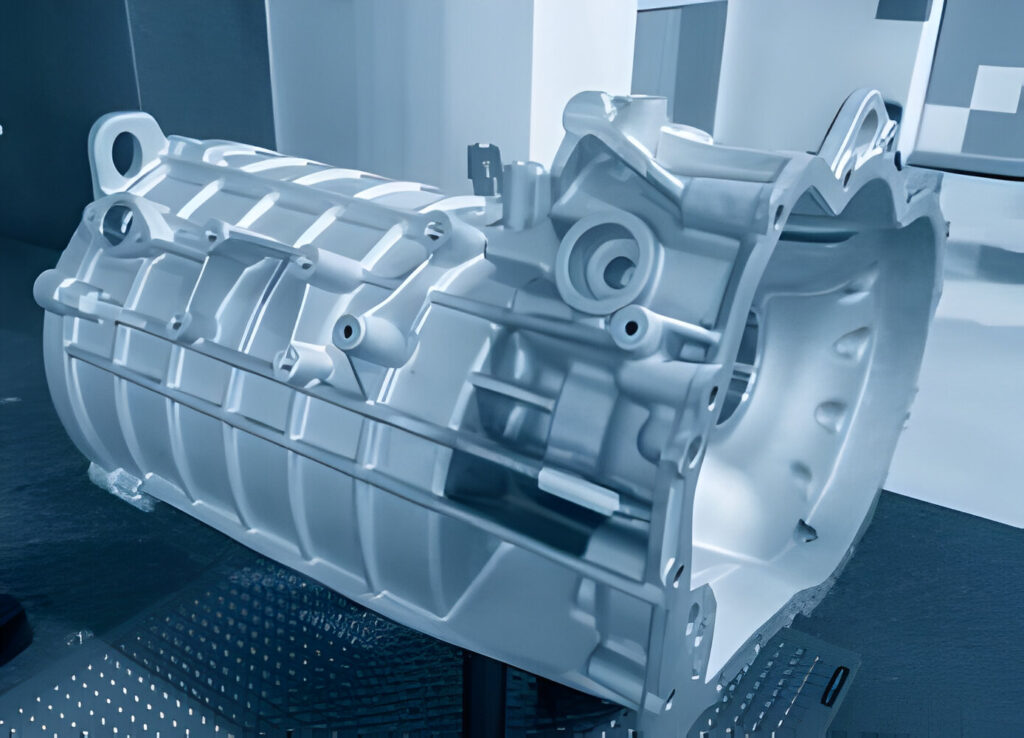

Motor housing, sometimes known as electric motor housing or electric motor casing, is the outer shell that encloses the essential components of an electric motor. It is typically made from durable materials such as aluminum, cast iron, or stainless steel to provide robust protection against external elements. The design and construction of motor housing parts are crucial in maintaining the integrity of the motor and ensuring its reliable performance in various applications.

Key Components of Motor Housing

Motor housing comprises several integral components, each serving a specific function to support the overall operation of the electric motor:

- Motor Casing: The main body of the housing, which encloses the motor's internal components and provides structural support.

- Motor Housing Cover: Also known as the end cover or end shield, this component seals the motor housing, protecting it from dust, debris, and moisture ingress.

- Motor Housing Casting: The process of manufacturing motor housing through casting ensures precision and durability, essential for withstanding the demands of industrial environments.

Importance of Motor Housing

The significance of motor housing cannot be overstated, as it directly impacts the performance, reliability, and longevity of electric motors. Here's why motor housing is essential:

- Protection: Motor housing acts as a shield, protecting sensitive internal components such as the stator, rotor, and bearings from damage caused by external factors like dust, dirt, moisture, and mechanical impact.

- Thermal Management: Efficient heat dissipation is crucial for maintaining optimal motor performance. Motor housing facilitates heat transfer away from the motor's components, preventing overheating and prolonging the motor's lifespan.

- Noise Reduction: By dampening vibrations and containing noise generated during motor operation, motor housing contributes to a quieter working environment, especially in noise-sensitive applications.

Choosing the Right Motor Housing Supplier

Selecting a reliable motor housing supplier is paramount to ensuring the quality and performance of electric motors. When choosing a supplier, consider the following factors:

- Experience and Expertise: Look for a supplier with extensive experience in manufacturing motor housing and a proven track record of delivering high-quality products.

- Customization Options: Opt for a supplier that offers customization options to meet specific requirements, such as size, material, and additional features.

- Quality Assurance: Ensure that the supplier adheres to strict quality control standards throughout the manufacturing process, from material selection to final inspection.

Experience the KT Foundry Advantage

At KT Foundry, we specialize in providing top-quality motor housing solutions tailored to meet the diverse needs of our clients. With years of experience in the industry, state-of-the-art facilities, and a team of skilled professionals, we are committed to delivering excellence in every aspect of our products and services.

Explore our website (kt-foundry) to learn more about our motor housing offerings and how we can assist you in optimizing the performance and durability of your electric motors. Contact us today to discuss your requirements and experience the KT Foundry advantage firsthand.