A welding rotary table is a pivotal tool in modern fabrication and manufacturing environments, offering enhanced precision, efficiency, and versatility in welding operations. Whether you are involved in small-scale projects or large industrial applications, a rotary welding table can significantly improve the quality and speed of your work. This article delves into the various aspects of welding rotary tables, highlighting their benefits, applications, and key features.

Understanding Welding Rotary Tables

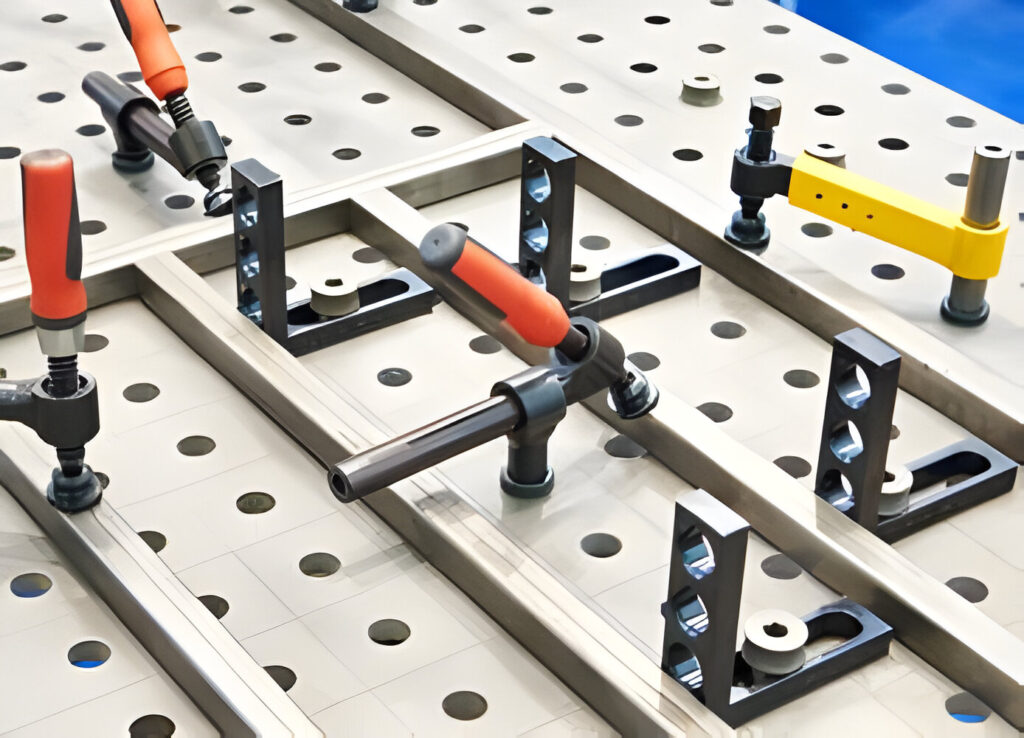

Welding rotary tables, also known as rotating welding tables, are designed to hold and rotate workpieces, allowing welders to perform welding operations with greater ease and accuracy. These tables are equipped with a rotating mechanism that provides a stable and controlled environment for welding, ensuring consistent welds and reducing the likelihood of errors.

Key Features and Benefits

- Precision and Control

One of the primary advantages of using a welding rotary table is the precise control it offers. With the ability to rotate the workpiece at a controlled speed, welders can achieve uniform welds around the entire circumference of the object. This precision is especially beneficial for complex welding tasks that require high accuracy. - Increased Efficiency

Welding rotary tables streamline the welding process by eliminating the need to manually reposition the workpiece. This not only saves time but also reduces the physical strain on welders. For instance, a 360 rotating welding table allows continuous welding operations without the need for frequent stops and adjustments, significantly boosting productivity. - Versatility in Applications

Rotary welding tables are versatile and can be used in various welding applications. They are particularly useful in industries such as automotive, aerospace, and construction, where precision welding is crucial. Additionally, customized rotary table ultrasonic welders are available for specialized applications, offering tailored solutions to meet specific industry requirements.

Product Details and Applications

Rotary Welding Table Build

Building a rotary welding table involves selecting the right components and ensuring robust construction to handle different workpiece sizes and weights. For example, a table top welding turntable mounting plate is essential for securing the workpiece firmly during rotation. Manufacturers often provide plans and kits for DIY enthusiasts interested in constructing their own welding tables, such as motor rotary welding table plans, which offer detailed instructions for building a reliable and efficient table.

Applications and Scenarios

Welding rotary tables are used in a variety of scenarios, from small workshops to large-scale industrial operations. A 100 rpm welding table, for instance, is ideal for high-speed welding tasks that require rapid rotations. In contrast, a manual rotating welding table is suitable for applications where precise control over the rotation speed is needed. These tables are also invaluable in automated welding systems, where they can be integrated with robotic arms and other automated equipment to enhance the welding process.

Manufacturing and Customization

Manufacturers of welding rotary tables offer a range of options to cater to different needs. From standard models to customized solutions, companies like rotary table ultrasonic welder manufacturers provide products that meet specific industry standards and requirements. Customized rotary tables can include features such as adjustable speeds, enhanced load capacities, and compatibility with various welding techniques, ensuring optimal performance in diverse applications.

FAQs

Q: What are the main advantages of using a welding rotary table?

A: The main advantages include increased precision, enhanced efficiency, and versatility in various welding applications.

Q: Can I build my own rotary welding table?

A: Yes, many manufacturers offer plans and kits for building your own rotary welding table, providing all the necessary components and instructions.

Q: Are there different types of welding rotary tables available?

A: Yes, there are various types, including manual and motorized tables, as well as specialized tables for ultrasonic welding and other specific applications.

Investing in a welding rotary table can greatly enhance the quality and efficiency of your welding operations. Whether you need a standard table or a customized solution, these tools offer the precision and control necessary for achieving high-quality welds. For more information on purchasing a welding rotary table, visit our website (kt-foundry) and explore our range of products designed to meet your welding needs.