When it comes to setting up a workshop, one of the most crucial pieces of equipment is a sturdy, reliable welding table. For many professionals and DIY enthusiasts, a custom built welding table is the ideal solution, offering tailored functionality and durability. Whether you are looking for a custom welded table for precise projects or need a robust platform to handle heavy-duty tasks, custom welding tables can meet your specific needs.

Why Choose a Custom Built Welding Table?

A custom built welding table offers numerous advantages over standard models. Firstly, these tables are designed to fit the specific dimensions of your workspace, ensuring maximum efficiency. You can customize the height, width, and length to suit your comfort and the scope of your projects. Additionally, custom welding tables can be fitted with various features such as clamps, adjustable legs, and built-in storage for tools and materials, enhancing functionality and organization.

Durability and Material Quality

Custom built welding tables are typically constructed from high-quality materials such as stainless steel or reinforced steel, which provide superior durability and longevity. The robust nature of these materials means the table can withstand the high temperatures and heavy impacts associated with welding tasks. A custom welded table is designed to handle intensive use, ensuring it remains a reliable part of your workshop for years to come.

Versatility and Practical Applications

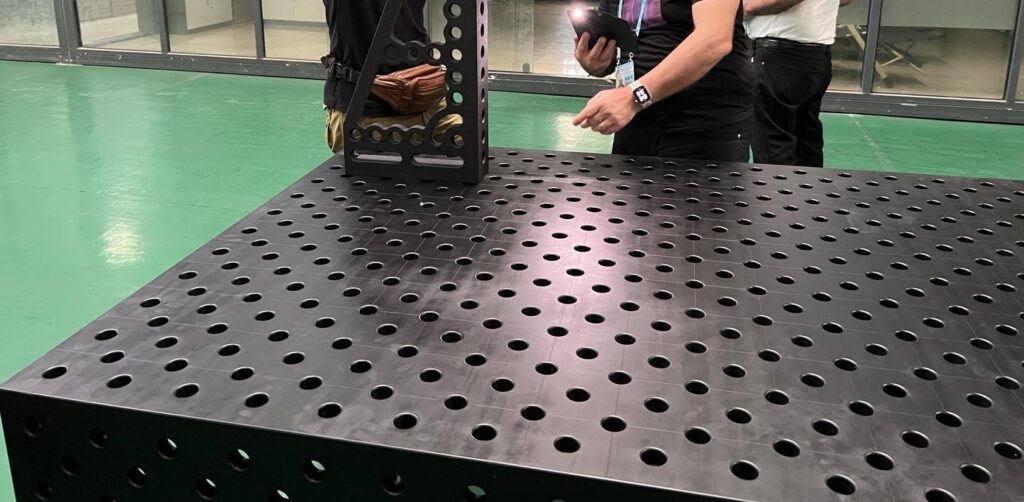

The versatility of custom welding tables makes them suitable for a wide range of applications. Whether you are involved in metal fabrication, automotive repair, or artistic metalwork, a custom built welding table can be tailored to accommodate various tasks. For instance, a table with a perforated top allows for easy clamping and precise positioning of workpieces, which is essential for complex welding projects. Additionally, the ability to add modular accessories like vices, jigs, and fixtures further enhances the table’s adaptability.

Case Study: Enhancing Productivity with Custom Welding Tables

Consider the example of KT Foundry, a renowned workshop specializing in custom metal fabrication. By investing in custom built welding tables, KT Foundry was able to streamline their operations significantly. The tables were designed with specific features such as adjustable heights and integrated storage, which reduced setup times and improved workflow. As a result, KT Foundry saw a noticeable increase in productivity and a decrease in project turnaround times, ultimately leading to higher customer satisfaction.

Choosing the Right Custom Built Welding Table for Your Needs

When selecting a custom built welding table, it is important to consider your specific requirements and the nature of your work. Start by evaluating the size of your workspace and the types of projects you typically undertake. Think about the features that would be most beneficial, such as mobility for a flexible workshop layout, or heavy-duty materials for high-impact tasks. Consulting with a specialist can also provide valuable insights and help you design a table that perfectly fits your needs.

Invest in Quality and Precision

A custom built welding table is more than just a piece of furniture; it is an investment in quality, precision, and efficiency. By tailoring your table to your specific requirements, you can create a more productive and organized workspace. If you are ready to enhance your workshop with a custom welded table, visit KT Foundry today. Our team of experts is ready to help you design and build the perfect welding table to meet your needs. Contact us through our website to learn more and start your customization process.