Fuel oil pump houses are indispensable components in various industrial settings, serving as protective enclosures for fuel oil pump assemblies. In this article, we delve into the importance of fuel oil pump houses, their functions, and why selecting the right one is essential for optimal machinery performance.

Understanding Fuel Oil Pump Houses

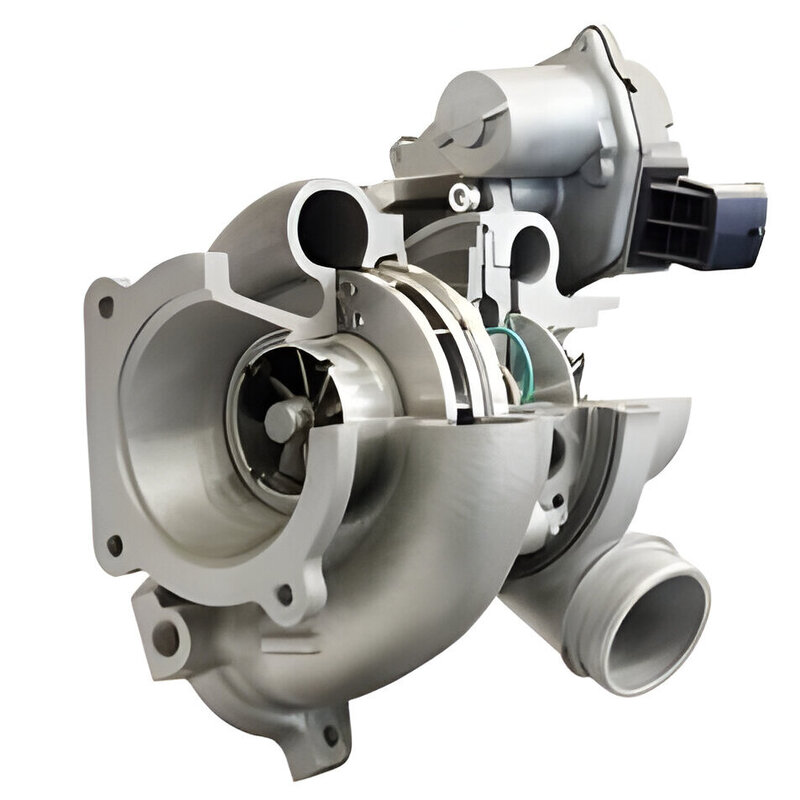

Fuel oil pump houses, also known as fuel oil pump housings, are critical elements in machinery systems that rely on fuel oil for operation. These houses provide a secure environment for the fuel oil pump assembly, protecting it from external elements and facilitating its efficient functioning.

Functions and Importance

The primary function of a fuel oil pump house is to safeguard the fuel oil pump assembly from damage caused by contaminants, debris, and environmental factors. By ensuring a sealed environment, the house prevents interference with the pump's operation, thereby extending its lifespan and reducing maintenance needs.

Furthermore, fuel oil pump houses contribute to the efficient operation of machinery by maintaining optimal conditions within the pump assembly. They help dissipate heat generated during pump operation, preserving the integrity of the fuel oil and ensuring consistent performance.

Selecting the Right Fuel Oil Pump House

Choosing the appropriate fuel oil pump house is crucial for maximizing machinery efficiency and longevity. Several factors must be considered during the selection process, including material composition, compatibility, and environmental conditions.

Material Composition

Fuel oil pump houses are typically constructed from materials such as cast iron, aluminum, or steel. Each material offers unique advantages. Cast iron houses are known for their durability and corrosion resistance, making them suitable for harsh industrial environments. Aluminum houses, on the other hand, are lightweight and offer excellent heat dissipation properties, making them ideal for applications where weight and temperature management are critical.

Compatibility and Fitment

When selecting a fuel oil pump house, compatibility with the pump assembly and machinery is paramount. The house must be designed to accommodate the specific dimensions and specifications of the pump, ensuring a secure and precise fit. Additionally, factors such as mounting provisions and sealing mechanisms should be considered to prevent leaks and maintain the integrity of the fuel oil system.

Environmental Considerations

The operating environment plays a significant role in determining the suitability of a fuel oil pump house. Factors such as temperature variations, exposure to chemicals, and vibration levels can impact the performance and longevity of the housing. Therefore, it is essential to choose a housing that can withstand the rigors of the operating environment without compromising functionality or durability.

In conclusion, fuel oil pump houses are vital components in industrial machinery systems reliant on fuel oil. By providing a protective enclosure for fuel oil pump assemblies, these houses help safeguard critical components and maintain optimal operating conditions. When selecting a fuel oil pump house, considerations such as material composition, compatibility, and environmental factors should be taken into account to maximize machinery efficiency and longevity.