Furnace blower motor housings may not be the first thing that comes to mind when considering home heating systems, but these components play a crucial role in ensuring the efficiency and reliability of furnaces. Situated within the furnace assembly, blower motor housings provide protection, support, and thermal management for the motor, facilitating the distribution of warm air throughout the home. In this article, we explore the significance of furnace blower motor housings, their construction, and why choosing the right one is essential for optimal heating performance.

Protective Enclosures for Motors:

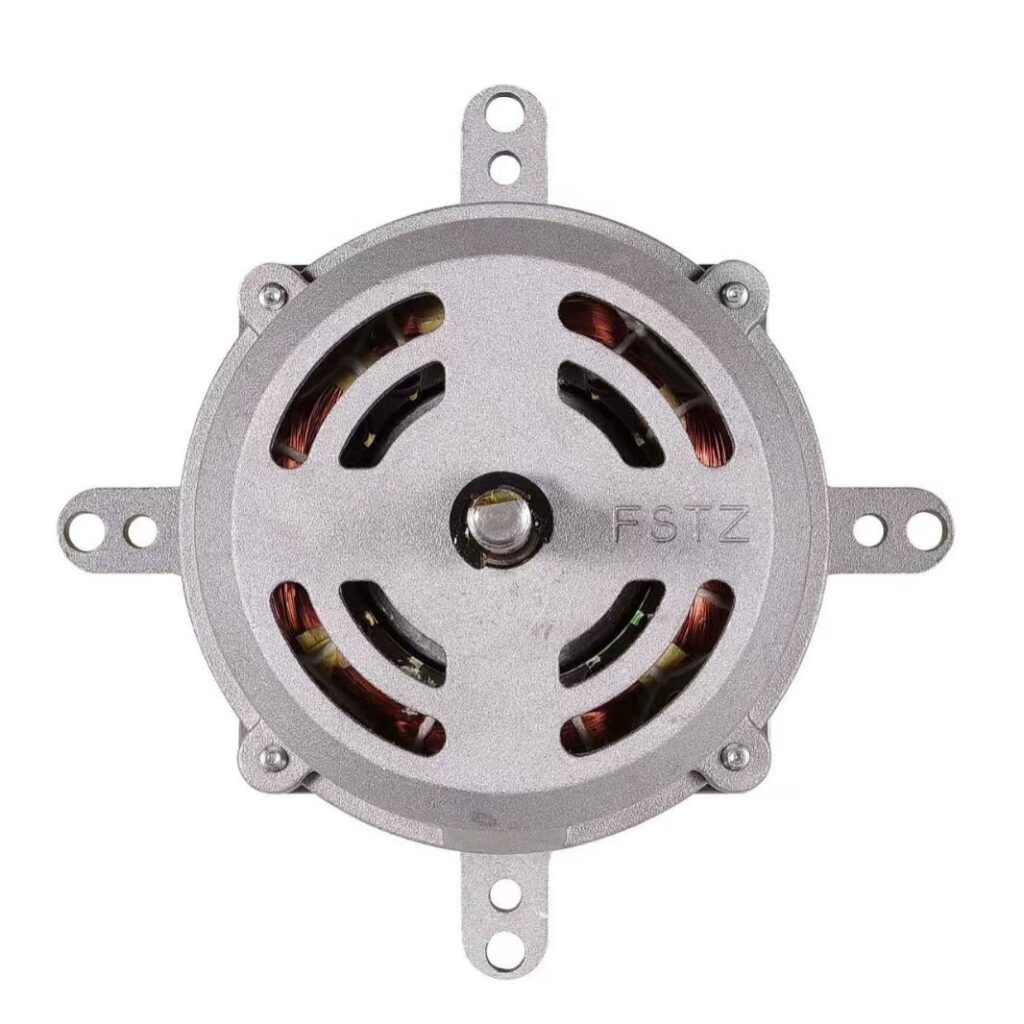

Furnace blower motor housings serve as protective enclosures for the motors that power the blower fans in heating systems. These housings shield the motor and its internal components from dust, debris, and other contaminants that could interfere with its operation. By providing a sealed environment, motor housings help maintain the integrity and longevity of the motor, reducing the risk of premature failure and costly repairs.

Facilitating Heat Dissipation:

Efficient heat dissipation is critical for the performance and longevity of furnace blower motors, especially during extended periods of operation. Motor housings are designed to dissipate heat generated by the motor, preventing overheating and ensuring optimal performance. Materials with high thermal conductivity, such as aluminum or steel, are often used in the construction of motor housings to enhance heat transfer and improve overall efficiency.

Noise Reduction and Vibration Control:

Furnace blower motors can produce noise and vibration during operation, which may be undesirable in residential settings. Motor housings are designed to minimize noise and vibration by dampening sound and providing a stable enclosure for the motor. Well-designed housings with vibration-absorbing materials help reduce noise levels, ensuring quiet and comfortable operation of the heating system.

Construction and Materials:

Furnace blower motor housings are typically constructed from durable materials such as steel, aluminum, or reinforced plastics. The construction of these housings may involve processes such as casting, machining, or stamping to achieve the desired shape and specifications. Additionally, motor housings may feature insulation materials to further improve thermal efficiency and reduce heat loss during operation.

Compatibility and Customization:

Motor housings for furnace blower motors come in various sizes, shapes, and configurations to accommodate different furnace designs and specifications. Whether it's a residential furnace or a commercial heating system, customers can find motor housings tailored to their specific requirements. Some manufacturers offer customization options, allowing customers to choose features such as mounting brackets, access panels, or airflow configurations to suit their needs.

Ensuring Reliable Heating Performance:

In summary, furnace blower motor housings play a vital role in ensuring the efficiency, reliability, and longevity of heating systems. By providing protection, heat dissipation, and noise reduction for the blower motor, these housings contribute to optimal heating performance and comfort in residential and commercial environments.

At KT Foundry, we specialize in the production of high-quality furnace blower motor housings designed to meet the demanding requirements of heating systems. With a focus on precision engineering, durability, and performance, our motor housings are trusted by homeowners, HVAC contractors, and manufacturers alike. Contact us today through our website to explore our range of furnace blower motor housing solutions and discover how we can help enhance the efficiency of your heating system.