In the realm of manufacturing precision components for pumps, the choice of materials and production methods plays a pivotal role in determining the product's efficiency, durability, and overall performance. Among various manufacturing techniques, die casting stands out as a reliable method for creating intricate pump bodies that meet stringent industry standards. When seeking the best customized die casting service for pump bodies, understanding the nuances of cast pump bodies and the significance of casting pump body quotes becomes imperative.

Unveiling the Precision of Cast Pump Bodies

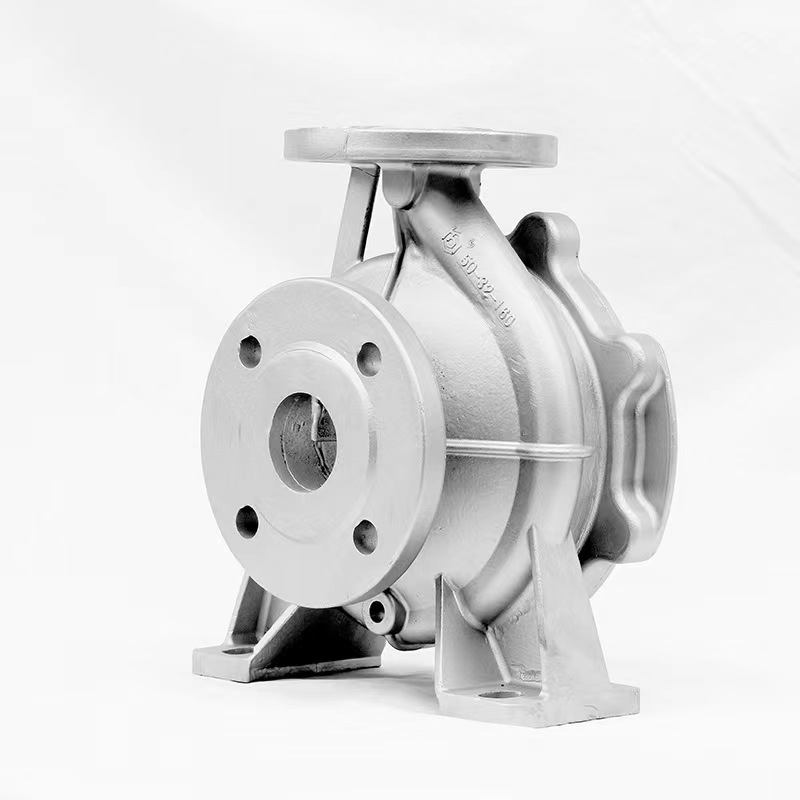

Cast pump bodies serve as the cornerstone of efficient pump systems, ensuring seamless fluid movement and optimal performance. These components are crafted with precision to accommodate the unique specifications and requirements of diverse applications, ranging from industrial processes to commercial operations.

Utilizing advanced die casting techniques, manufacturers can produce pump bodies with intricate designs and superior dimensional accuracy. By employing custom molds, intricate features such as internal channels, mounting points, and sealing surfaces can be seamlessly integrated into the casting, optimizing functionality and minimizing post-processing requirements.

Moreover, the versatility of die casting enables the production of pump bodies in various materials, including aluminum, zinc, and magnesium alloys. Each material offers distinct advantages in terms of strength, corrosion resistance, and thermal conductivity, allowing engineers to select the most suitable option based on the application's demands.

Maximizing Value with Casting Pump Body Quotes

When embarking on a project requiring customized pump bodies, obtaining accurate casting pump body quotes is essential for budgeting and decision-making purposes. A comprehensive quote not only outlines the cost of production but also provides valuable insights into the manufacturing process, material selection, and lead times.

At KT Foundry, we specialize in delivering premium die casting services tailored to the unique needs of our clients. Our team of experts meticulously analyzes project requirements to provide detailed quotes that reflect the intricacies of each casting job. Whether it's a single prototype or a large-scale production run, our transparent pricing ensures that customers receive exceptional value without compromising on quality.

Furthermore, our commitment to continuous improvement and efficiency allows us to offer competitive pricing without sacrificing precision or reliability. By leveraging state-of-the-art equipment and streamlined processes, we optimize production cycles and minimize overhead costs, passing the savings directly to our clients.

Experience Excellence with the Best Customized Die Casting Service

At KT Foundry, we take pride in our ability to exceed customer expectations through excellence in craftsmanship and customer service. With decades of experience in the die casting industry, we have earned a reputation for delivering high-quality pump bodies that consistently outperform traditional alternatives.

Our dedication to innovation drives us to explore new techniques and technologies, ensuring that our clients benefit from the latest advancements in die casting. Whether it's incorporating design enhancements for improved efficiency or implementing advanced materials for enhanced durability, we are committed to pushing the boundaries of what's possible in pump body manufacturing.

Moreover, our customer-centric approach means that we prioritize communication, responsiveness, and collaboration throughout the entire project lifecycle. From initial consultation to final delivery, our team works closely with clients to understand their needs, address concerns, and provide tailored solutions that exceed expectations.

Conclusion

In the realm of pump manufacturing, the choice of pump bodies plays a critical role in determining system performance and reliability. With the best customized die casting service, manufacturers can leverage the precision and versatility of die casting to create pump bodies that meet the most demanding requirements.

By partnering with KT Foundry, customers gain access to a team of experts dedicated to delivering excellence in every aspect of die casting production. From meticulous design analysis to transparent quoting and seamless execution, we are committed to empowering our clients with high-quality pump bodies that drive success in their applications.

Experience the difference with KT Foundry and unlock the full potential of your pump systems. Contact us today to discuss your project requirements and discover how our customized die casting services can elevate your manufacturing capabilities.