In the realm of industrial machinery, the performance and longevity of pump systems are paramount. An integral component of these systems is the pump body, which plays a crucial role in housing and directing the flow of fluids. For industries requiring robust and reliable pump bodies, alloy pump body casting emerges as a preferred solution. At KT-Foundry, we specialize in offering the best-customized die casting service for pump bodies, ensuring top-notch quality and performance. Let's delve deeper into the realm of alloy pump body casting to understand its significance and advantages.

The Advantages of Alloy Pump Body Casting

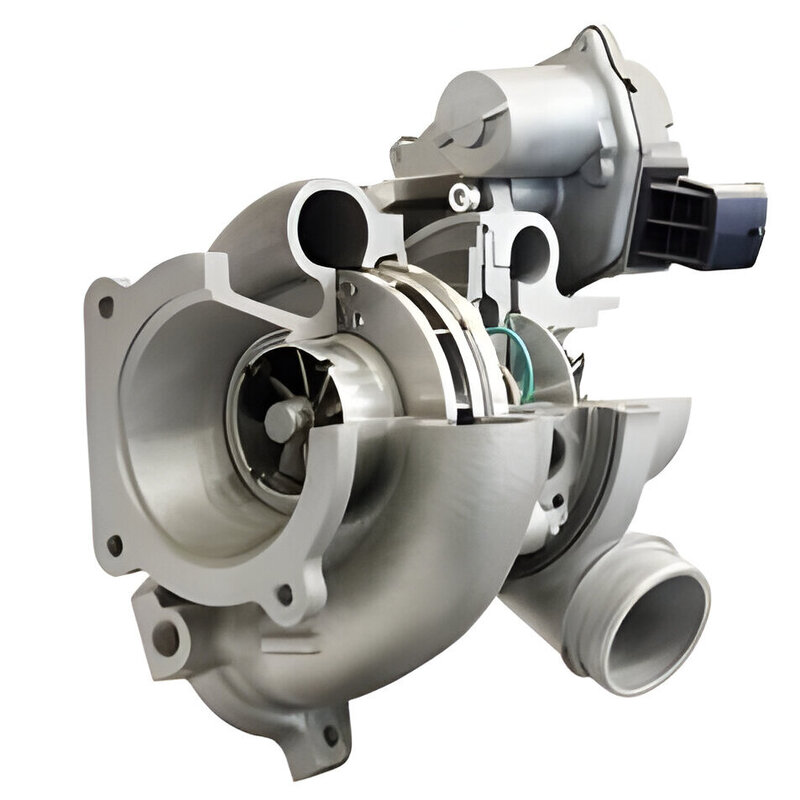

Alloy pump body casting involves the process of pouring molten alloy into a mold to create intricate pump body designs. This method offers several distinct advantages over alternative manufacturing techniques.

- Enhanced Strength and Durability: One of the primary benefits of alloy pump body casting is the ability to achieve superior strength and durability. By utilizing alloys such as aluminum, brass, or stainless steel, pump bodies can withstand high pressures and harsh operating conditions without succumbing to corrosion or mechanical stress. This ensures prolonged service life and reduced maintenance requirements, making alloy pump bodies an ideal choice for demanding applications.

- Complex Geometries and Customization: The die casting process allows for the creation of intricate pump body designs with precision and consistency. This means that manufacturers can tailor the pump bodies to meet specific performance requirements and spatial constraints. Whether it's optimizing flow dynamics or integrating mounting features, alloy pump body casting offers unparalleled flexibility in design customization.

- Cost-Effectiveness and Efficiency: Despite offering premium quality and customization options, alloy pump body casting remains a cost-effective manufacturing solution. The high repeatability of the die casting process results in minimal material waste and reduced machining requirements, leading to lower production costs. Additionally, the inherent efficiency of die casting ensures faster lead times, allowing businesses to streamline their supply chain and meet tight project deadlines.

Why Choose KT-Foundry for Pump Body Casting?

At KT-Foundry, we understand the critical role that pump bodies play in industrial applications, which is why we are committed to delivering excellence in alloy pump body casting. Here's why customers choose us for their pump body casting needs:

- Exceptional Quality Control: We adhere to stringent quality control measures throughout the casting process to ensure that each pump body meets the highest standards of performance and reliability. From material selection to final inspection, our experienced team meticulously monitors every aspect of production to minimize defects and deviations.

- Customization Capabilities: Whether you require a standard pump body design or a complex, custom solution, our team has the expertise and resources to fulfill your requirements. We work closely with clients to understand their unique specifications and design preferences, offering tailored solutions that optimize performance and efficiency.

- Competitive Pricing and Quotes: We believe that premium quality should not come at a premium price. That's why we offer competitive pricing for our alloy pump body casting services, ensuring that our customers receive exceptional value for their investment. Additionally, we provide transparent and detailed quotes, allowing clients to make informed decisions based on their budget and project scope.

Contact Us Today for Pump Body Casting Solutions

If you're in need of high-quality alloy pump body casting solutions, look no further than KT-Foundry. With our expertise, dedication to quality, and commitment to customer satisfaction, we are your trusted partner for all your pump body casting needs. Contact us today through our website to request a quote or learn more about our services.